CLPISOVG220:Fuchs Renolin CLP220

CLPISOPGVG220: Fuchs Renolin PG220

CLPISOPGVG460: FuchsRenolin PG460

CLPISOPAOVG68:Fuchs Renolin Unisyn XT68

CLPISOPAOVG220:Fuchs Renolin Unisyn XT220

CLPISOPAOVG460:Fuchs Renolin Unisyn CLP460

CLPISOEVG220:FuchsPlantogearS220

CLPISOH1VG100:KlüberKlübersynthUH16100

CLPISOH1VG460:CastrolOptilebGT1800/460

If, following agreement, the gearbox is lled at the factory with special lubricant for the

special applications referred to above, the lubricant must be shown on the rating plate.

12.3.24.11 Change the roller bearing grease

The roller bearings are lubricated in the factory with the greases listed in the table.

Renew the grease quantify for grease-lubricated bearings with each oil change.

Clean the bearing before lling the bearing with fresh lubricant.

In the case of bearings on the output shaft or intermediate shafts, the grease quantity must

ll 2/3, and in the case of bearings on the input side, 1/3 of the space between the rolling

elements.

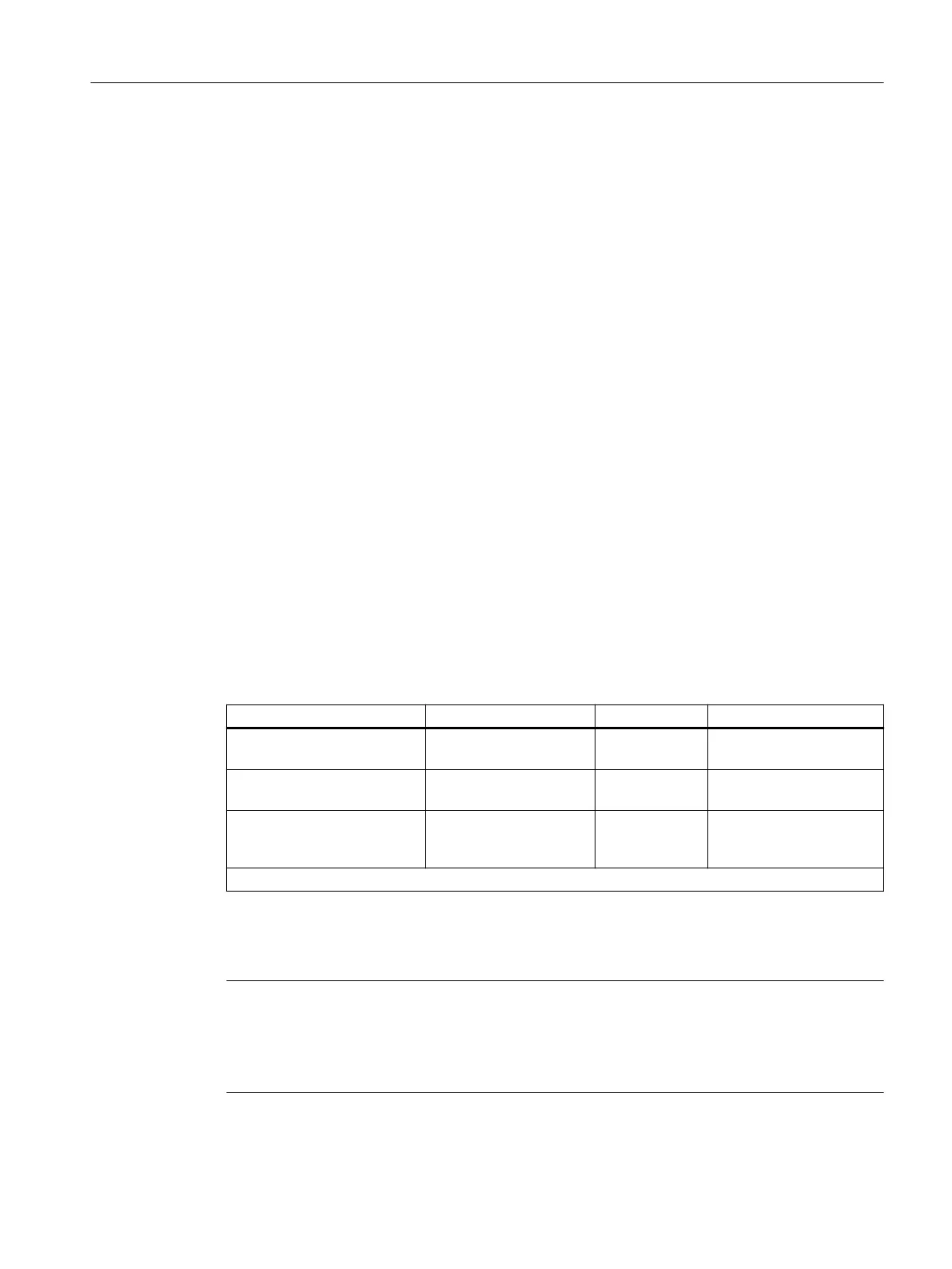

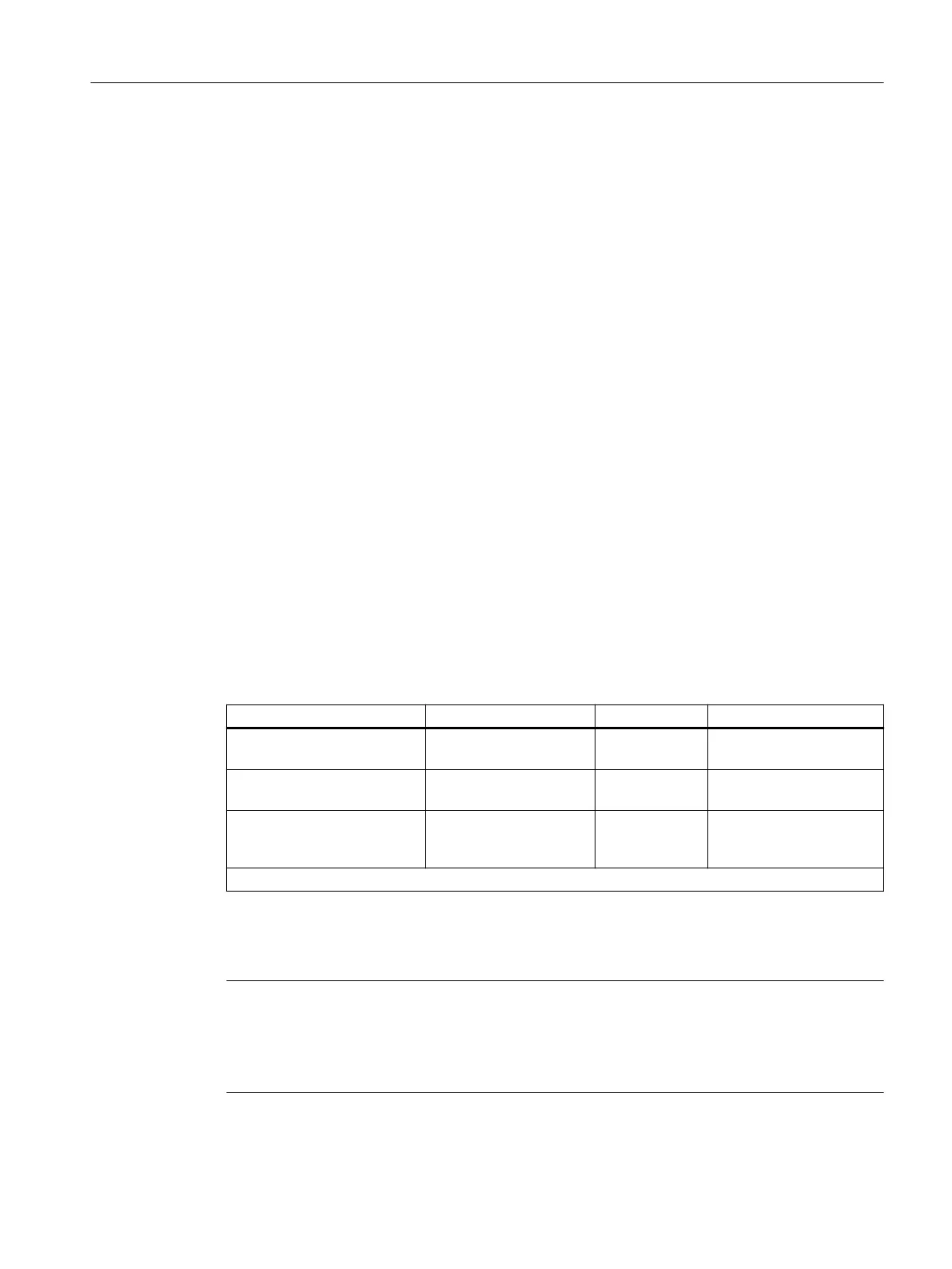

Table 12-44 Roller-bearing and shaft-sealing-ring grease

Fields of application Ambient temperature Manufacturer Type

Standard -40°Cto+80°C Klüber

Fuchs

PetamoGHY133N

RenolitCX‑Tom15

1)

Foodstu-compatible for the

food industry

-30°Cto+60°C Bremer & Leguil CassidaGreaseGTS2

Biologically degradable, for

agriculture, forestry and wa‐

ter industries

-35°Cto+60°C Fuchs Plantogel2S

1)

Rolling-bearing grease based on a semi-synthetic base oil.

12.3.24.12 Service life of the lubricants

Note

In case of ambient conditions deviating from normal conditions, e.g.high ambient

temperatures, high relative humidity, aggressive ambient media, the intervals between changes

should be shorter. In such cases, contact Technical Support for assistance in determining the

individual lubricant change interval.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 521

Loading...

Loading...