9.2 System runtime

By evaluating the system runtime of the converter, you can decide whether you must replace

components subject to wear such as fans, motors and gear units.

Principle of operation

The converter starts the system runtime as soon as the converter is supplied with power. The

system runtime stops when the converter is switched o.

The system runtime comprises r2114[0] (milliseconds) and r2114[1] (days):

System runtime = r2114[1] × days + r2114[0] × milliseconds

If r2114[0] has reached a value of 86,400,000 ms (24 hours), the converter sets the value of

r2114[0] to 0 and increases the value of r2114[1] by 1.

Using system runtime, you can track the chronological sequence of faults and alarms over

time. When a corresponding message is triggered, the converter transfers the parameter

values r2114 to the corresponding parameters of the alarm or fault buer.

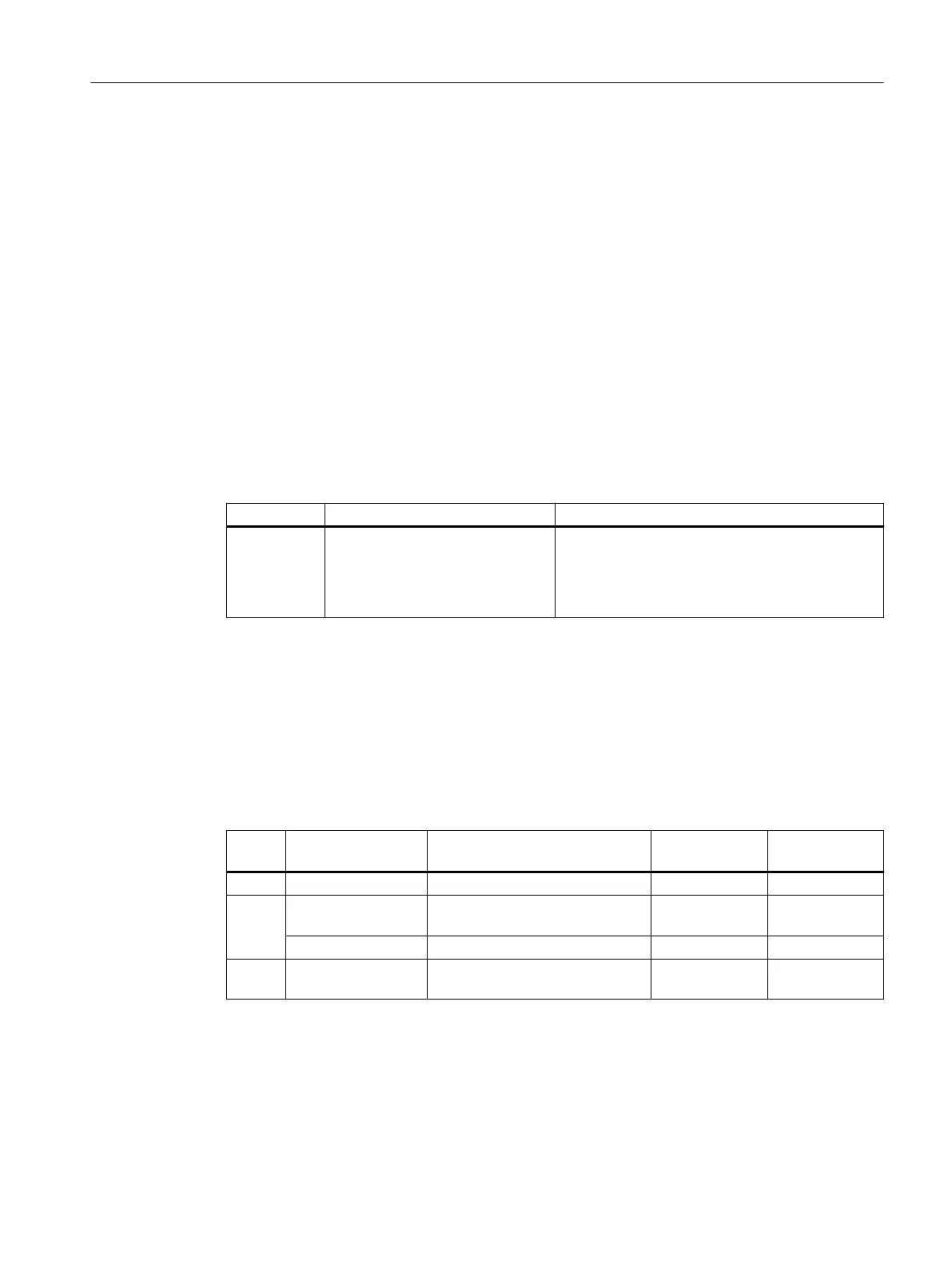

Parameter Description Setting

r2114[0...1] Total system runtime Displays the total system runtime for the drive unit.

Index:

[0]: Milliseconds

[1]: Days

You cannot reset the system runtime.

9.3 Identication & maintenance data (I&M)

I&M data

The converter supports the following identication and maintenance (I&M) data.

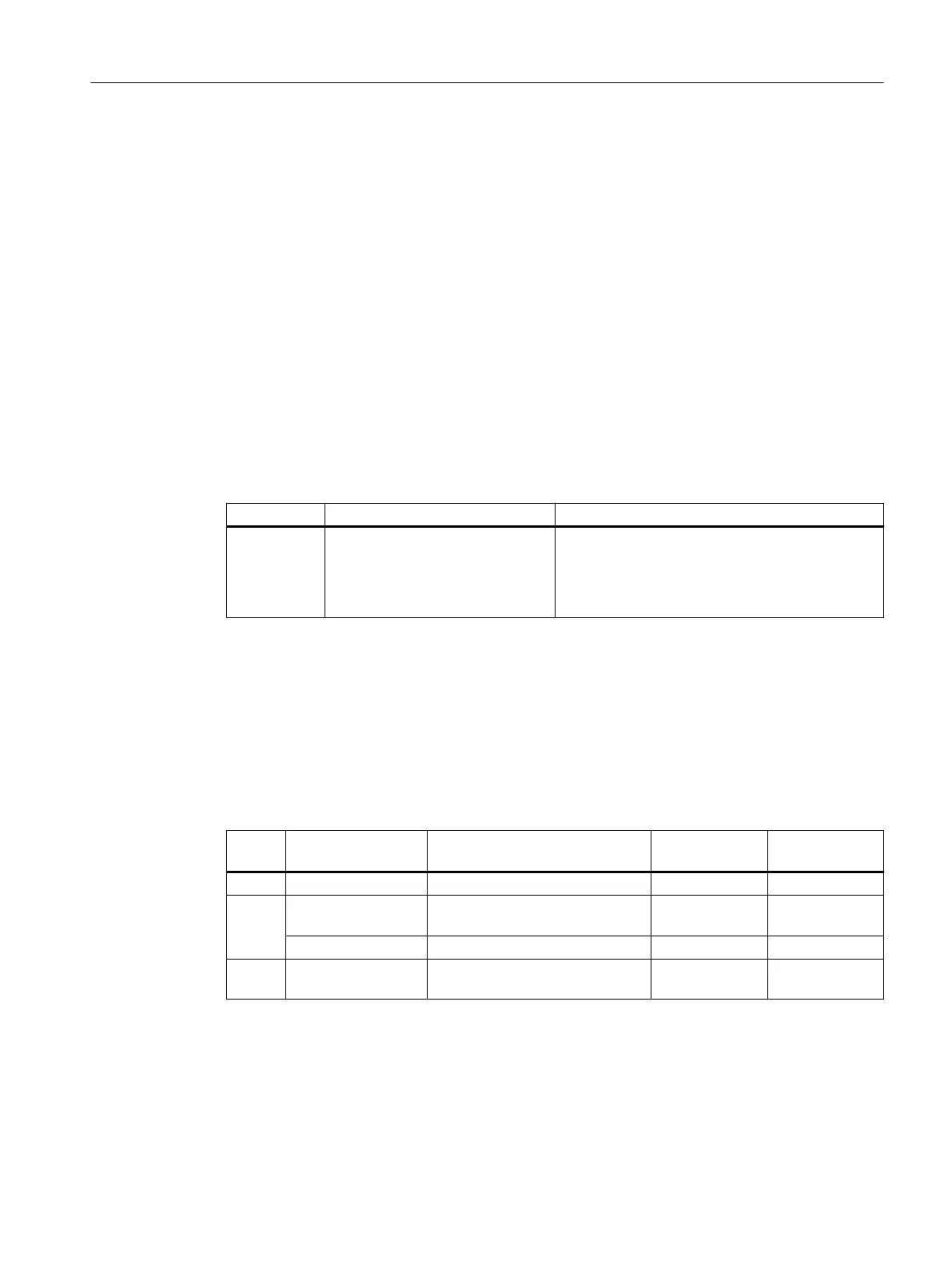

I&M

data

Format Explanation Associated pa‐

rameters

Example for

the content

I&M0 u8[54] PROFINET Converter-specic data, read only - See below

I&M1 Visible String [32] Plant/system identier p8806[0…31] "ak12-

ne.bo2=fu1"

Visible String [22] Location code p8806[32 … 53] "sc2+or45"

I&M2 Visible String [16] Date p8807[0…15] "2013-01-21

16:15"

Alarms, faults and system messages

9.3Identication & maintenance data (I&M)

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 373

Loading...

Loading...