Procedure

1. Push the shrink disk ③ onto the hollow shaft ②.

– 3‑part shrink disk up to the end stop for sizes19‑69.

– 2‑part shrink disk ush with the shaft end for sizes79‑109.

2. Tighten the clamping bolts ⑥, initially by hand. Align the shrink disk ③ so that the clamping

anges are plane-parallel with one other.

3. Use the torque wrench to turn each of the clamping bolts ⑥ equally by 1/6 revolution (not

crosswise); repeat this procedure several times. Observe the tightening torque.

4. Attach the rubber cover or protection cover included in the scope of supply using Removing

and installing the protection cover (Page490).

You have now installed the shrink disk.

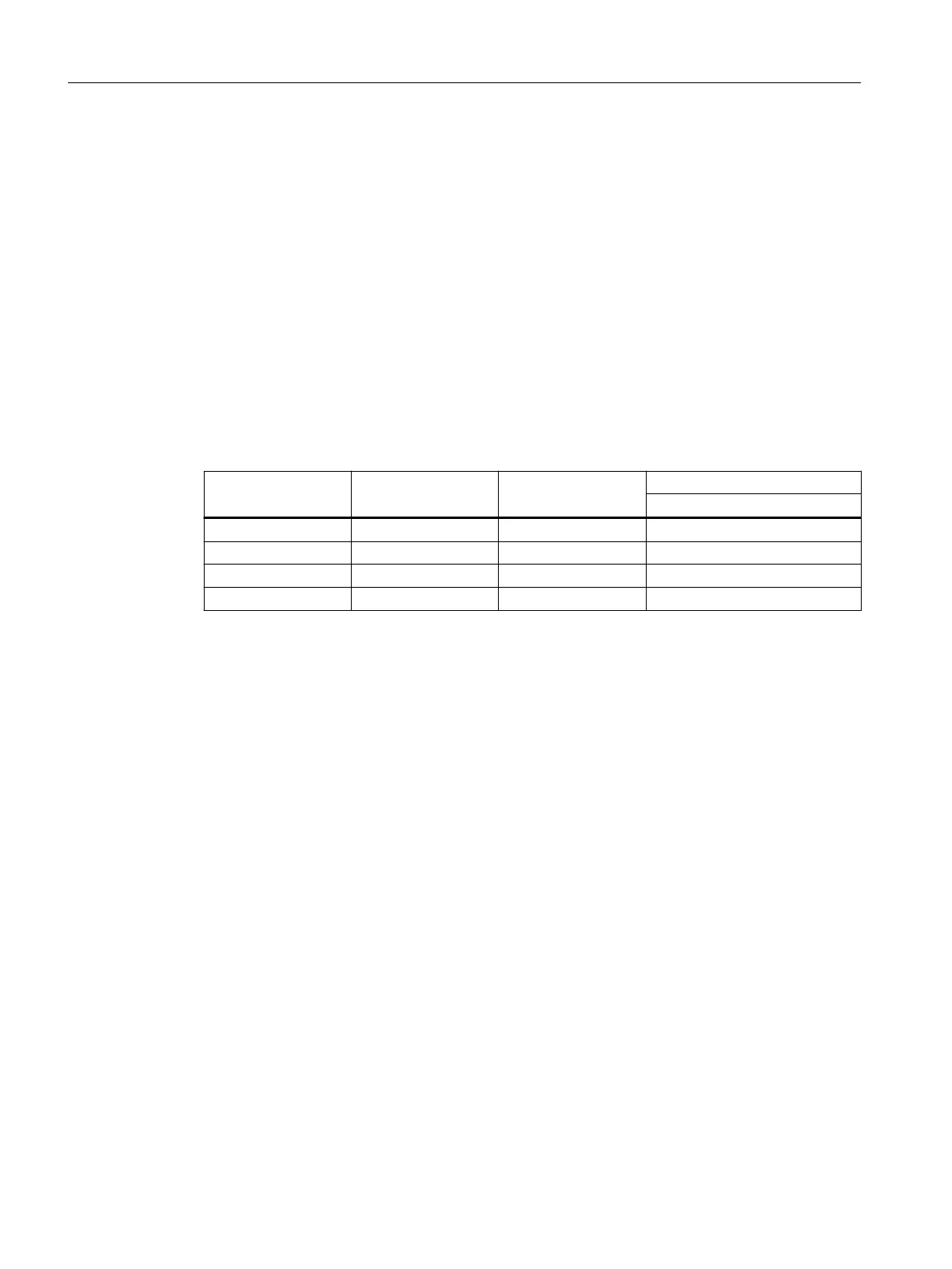

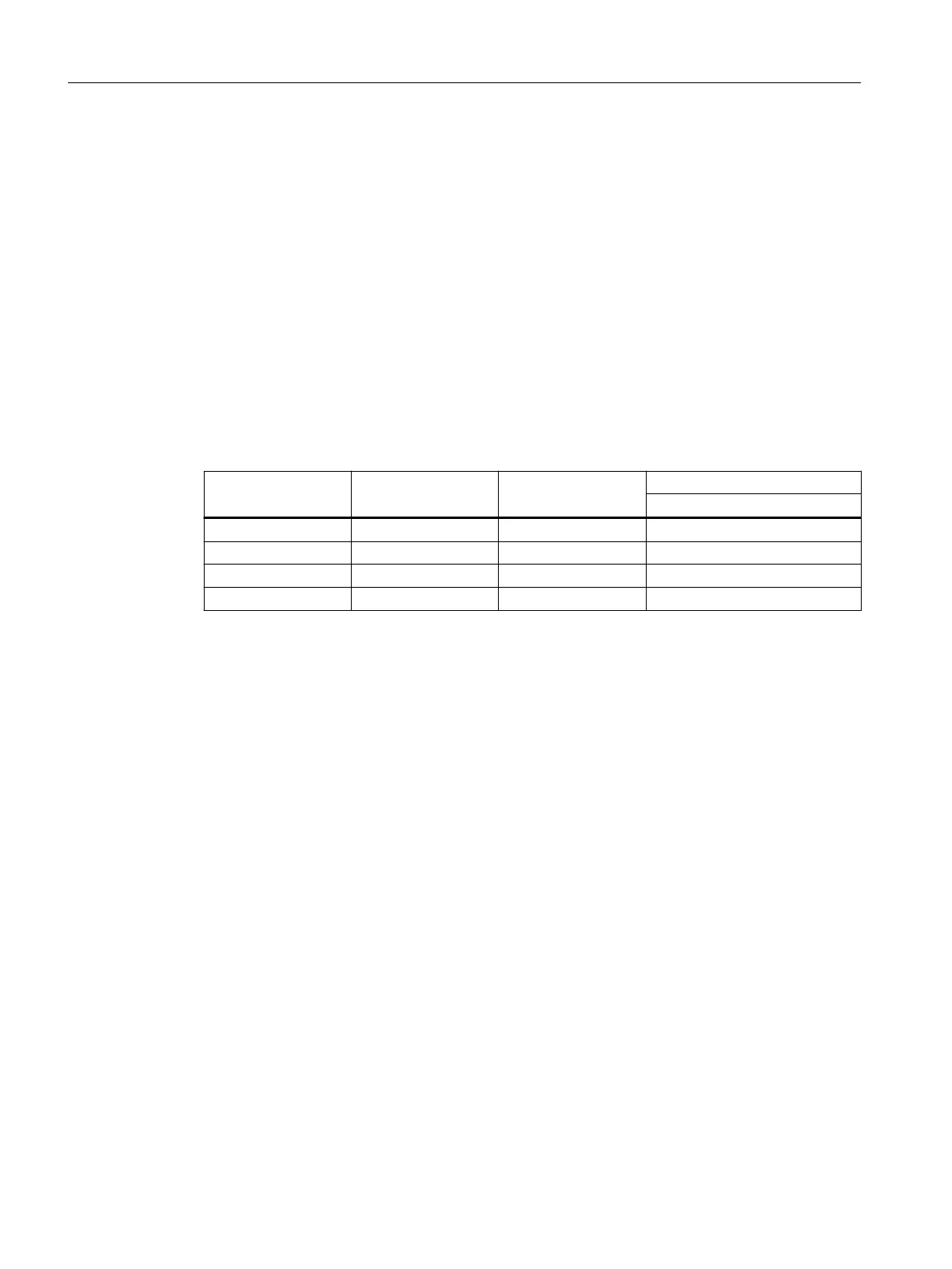

Table 12-35 Tightening torque for the clamping bolt

Gearbox size Thread size Property class Tightening torque

Nm

19, 29 M5 10.9 5

39, 49, 69 M6 10.9 12

79, 89 M8 12.9 35

109 M10 12.9 70

12.3.15.3 Pulling o the shrink disk

Procedure

1. Successively release the clamping bolts⑥ one after the other through a ¼turn each time

using a wrench. Do not completely remove the bolts.

2. Withdraw the shrink disk from the hollow shaft.

Frame sizes79-109:

If the outer ring does not come away from the inner ring, remove some of the clamping bolts

and insert them into neighboring forcing-o threads.

You have withdrawn the shrink disk from the hollow shaft.

12.3.15.4 Cleaning and lubricating shrink disks

Soiled shrink disks must be cleaned and regreased prior to tting.

Shrink disks that have been released need not be disassembled and regreased before being

retensioned.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

498 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...