operating conditions and loading of the brake. The maintenance intervals and maintenance

work for the pneumatic brake are listed in the table.

Table 12-21 Maintenance interval for the brake

Brake Maintenance interval

Operational brake According to service life calculation

Otherwise every six months

After 4000 operating hours at the latest

Holding brake with emergency

stop

Minimum every 2years

After 1million cycles at the latest

Shorter intervals for frequent emergency stops

12.2.20.3 Adjusting the air gap

WARNING

Unintentional starting of the drive unit

Switch o the power supply to the drive unit.

The brake must be in a torque-free condition.

Secure the drive unit to prevent it from being started up unintentionally.

Attach a warning notice to the start switch.

WARNING

Decrease of braking eect due to contamination

Do not allow oil or grease to come into contact with friction surfaces.

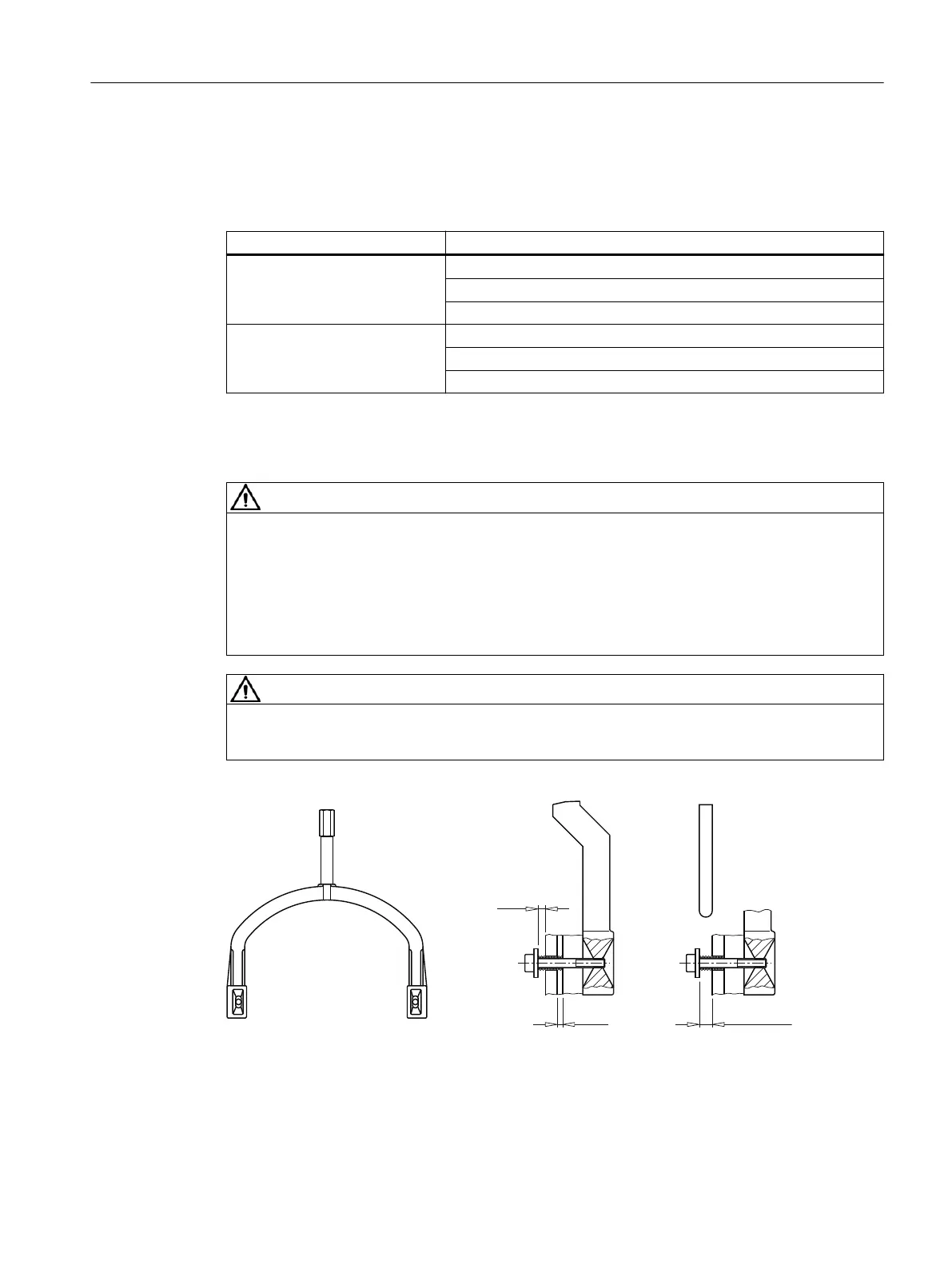

Figure12-10 Setting dimension for air gap

Additional information on the SIMOGEAR geared motor

12.2Specic data motor

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 469

Loading...

Loading...