Procedure

1. Remove the fan cover.

2. Loosen the xing screws of the brake.

3. Screw the sleeve screws further into the solenoid using an open-ended spanner.

4. Tighten the xing screws of the brake.

5. Check the air gaps

LN

in the vicinity of the screws using a feeler gauge.

6. If necessary, correct the air gaps

LN

and then check it again.

7. When combined with manual brake release:

Check the setting dimensions

HL

and corrects

HL

if necessary.

8. Mount the fan cover.

You have now set the air gap.

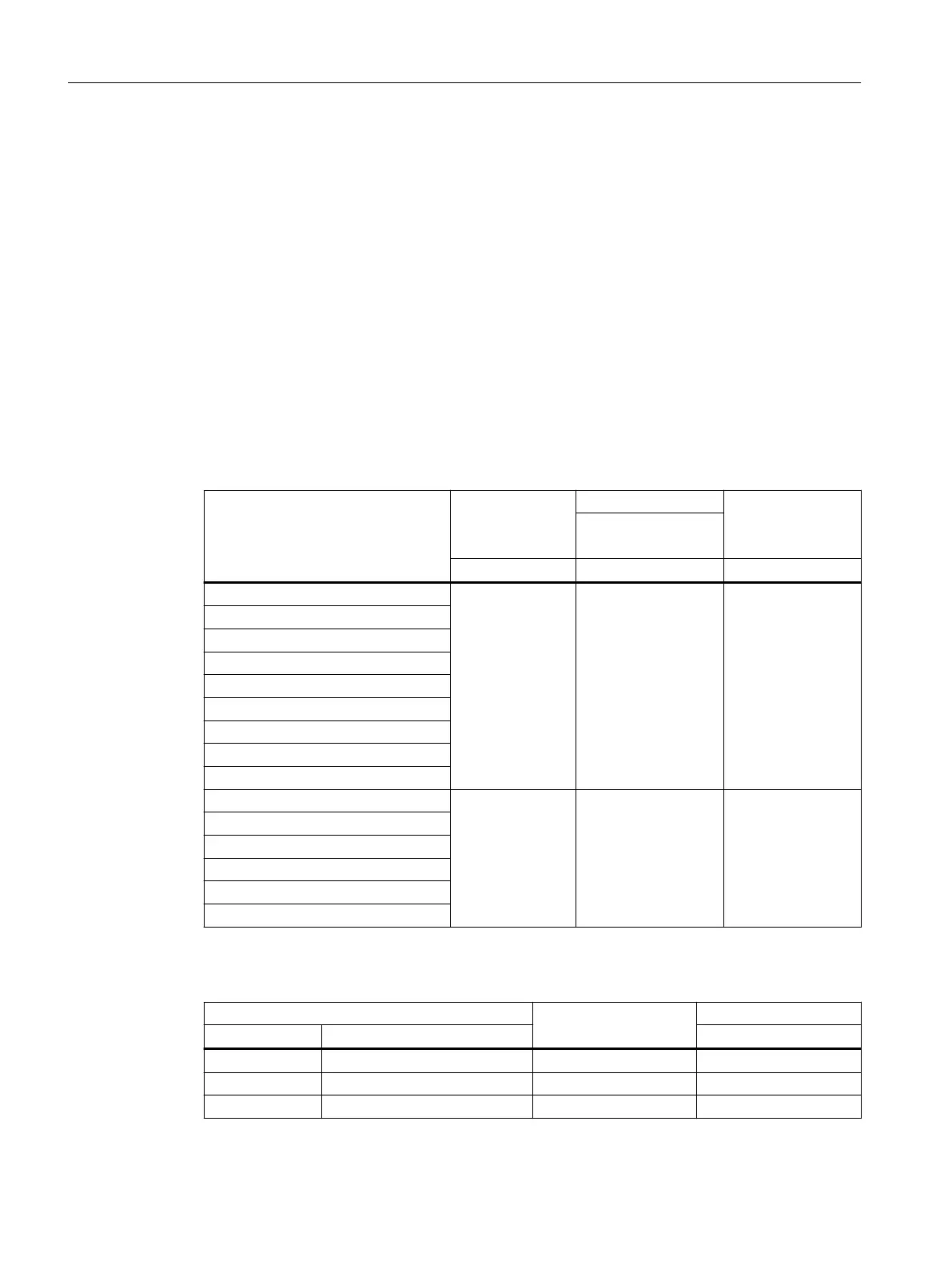

Table 12-22 Air gap values

Brake type Nominal air gap

s

LN

(+0.1/-0.05)

Maximum air gap for Reference gage

s

HL

Standard excitation

s

Lmax.

mm mm mm

L4/1,4 0.2 0.3

1.0

L4/2

L4/3

L4

L8/4

L8/5

L8

L16/8, L16/10, L16/13, L16

L16/20

L32/14, L32/18 0.3 0.45 1.5

L32/23

L32, L60/50

L32/40

L80/25, L80/35, L80/50, L80/63

L80/100

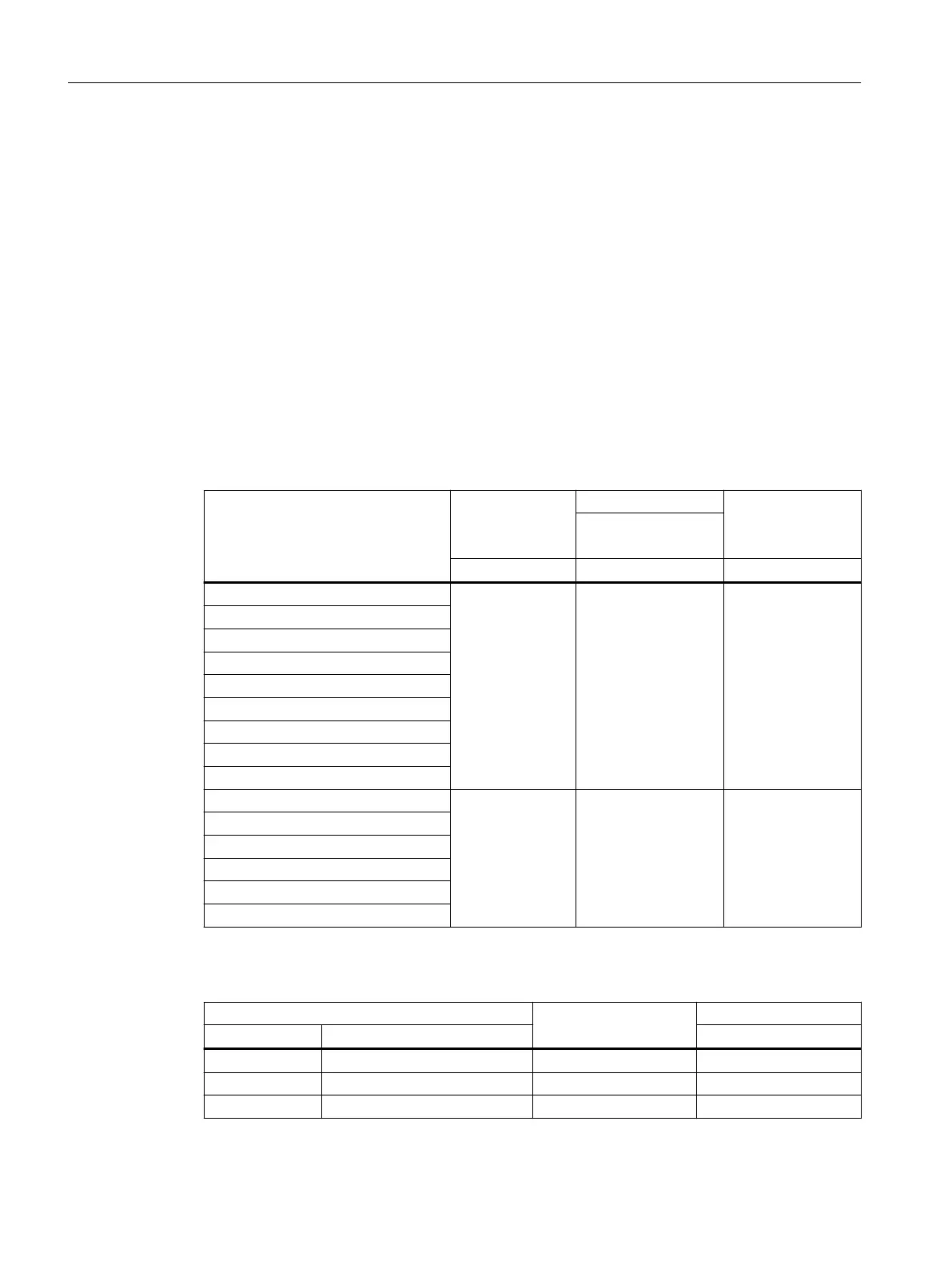

Table 12-23 Tightening torque for the brake screw

Brake type Thread size Tightening torque

Siemens Brake supplier Nm

L4 INTORQBABFK458(06E) 3xM4 3

L8 INTORQBABFK458(08E) 3xM5 6

L16 INTORQBABFK458(10E) 3xM6 10

Additional information on the SIMOGEAR geared motor

12.2Specic data motor

SINAMICS G115D Wall Mounted distributed drive

470 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...