Procedure

1. Switch o the power supply to the drive unit.

2. Unscrew the oil level screw, see Mounting positions (Page 527). Oil escapes if the maximum

ll level is above the plug hole.

3. Check the oil level. Observe the ll levelx.

4. Top up the oil level if necessary and check it again.

5. Check the state of the sealing ring on the sealing element. If the sealing ring is damaged,

replace the sealing element with a new one.

6. After checking, seal the gearbox immediately using the sealing element.

You have now checked the oil level in the gearbox housing.

12.3.24.3 Checking the oil level using the oil sight glass (optional)

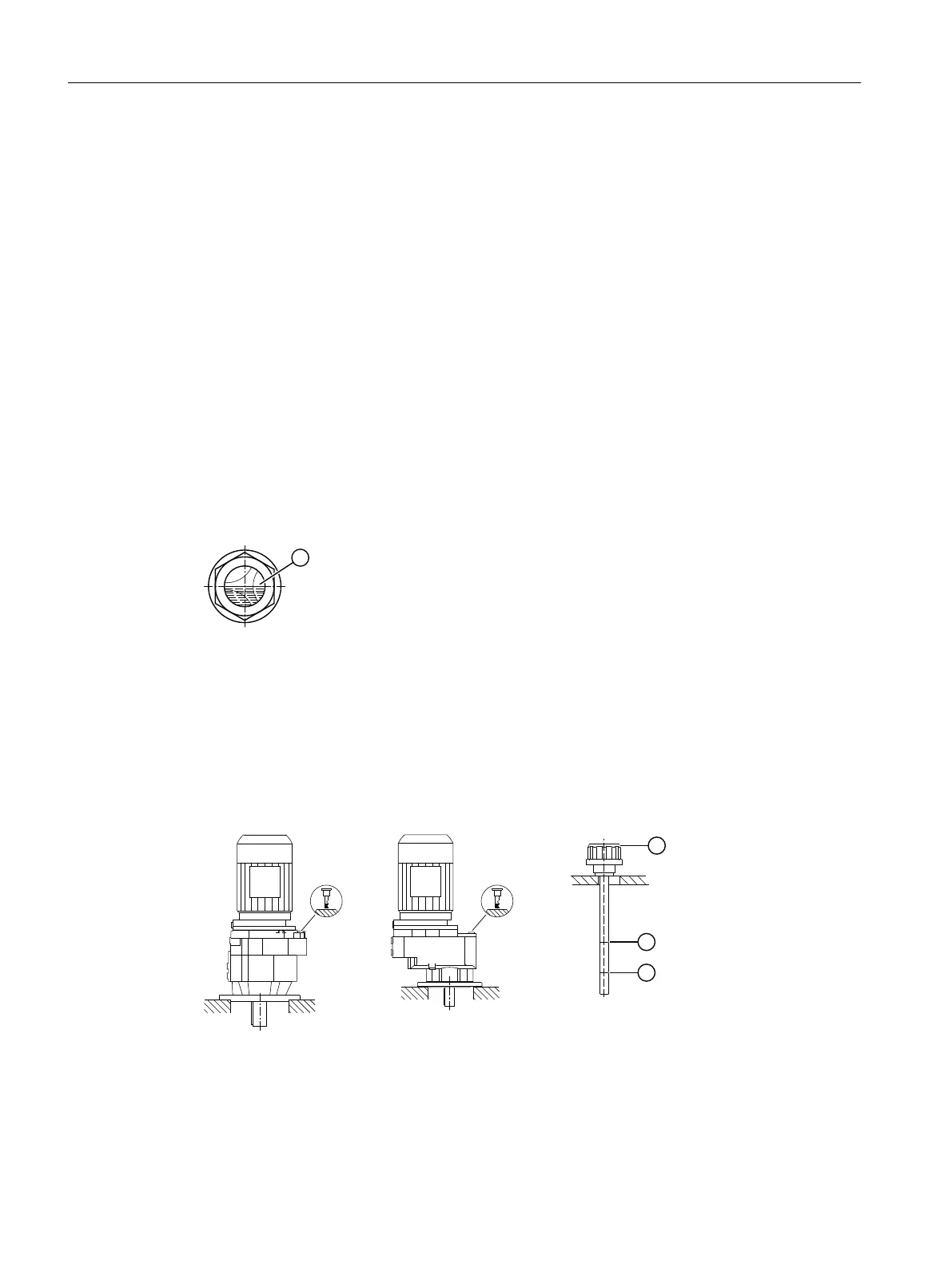

If there is an oil sight glass to check the oil level①, the oil must be visible in the center of the

sight glass when the oil is cool. When the oil is hot, the oil level ① is above the center of the sight

glass. The oil level① of cold oil is below the center of the sight glass.

Figure12-33 Oil level in the oil sight glass

Top up the oil level① if necessary, and check it again.

12.3.24.4 Checking the oil level using the oil dipstick (optional)

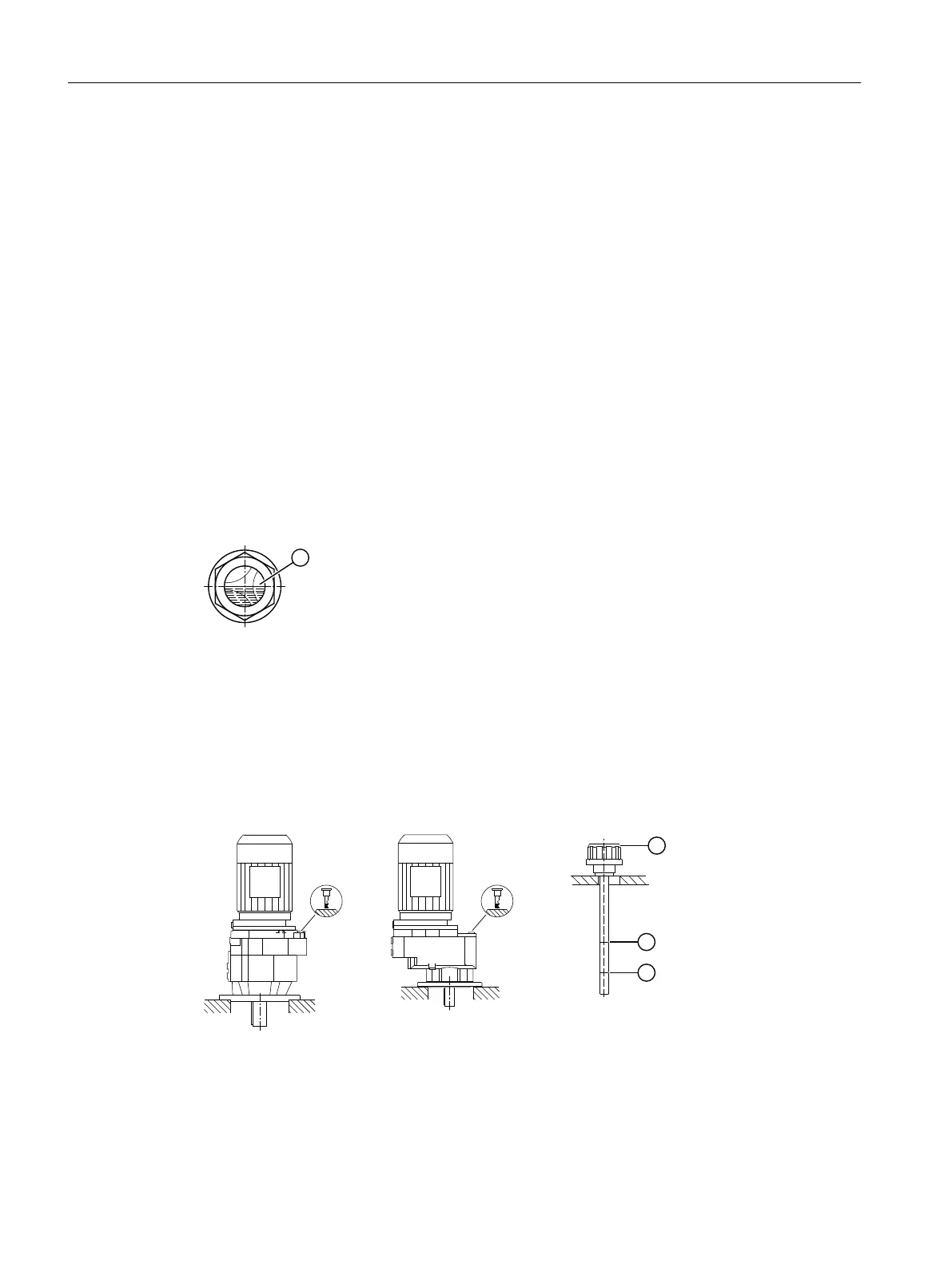

In the M4 mounting position for ZF/EF helical gearboxes, the oil level can be checked with an oil

dipstick.

Figure12-34 Checking the oil level using the oil dipstick

To check the oil level, push the oil dipstick① into the hole but do not screw it in.

The oil level must be between the lower② and upper③ marks on the oil dipstick①.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

516 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...