12.2.10.6 External grounding

Ensure the following when making connections:

• The connecting surface must be bare. Protect the surface against corrosion with a suitable

substance, e.g.acid-free Vaseline.

• Insert the cable lug between the contact bracket and the grounding bracket. Do not remove

the contact bracket which is pressed into the housing.

• Place the spring washer under the screw head.

• Observe the tightening torque for the locking screw, see Mounting and installation (Wall

Mounted) (Page457).

Refer to chapterAUTOHOTSPOT.

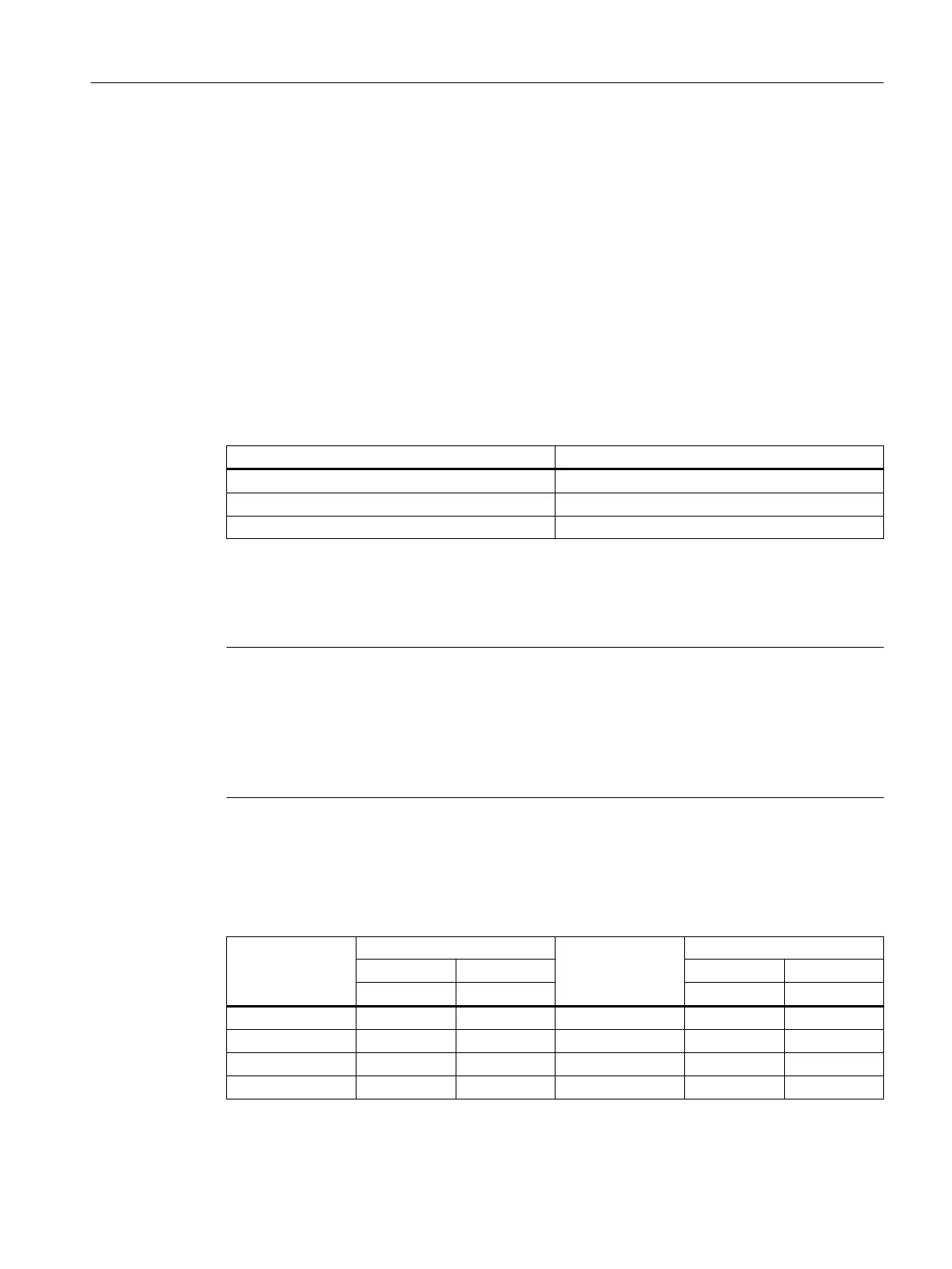

Table 12-12 Maximum conductor connection for external grounding

Motor frame size Thread size

71…90 M4

100…112 M5

132 M6

12.2.10.7 Mounting and installation (Wall Mounted)

See previous sections for the motor-mounted converter.

Note

Match the gland to the connecting cable used:

• Seal insert

• Armor

• Braiding

• Shielding

Screw the gland into the housing. Or secure the gland using a locknut.

Terminal board connection

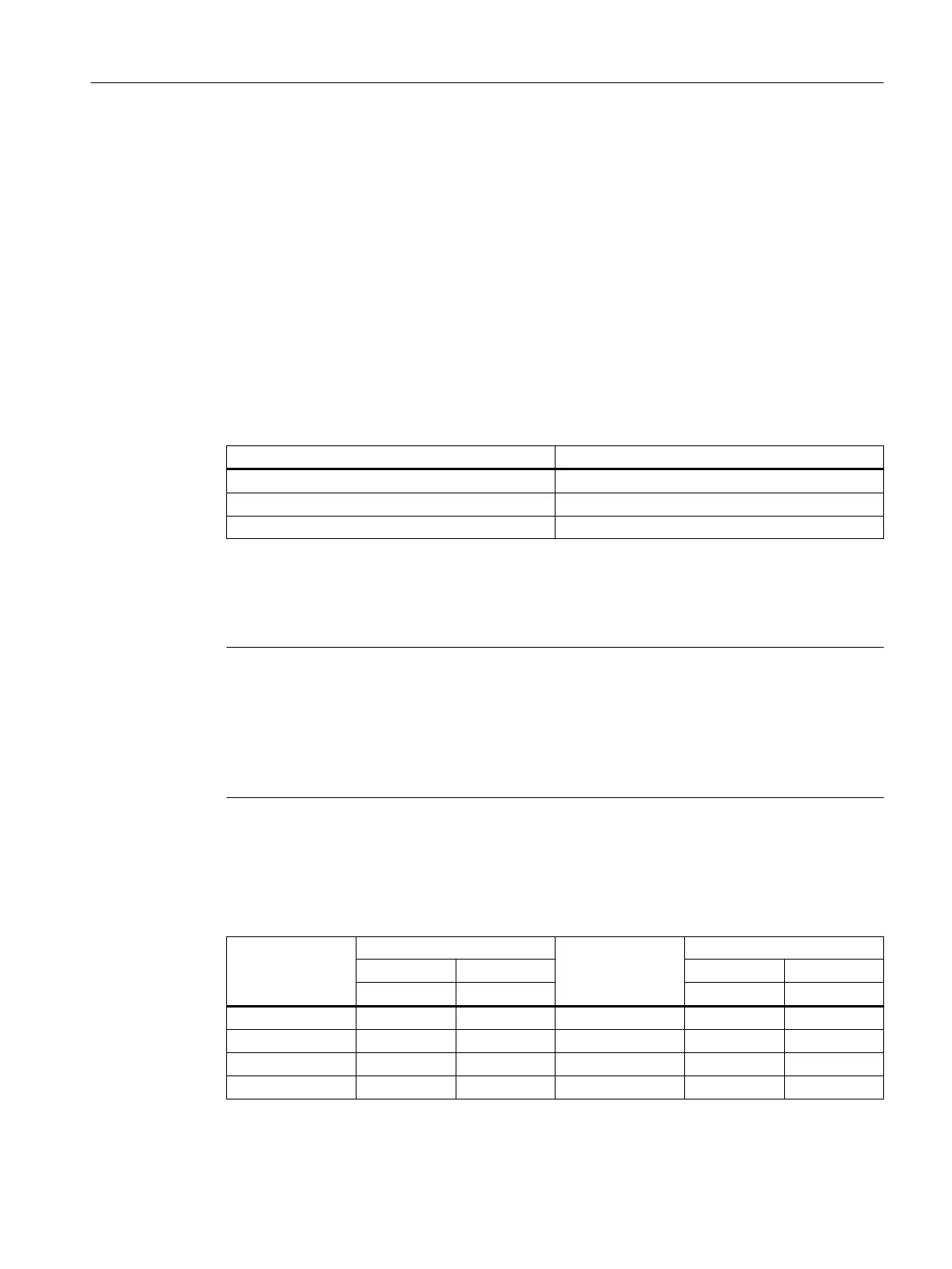

Table 12-13 Tightening torque for the terminal board connection

Thread size Tightening torque Thread size Tightening torque

Min. Max. Min. Max.

Nm Nm Nm Nm

M4 0.8 1.2 M10 9 13

M5 1.8 2.5 M12 14 20

M6 2.7 4 M16 27 40

M8 5.5 8 ‑ ‑ ‑

Additional information on the SIMOGEAR geared motor

12.2Specic data motor

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 457

Loading...

Loading...