12.3.26 Checking the gearbox for leaks

Note

Due to the inherent principle of operation, oil mist can escape from a breather valve or labyrinth

seal.

Oil or grease escaping in small quantities from the shaft sealing ring should be regarded as

normal during the running-in phase of 24hours operating time.

If the quantities escaping are signicant or leaking continues after the running-in phase, the

shaft sealing ring must be replaced to prevent consequential damage.

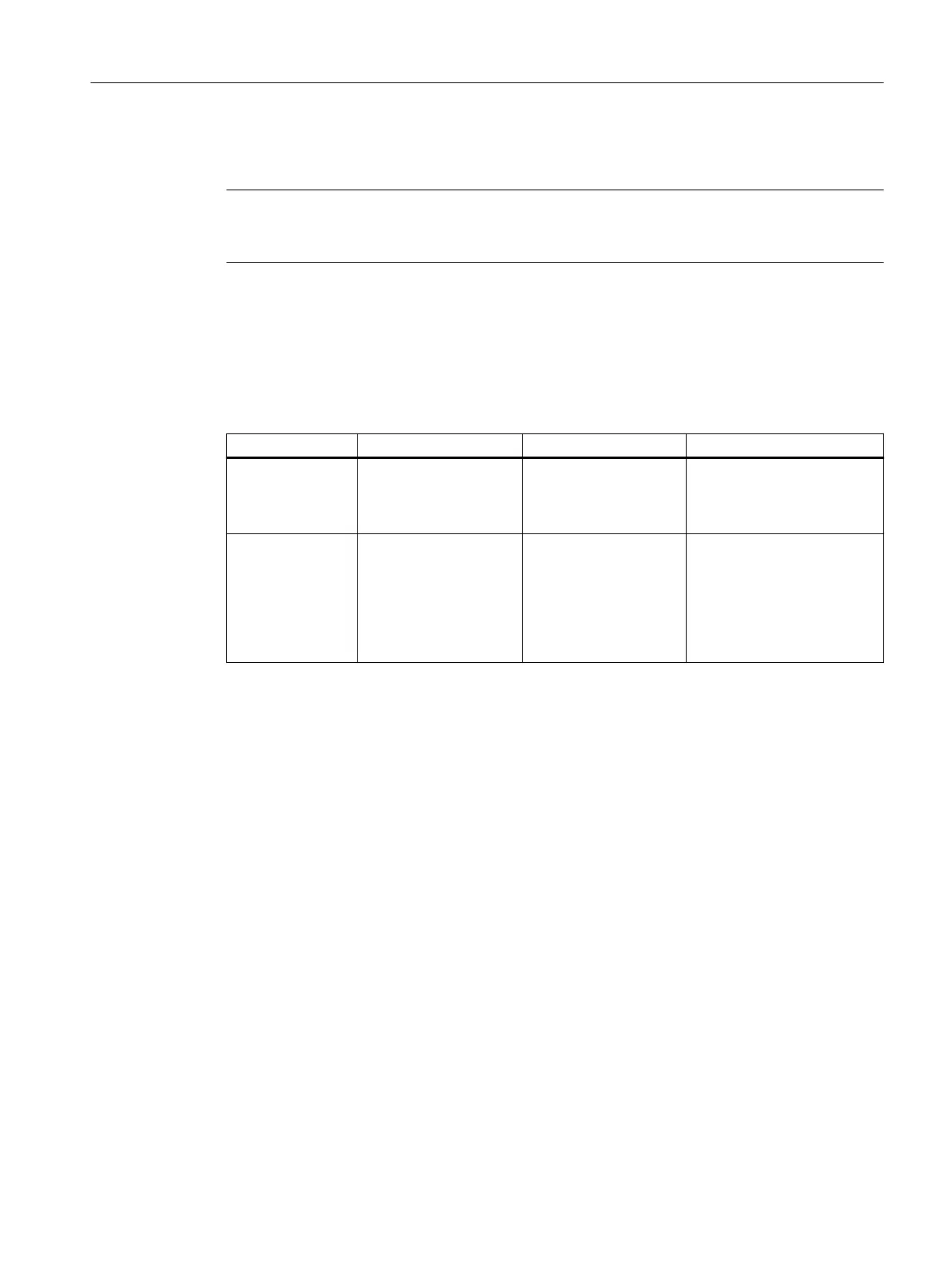

Table 12-47 Description and measures

Status Description Measures Notes

Film of moisture

on the shaft seal‐

ing ring

Film of moisture as a re‐

sult of the inherent prin‐

ciple of operation (appa‐

rent leakage)

Remove using a clean

cloth and continue to

observe.

This does not represent a

fault; frequently, in the

course of operation, the seal‐

ing ring dries o.

Leakage at the

shaft sealing ring

Identiable small trickle,

formation of drops, also

after the running-in

phase

Replace the sealing ring,

determine the possible

cause of the sealing ring

failure and rectify.

During the run-in period, the

shaft sealing ring beds into

the shaft. A visible track can

be seen on the shaft. Opti‐

mum preconditions for a per‐

fect seal are obtained after

the run-in period.

12.3.27 Replacing the vent valve

To ensure correct functioning, renew the breather valve yearly.

When replacing, prevent dirt and damaging atmospheres from entering the gearbox.

If too much oil is contained in the gearbox, oil will escape from the breather valve. Correct

the oil quantity and replace the breather valve.

12.3.28 Checking the oil level sensor (optional)

The oil level sensor indicates the oil level only when the gearbox is shut down.

Lower the oil level and ll it up again until the oil level sensor gives a switching signal.

Please refer to the separate operating instructions for the oil level sensor.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 525

Loading...

Loading...