12.3.29 Checking the tightness of fastening bolts

Note

Replace damaged headless bolts with new bolts of the same type and strength class.

Switch o the power supply to the drive unit. Check all fastening bolts for tightness using a

torque wrench.

The general tolerance for the tightening torque in Nm is 10 %. The friction coecient is 0.14 μ.

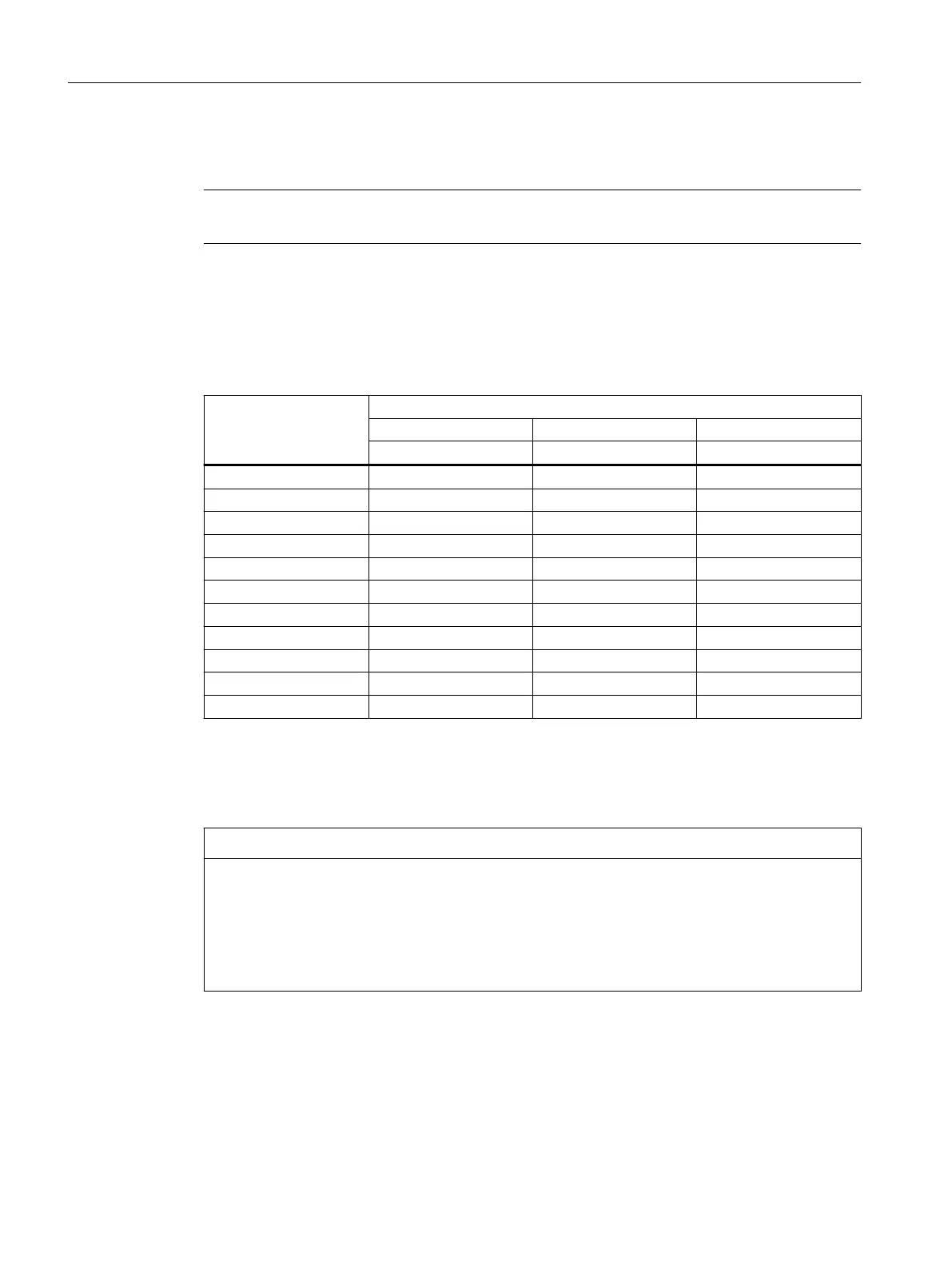

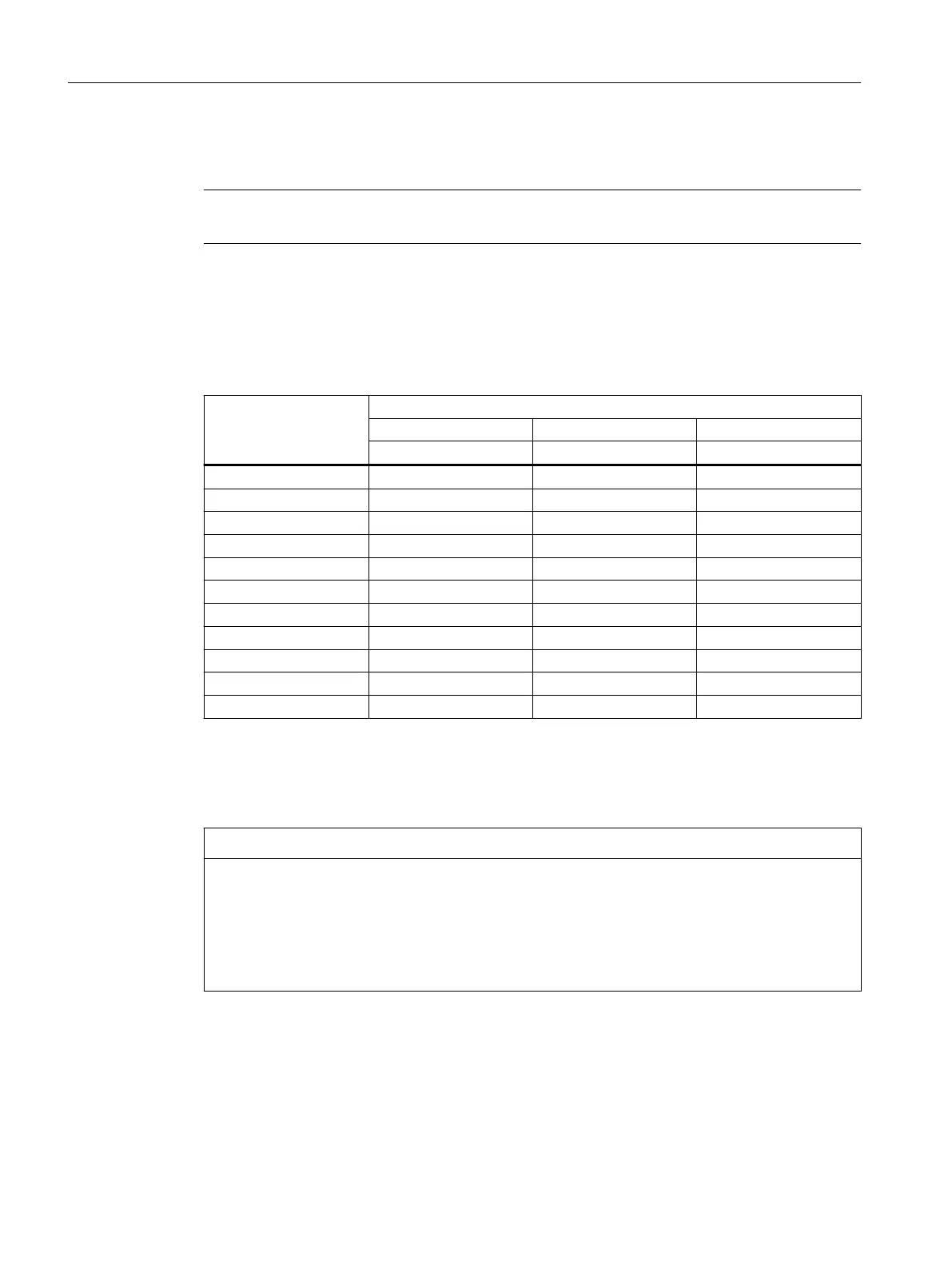

Table 12-48 Tightening torques for fastening bolts

Thread size Tightening torque for strength class

8.8 10.9 12.9

Nm Nm Nm

M4 3 4 5

M5 6 9 10

M6 10 15 18

M8 25 35 41

M10 50 70 85

M12 90 120 145

M16 210 295 355

M20 450 580 690

M24 750 1000 1200

M30 1500 2000 2400

M36 2500 3600 4200

12.3.30 Replacing the hose of the oil expansion unit

NOTICE

Hose with leaks

The hose of the oil expansion unit is subject to natural wear. The service life depends on the

operating conditions.

Check the hose regularly for tears or leaks.

Renew the hose every 4 years at the latest.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

526 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...