A.1.2 Application example

Shift the control logic into the converter

It is only permissible that a conveyor system starts when two signals are present simultaneously.

These could be the following signals, for example:

• The oil pump is running (the required pressure level is not reached, however, until after 5

seconds).

• The protective door is closed.

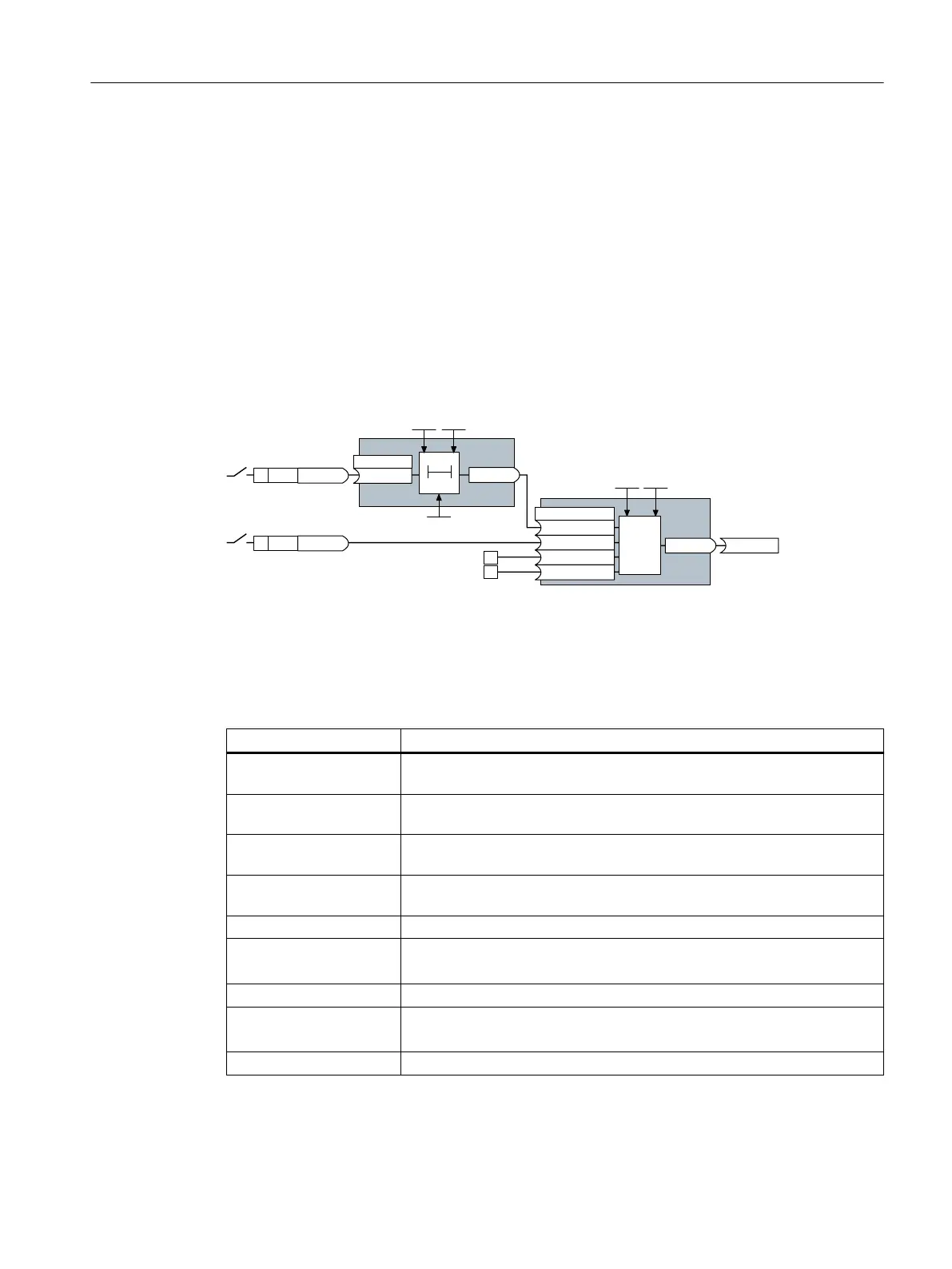

To implement this task, you must insert free function blocks between digital input 0 and the

command to switch on the motor (ON/OFF1).

212))

S S

S>@

U

S >PV@

S

S

7

3'(

S>@

U

U

U

S>@

$1'

',

',

The signal of digital input0 (DI0) is fed through a time block (PDE0) and is interconnected

with the input of a logic block (AND 0). The signal of digital input 1 (DI 1) is interconnected to

the second input of the logic block. The logic block output issues the ON/OFF1 command to

switch on the motor.

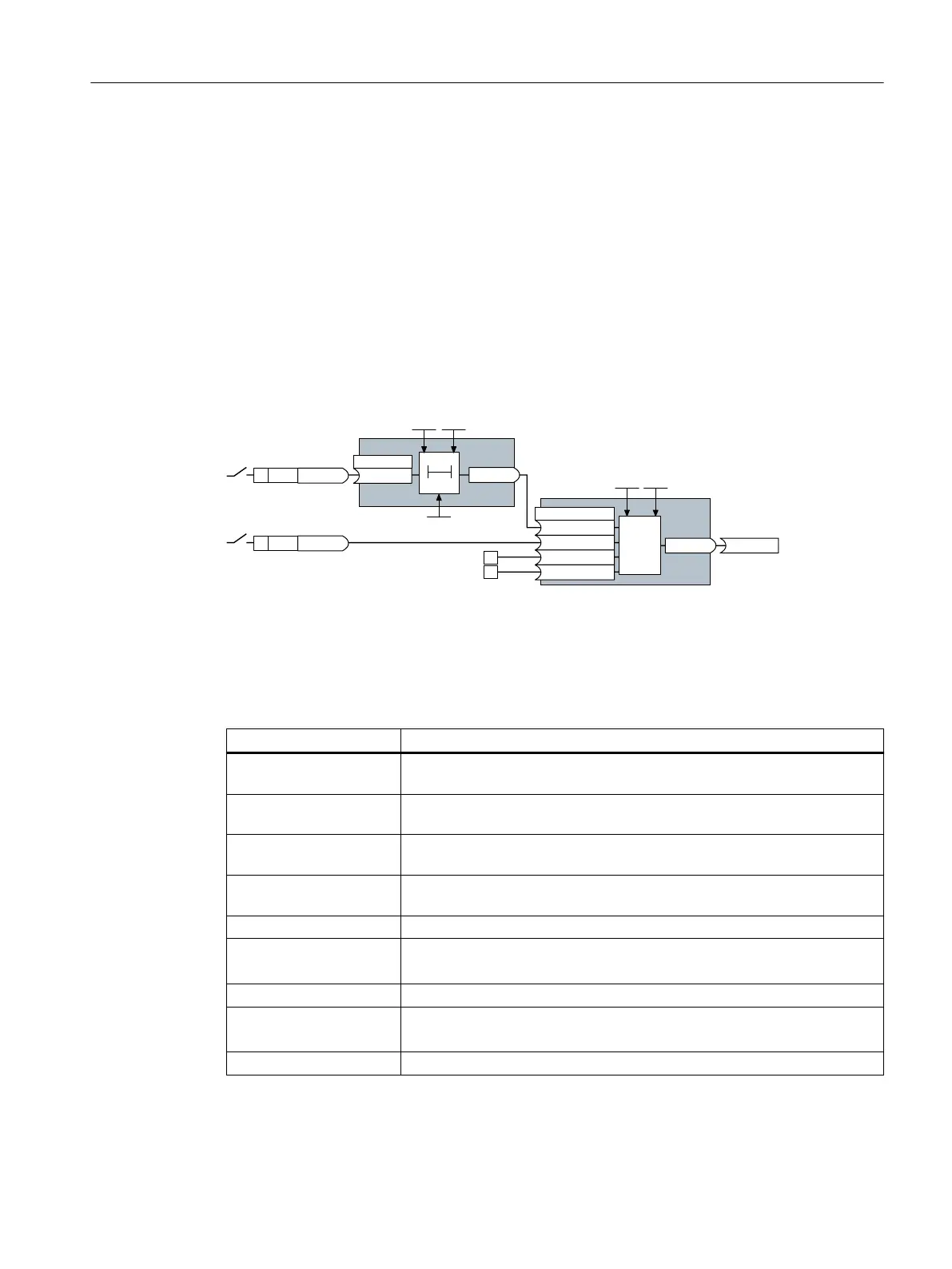

Setting the control logic

Parameter Description

p20161 = 5 The time block is enabled by assigning to runtime group5 (time slice of

128ms)

p20162 = 430 Run sequence of the time block within runtime group 5 (processing before

the AND logic block)

p20032 = 5 The AND logic block is enabled by assigning to runtime group 5 (time slice of

128ms)

p20033 = 440 Run sequence of the AND logic block within runtime group5 (processing

after the time block)

p20159 = 5000.00 Setting the delay time [ms] of the time module: 5 seconds

p20158 = 722.0 Connect the status of DI 0 to the input of the time block

r0722.0 = Parameter that displays the status of digital input 0.

p20030[0] = 20160 Interconnecting the time block to the 1st AND input

p20030[1] = 722.1 Interconnecting the status of DI 1 to the 2nd AND input

r0722.1 = Parameter that displays the status of digital input 1.

p0840 = 20031 Interconnect the AND output to ON/OFF1

Appendix

A.1Interconnecting signals in the converter

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 583

Loading...

Loading...