5. Replace the nut ③ and the threaded spindle ④ with a screw ⑨. Tighten the bolts ⑨ to the

specied torque.

6. Close the open hollow shaft end using a sealing cap⑩.

You have now mounted the hollow shaft with parallel key.

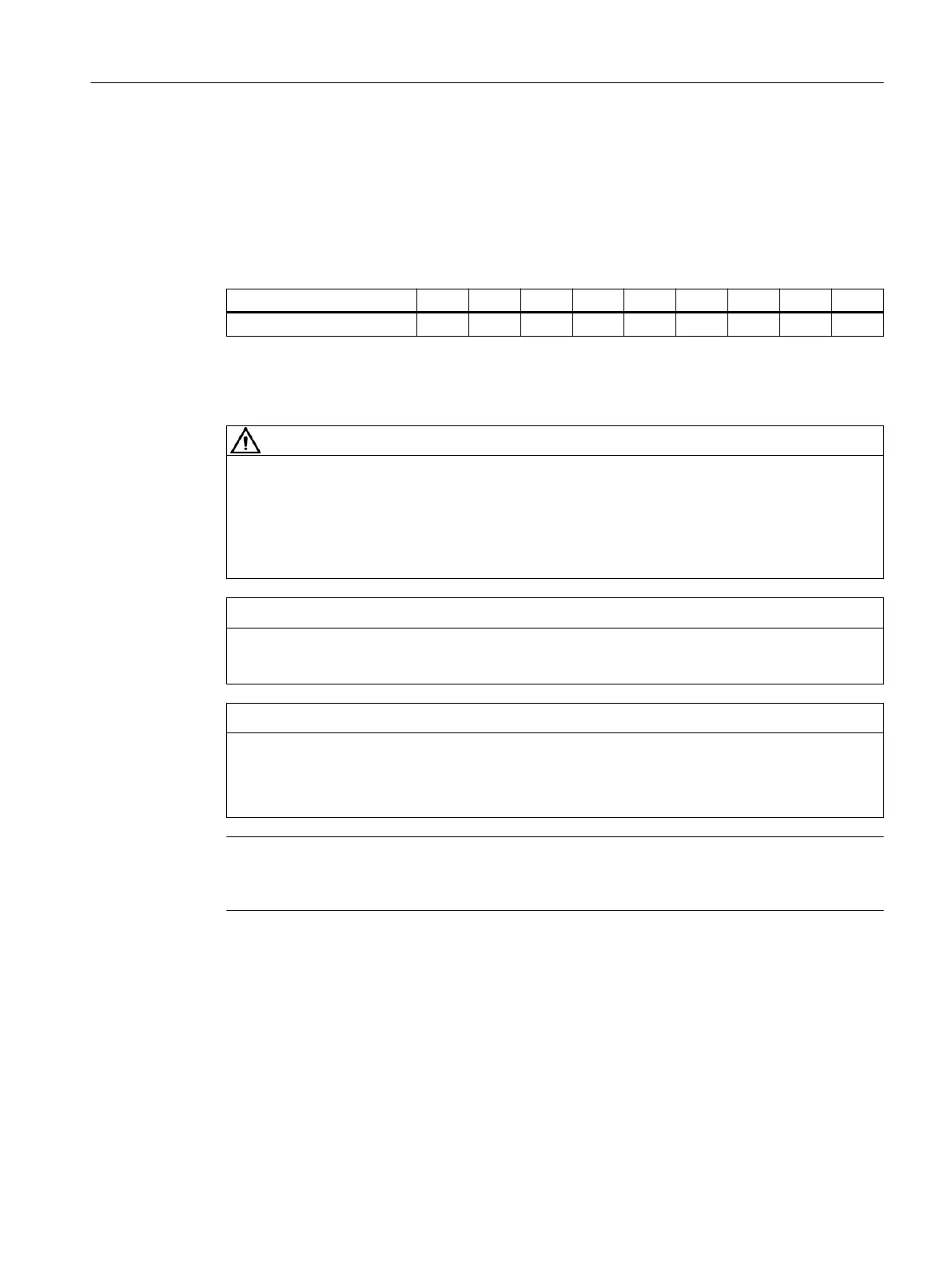

Table 12-34 Tightening torque for the screw

Thread size M5 M6 M8 M10 M12 M16 M20 M24 M30

Tightening torque in Nm 5 8 8 14 24 60 120 200 400

12.3.14.2 Removing the hollow shaft with parallel key

WARNING

Inadequately fastened gearboxes or geared motors can break loose

Before driving out the machine shaft, fasten a suitably dimensioned means of absorbing load

to the gearbox.

Slightly pretension the pulling equipment so that the gearbox does not drop onto it when the

plug-in shaft is released.

NOTICE

Subjecting stress to the hollow shaft causes bearing failure

Avoid misalignment when removing the unit.

NOTICE

Excessive forces during removal

Excessive forces can occur during removal of the hollow shaft via the housing.

Stresses in the hollow shaft can lead to bearing failure and damage to the gearbox housing.

Note

If frictional corrosion has occurred on the seat surfaces, use rust solvent to facilitate the removal

of the gearbox. Allow an adequately long time for the rust solvent to take eect.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 493

Loading...

Loading...