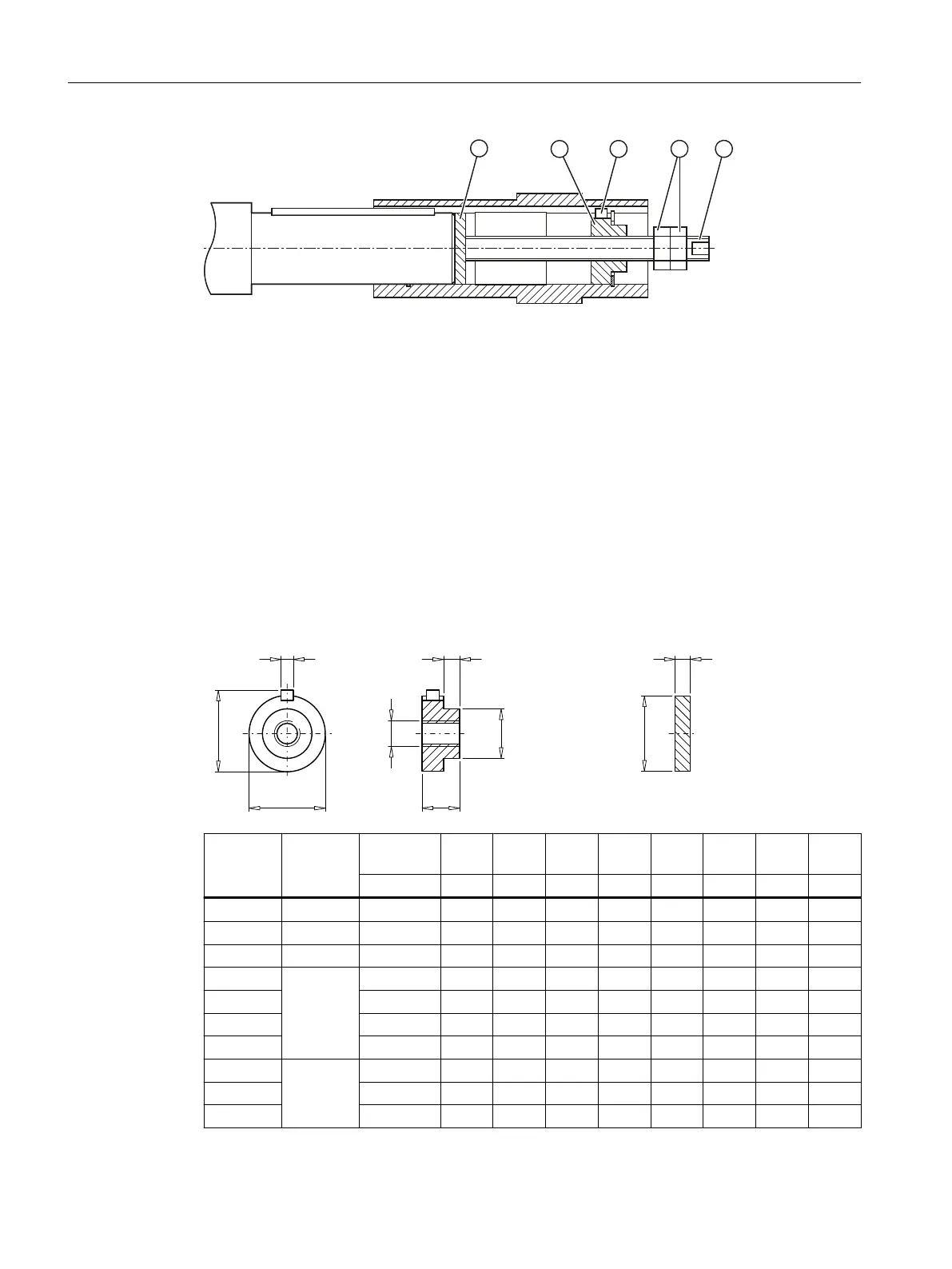

Items①to⑤ are not included in the scope of supply.

① Disk ④ Hexagon nut

② Threaded block ⑤ Threaded spindle

③ Parallel key

Figure12-21 Removing the hollow shaft with parallel key

Procedure

1. Remove the axial locking element from the hollow shaft.

2. Drive out the machine shaft using the disk ①, threaded block ②, parallel key ③, threaded

spindle⑤ and hexagon nuts④.

You have now removed the hollow shaft with parallel key.

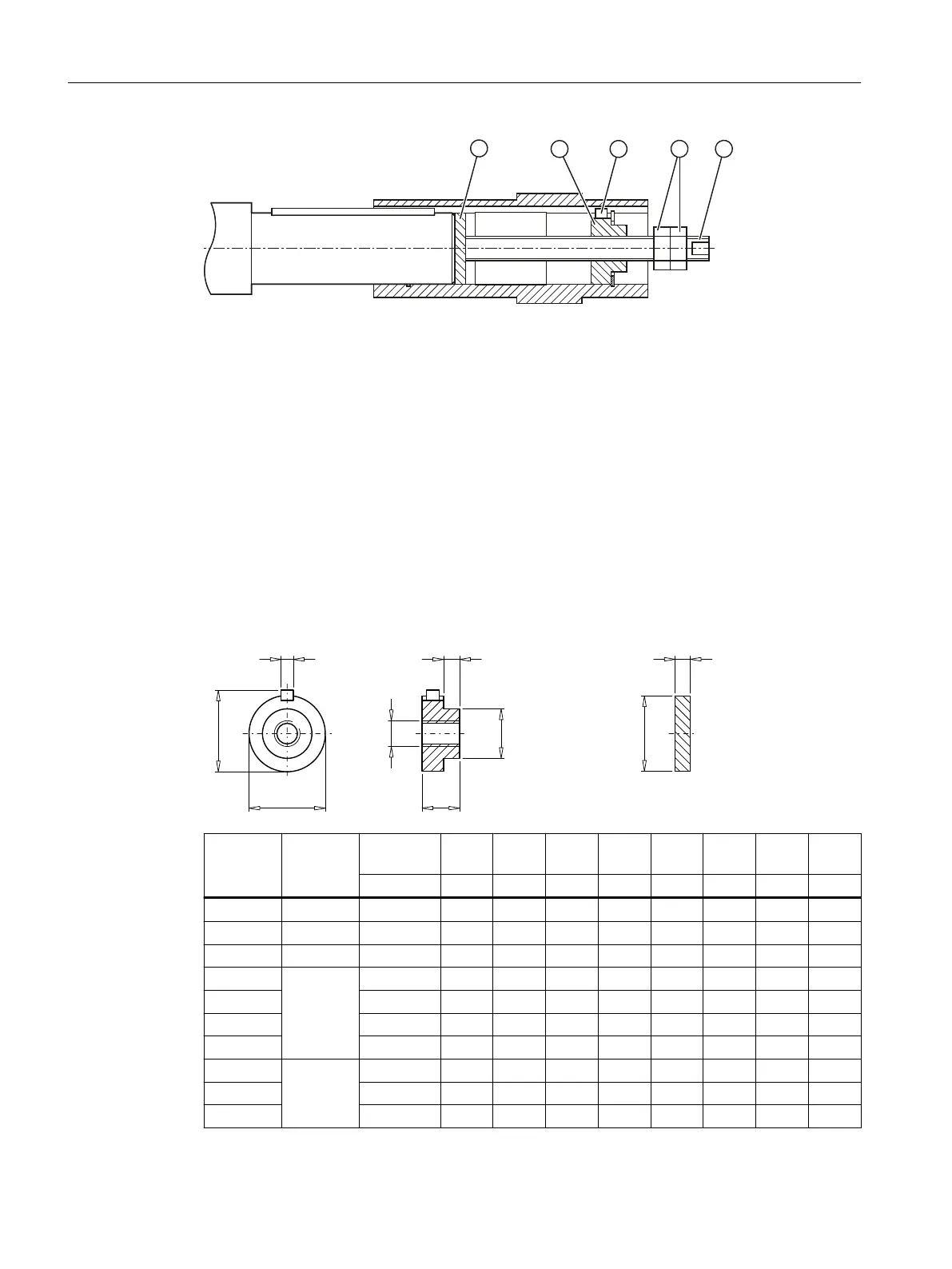

Design suggestion for threaded block and disk

G

V

G

E

G

E

E

X

W

Gearbox Size Hollow

shaft ∅

b10 b11 b12 d10 d11 s11 t

max

u

mm mm mm mm mm mm mm mm mm

B 19 20 3 15 10 19.9 10 M6 22.5 6

B, C 29 20 3 15 10 19.9 10 M6 22.5 6

B, F 29 25 3 15 10 24.9 16 M10 28 8

C 39 25 3 15 10 24.9 16 M10 28 8

B, K, F, C 30 6 15 10 29.9 18 M10 33 8

B 35 6 15 10 34.9 24 M12 38 10

B 40 6 15 10 39.9 28 M16 43 12

C 49 30 6 15 10 29.9 18 M10 33 8

K, F, C 35 6 15 10 34.9 24 M12 38 10

B 40 6 15 10 39.9 28 M16 43 12

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

494 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...