If, following agreement, the gearbox is lled at the factory with special lubricant for the

applications listed above, the lubricant is shown on the rating plate.

The oil quality must meet the gearbox lubricant requirements specied in the NT7300 table.

The Siemens warranty is otherwise null and void. We recommend the use of one of these

gearbox lubricants. These gearbox oils are subject to constant testing and meet the specied

requirements. It is possible that the recommended oils are deleted or replaced by oils that

have been further developed at a later point in time. We recommend that you regularly

check as to whether the selected lubricating oil is still recommended by Siemens. Otherwise

change the product.

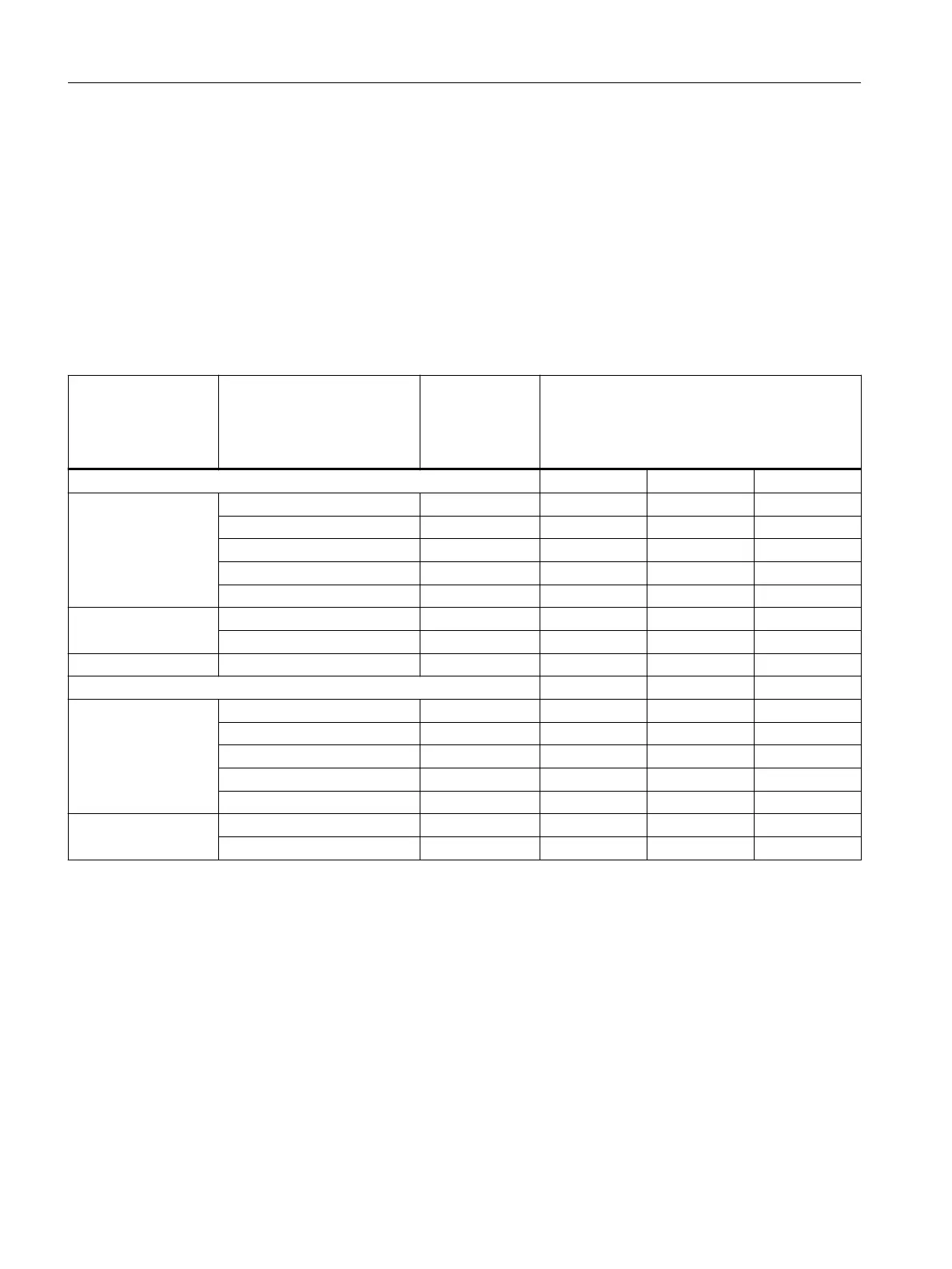

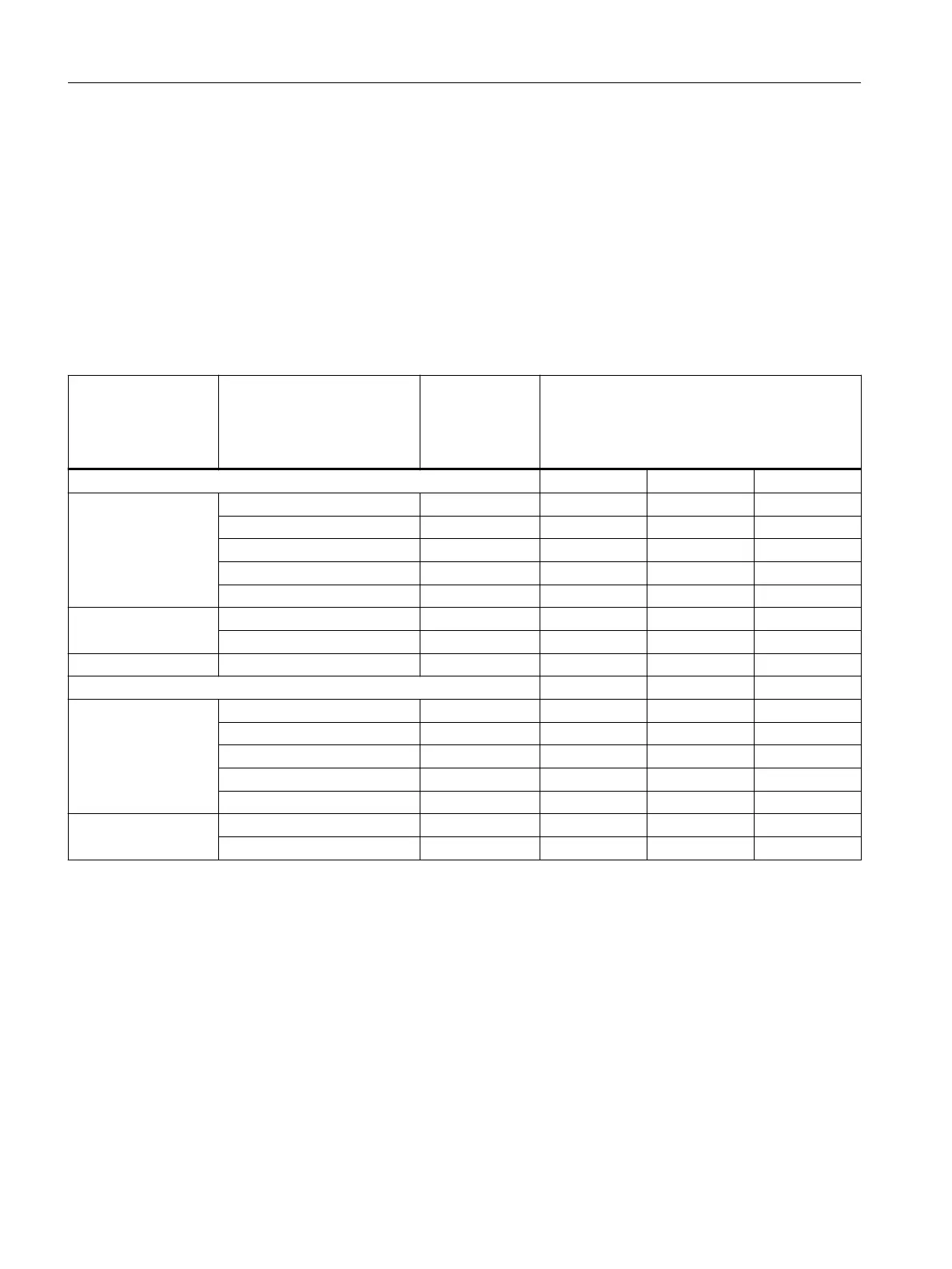

Table 12-46 Lubricant table

Operating range Oil grade

designation according to

DIN51502

Permissible oil

sump tempera‐

ture range dur‐

ing operation

°C

Ambient temperature

°C

Helical gearbox E/Z/D, parallel shaft gearbox F and bevel gearbox K -15...+40° -30...+40° -20...+55

Standard CLPISOVG220 -15...+80° ✓ - -

CLPISOPAOVG220 -30...+100° ✓ ✓ ✓

CLPISOPAOVG68 -40...+60° - ✓ -

CLPISOPGVG460 -25...+110° ✓ - ✓

CLPISOPGVG220 -25...+110° ✓ - ✓

Food sector (USDA)

NSF-H1

CLPISOH1VG460 -25...+100° ✓ - ✓

CLPISOH1VG100 -30...+90° ✓ ✓ ✓

Biodegradable oil CLPISOEVG220 -20...+100° ✓ - ✓

Helical worm gearbox C, bevel gearbox B -20...+40° -30...+40° -20...+55

Standard CLPISOPGVG220 -25...+110° ✓ - ✓

CLPISOPAOVG460 -25...+110° ✓ - ✓

CLPISOPAOVG220 -30...+100° ✓ ✓ ✓

CLPISOPAOVG68 -40...+60° - ✓ -

CLPISOPGVG460 -25...+110° ✓ - ✓

Food sector (USDA)

NSF-H1

CLPISOH1VG460 -25...+100° ✓ - ✓

CLPISOH1VG100 -30...+90° ✓ - ✓

CLP=mineral oil

CLP PG = polyglycol oil

E = ester oil, organic oil (bio oil / risk of water pollution, class WGK1)

PAO = poly-alpha-olen oil

CLPH1=physiologically safe oil (USDA-H1 approval)

12.3.25 Replace bearings

The bearing service life is nite, greatly depends on the operating conditions and therefore

cannot be calculated reliably. In the operating conditions specied by the operator, bearing life

can be calculated. Changes in vibration and noise pattern are an indication that an immediate

bearing replacement is necessary.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

524 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...