Procedure

1. Only grease the inner friction surfaces of the shrink disks. To do this, use a solid lubricant with

a friction coecient of μ=0.04.

2. Use a paste containing MoS

2

to grease the bolts, applying the paste to the thread and

underneath the head.

Clean the shrink disk.

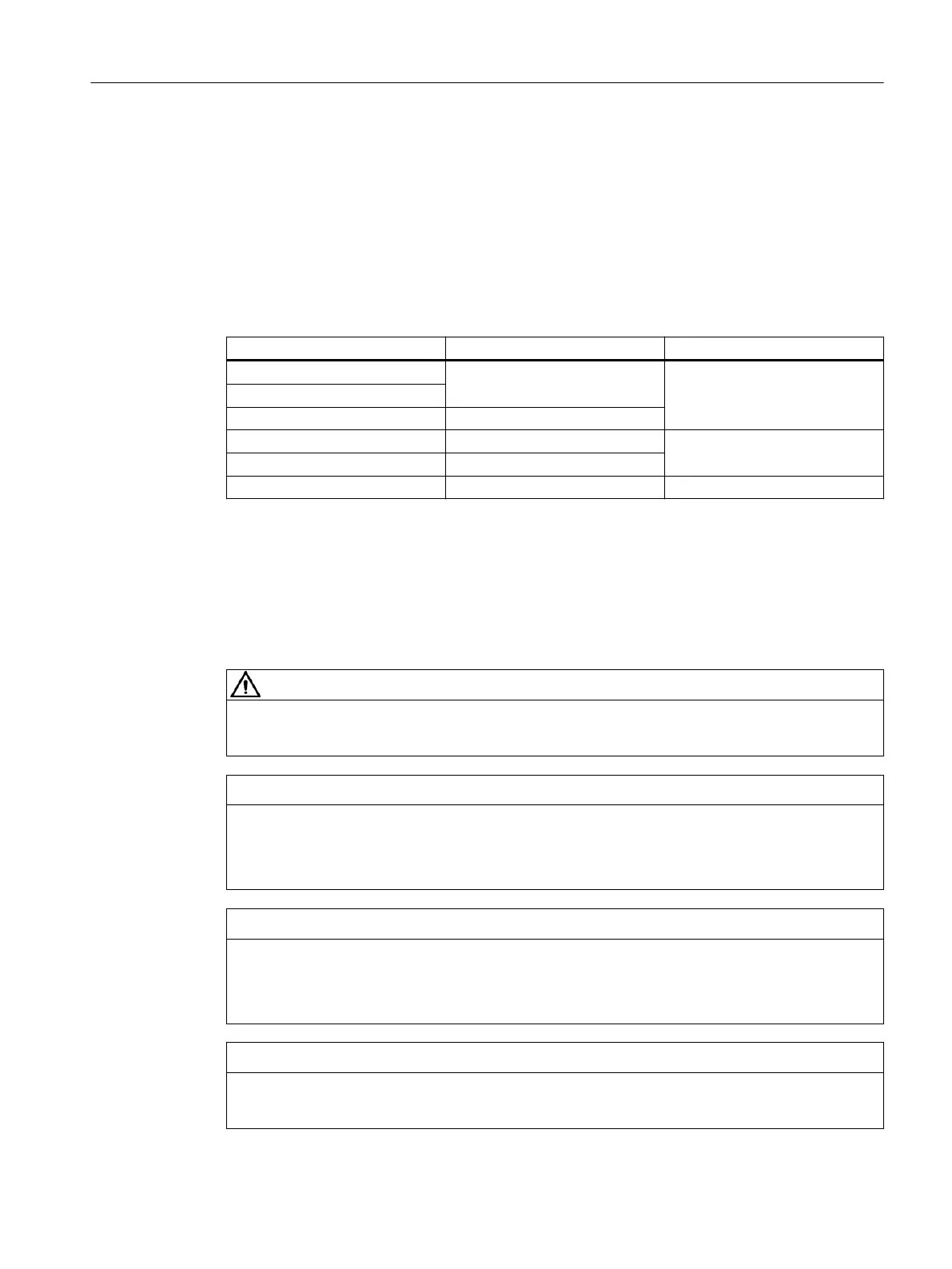

Table 12-36 Lubricants for shrink disks

Lubricant Sold as Manufacturer

Molykote 321 R (lubricant paint) Spray DOW Corning

Molykote spray (powder spray)

Molykote G Rapid Spray or paste

Molykombin UMFT 1 Spray Klüber Lubrication

Unimily P5 Powder

Aemasol MO 19 P Spray or paste A. C. Matthes

12.3.16 SIMOLOC assembly system

12.3.16.1 General notes for the SIMOLOC assembly system

WARNING

Risk of injury due to freely rotating parts

Fit a cover cap or protection cover.

NOTICE

Damaged components impair the correct function of the gearbox

If any components are damaged, the correct function of the gearbox will no longer be ensured.

Do not install any damaged gearbox components.

NOTICE

Lubricant on the machine shaft① impairs the torque transmission

Keep the bore in the tapered bushing⑨ and the machine shaft① completely grease-free.

Do not use impure solvents and soiled cleaning cloths.

NOTICE

Avoid overloading the individual bolts

Do not exceed the maximum tightening torque for the tightening bolts④ und⑩.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 499

Loading...

Loading...