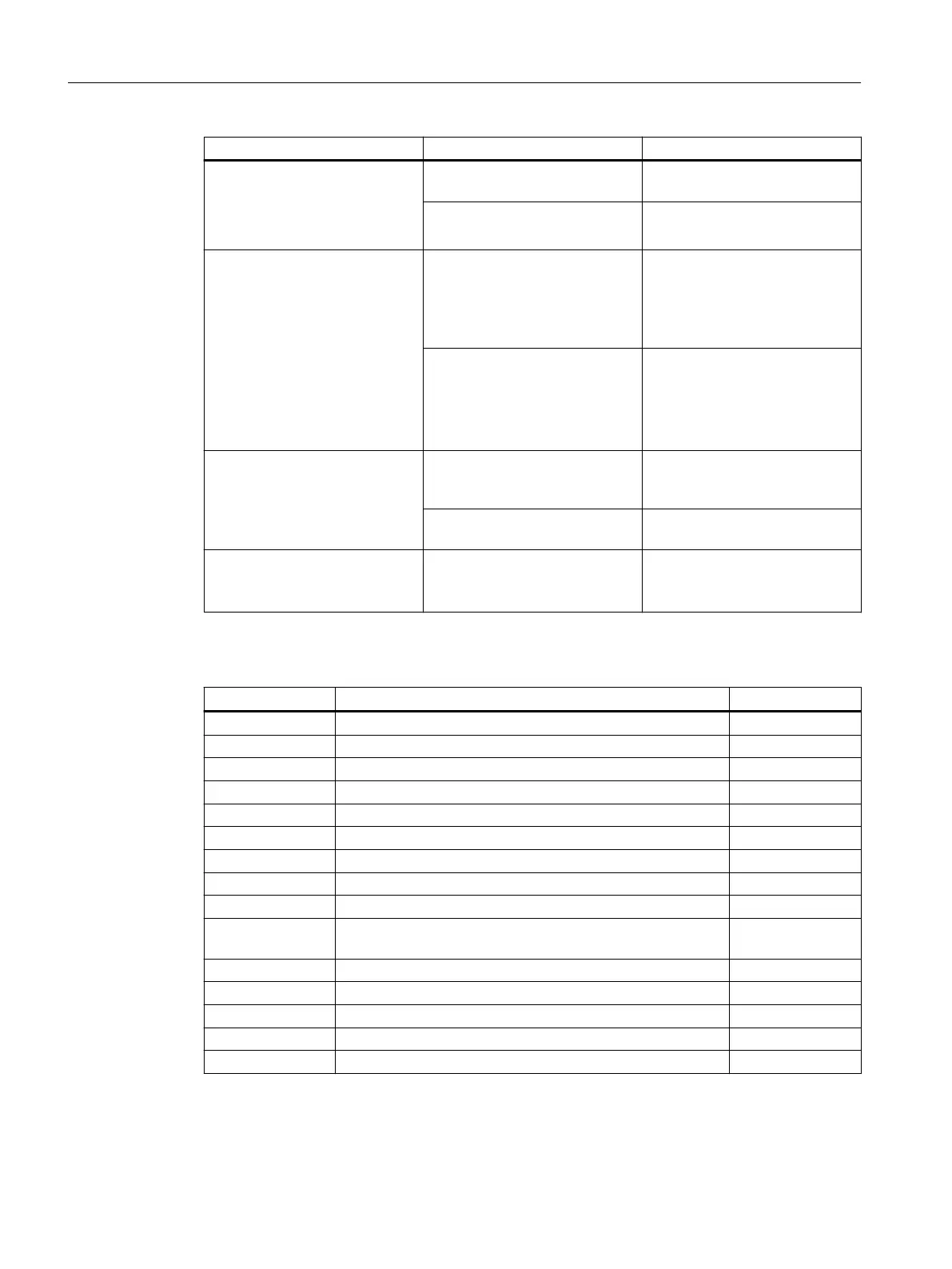

Problem Possible cause Solution

The converter signals one of the

following faults:

• F07967

• F07969

The motor has signicant pole sa‐

liency.

Change the PolID technique:

p1980 = 4 or p1980 =10.

The current is too high during

pole position identication.

Decrease the value of p329 incre‐

mentally by 10%.

The motor stalls or starts with dif‐

culty.

The converter does not generate

enough starting torque

Increase the value of p1610

or/and p1611 incrementally by

10%.

Let the motor cool down before

each start attempt.

Motor is oversaturated. Decrease p1610 and p1611 in‐

crementally by 10%.

Increase ramp-up time p1120.

Increase initial rounding time

p1130.

The motor speed tends to oscil‐

late.

The transition from open loop to

closed loop phase during acceler‐

ation is not stable.

Increase p1755 incrementally by

approx. 10% until the motor ac‐

celerates smoothly and stably.

The speed controller gain is too

high.

Optimize the speed controller.

Motor overspeed The speed overshoots after the

motor accelerates.

Increase ramp-up time p1120 or

nal rounding time p1131.

Optimize the speed controller.

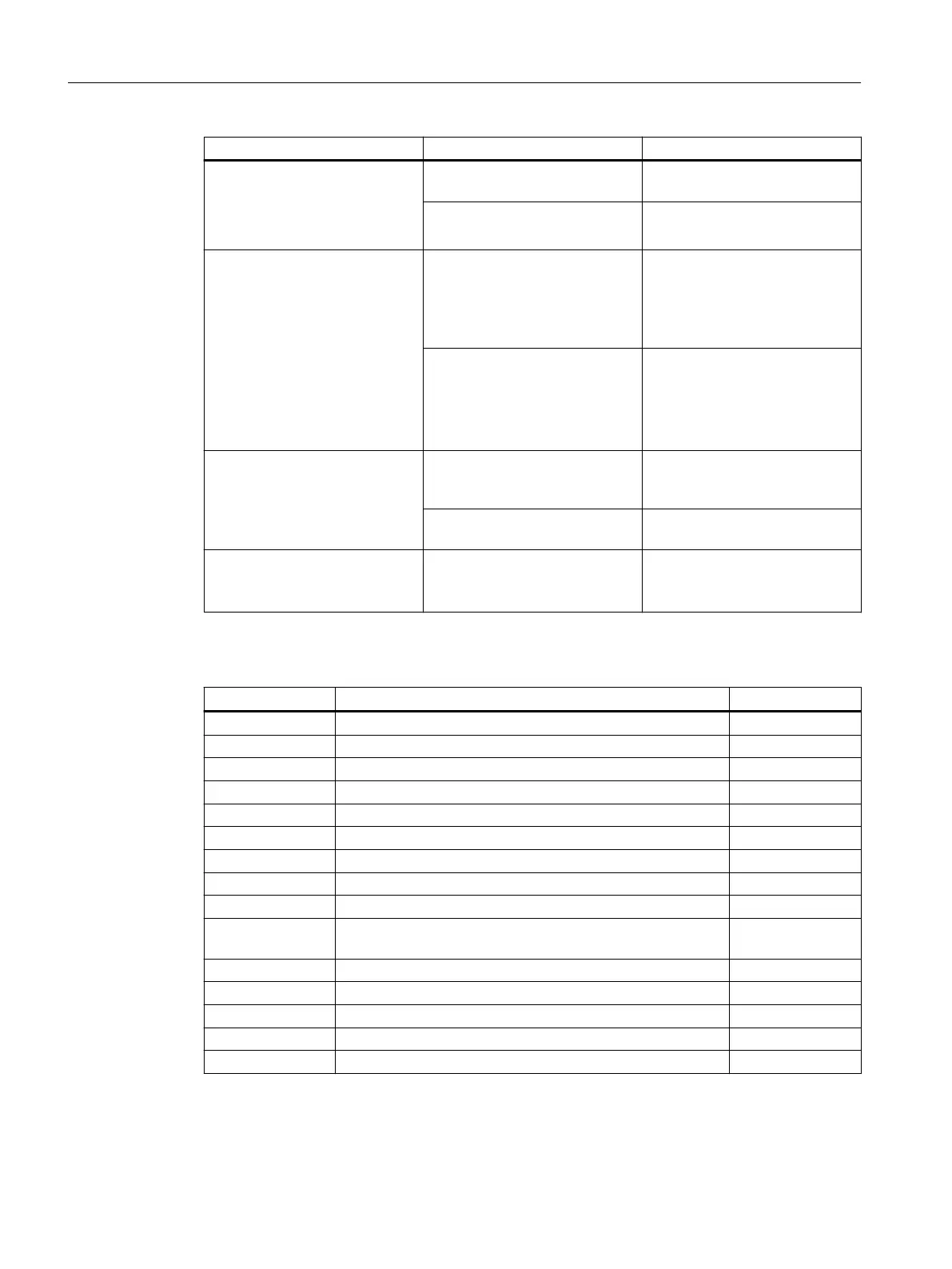

Parameters

Number Name Factory setting

p0304[M] Rated motor voltage 0 V

p0305[M] Rated motor current 0A

p0307[M] Rated motor power 0kW

p0310[M] Rated motor frequency 0Hz

p0311[M] Rated motor speed 0rpm

p0314[M] Motor pole pair number 0

p0316[M] Motor torque constant 0Nm/A

p0329[M] Motor pole position identication current 0A

p1080[D] Minimum speed 0rpm

p1120[C] Ramp-function generator ramp-up time Dependent on rat‐

ed power

p1131[C] Ramp-function generator nal rounding time 0s

p1610[D] Torque setpoint static (sensorless) 50%

p1611[D] Additional acceleration torque (sensorless) 30%

p1755[D] Motor model changeover speed sensorless operation 210000rpm

p1980 PolID technique 4

Advanced commissioning

7.20Motor control

SINAMICS G115D Wall Mounted distributed drive

296 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...