Procedure

1. Attach the torque arm⑦ to the gearbox, as shown in Torque arms with slip-on gearboxes

(Page505).

2. Remove the corrosion protection coating using white spirit or a solvent on:

– The shaft ends of the machine shaft①

– The clamping ring③

– The bronze bushing②.

3. Check the seats or edges of the hollow shaft⑥ and the machine shaft① for damage.

Contact Technical Support if you notice any damage.

4. Place the clamping ring③ on the bronze bushing②.

5. Position the bronze bushing ② with the clamping ring ③ on the machine shaft ①. Observe

the tightening torque of the tightening bolt④ and the tolerance dimensionto10.

6. Oil lightly the locating holes in the hollow shaft⑥ for the tapered bushing⑨ and bronze

bushing②. Remove any excessive oil using a clean cloth.

7. Push the gearbox with the installed torque arm⑦ on the machine shaft① against the

clamping ring③.

8. Tighten the torque arm⑦ with the bolts⑧ only gently because the gearbox must have

clearance for the subsequent mounting.

9. Ensure that the thrust collar ⑤ is placed at the correct position.

If the thrust collar ⑤ is not placed at the correct position, bring the ring ⑤ into the correct

position by tightening the tightening bolts⑩ with turned tapered bushing ⑨.

10.Place the tapered bushing⑨ on the machine shaft①.

11.Use the torque wrench to turn each of the tightening bolts⑩ equally (not crosswise),

repeating this procedure several times. Observe the tightening torque of the tightening

bolt⑩.

12.Tighten the bolts⑧ of the torque-arm fastening, as shown in Torque arms with slip-on

gearboxes (Page505).

13.Attach the rubber cover or protection cover⑪ included in the scope of delivery, as shown

in Removing and installing the protection cover (Page490).

You have installed the SIMOLOC assembly system.

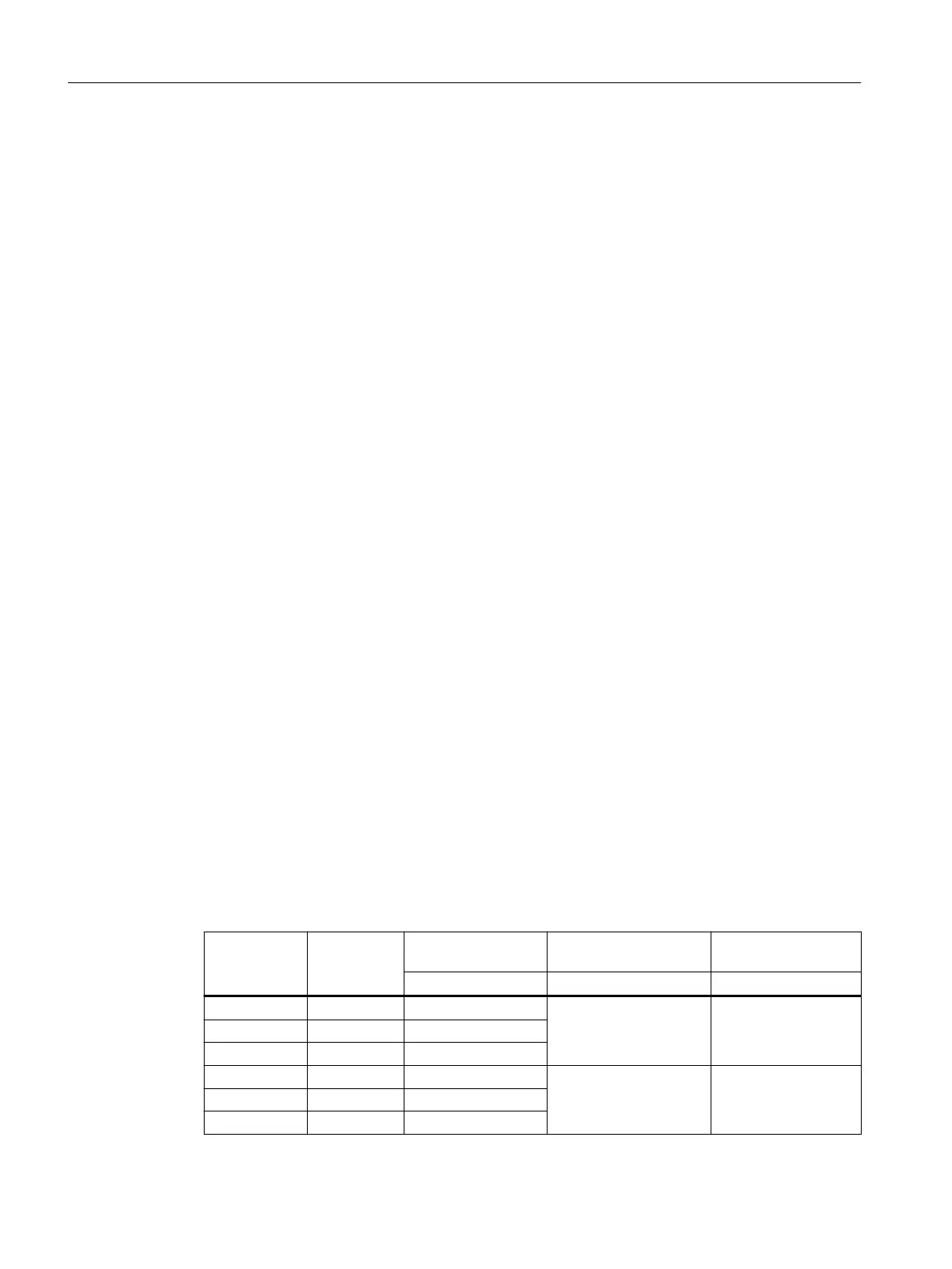

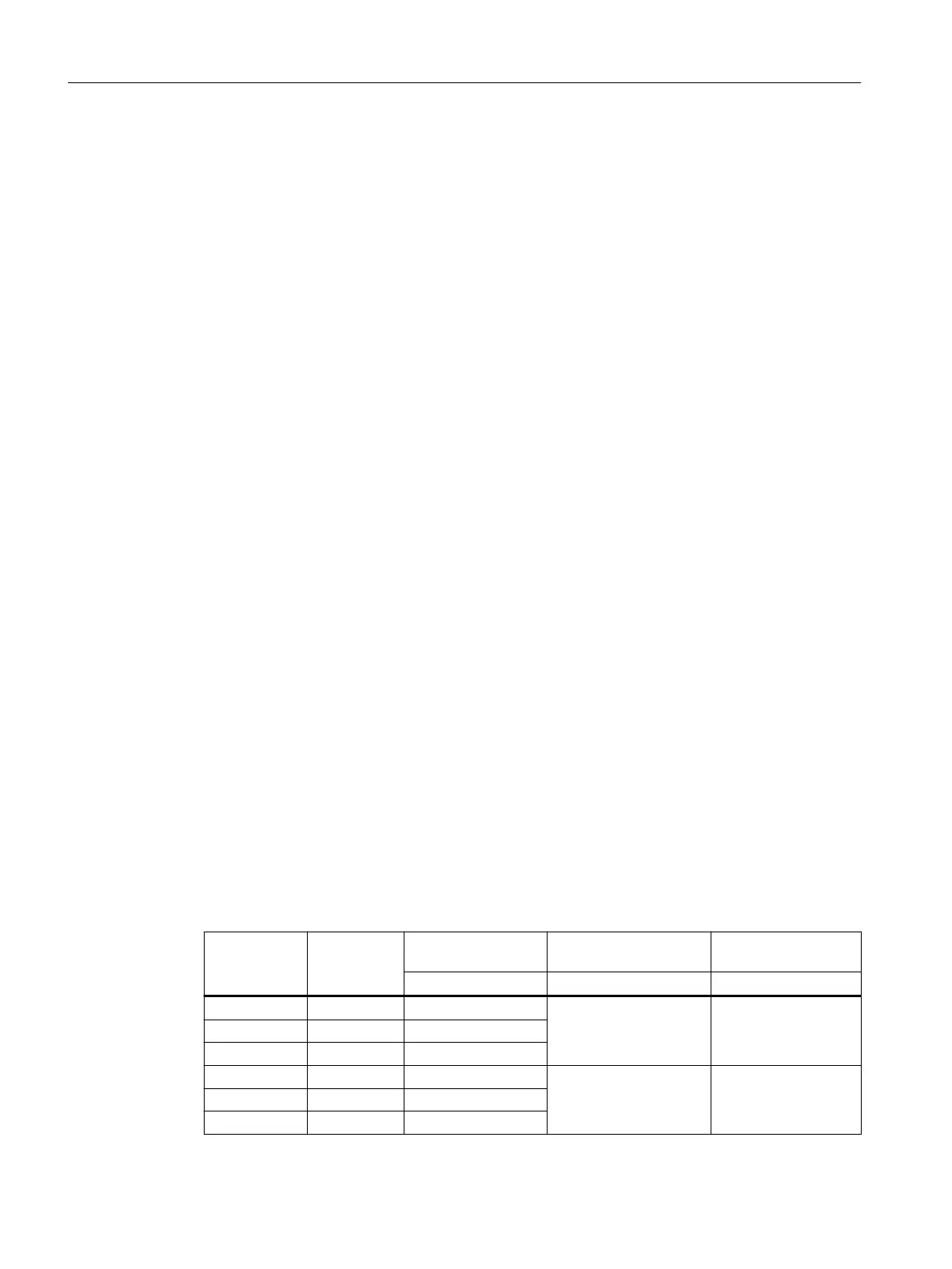

Table 12-37 Tolerance dimension, tightening bolt④ tightening torque

Gearbox type Size Tolerance dimen‐

sion to10

Thread size④ Tightening torque

mm Strength class10.9 Nm

F, B, C 29 0.6...2.1 M6 15

F, B, K, C 39 0.7...2.2

F, B, K, C 49 0.8...2.6

F, K, C 69 0.7...2.5 M8 35

F, K 79 1.4...3.2

F, K, C 89 1.5...3.4

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

502 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...