Chapter 8 Motion Control Function

(2) Conveyor belt synchronized setting disable(PCS setting)

MC_SetCartesianTransform

DoneExecute

AxesGroup AxesGroup

BOOL

BOOL

UINT UINT

LREAL TransX

LREAL TransY

Busy BOOL

CommandAborted BOOL

Error BOOL

ErrorID WORD

Active BOOL

LREAL TransZ

LREAL RotAngleA

LREAL RotAngleB

LREAL RotAngleC

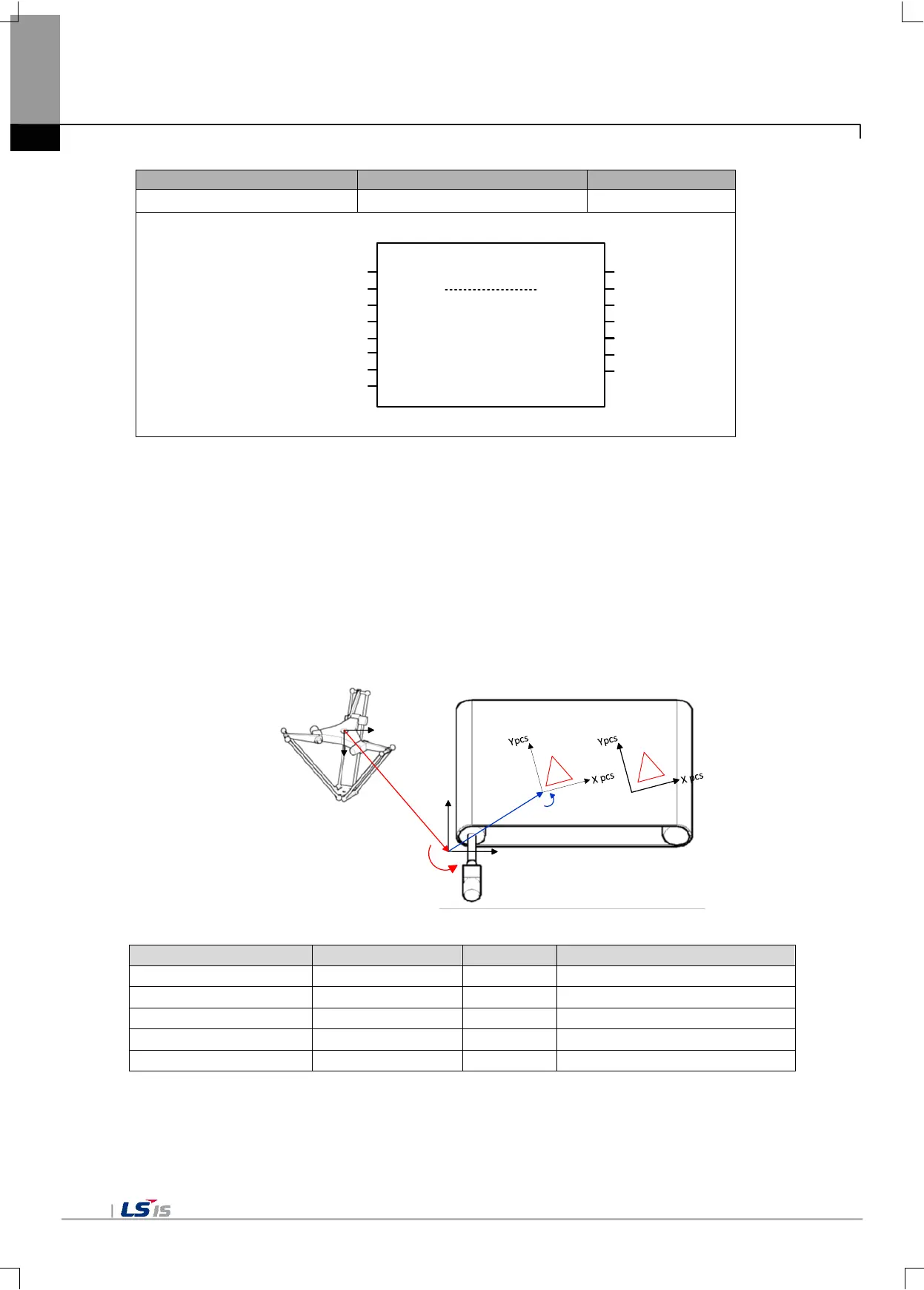

(3) Conveyor belt synchronized function operation example

The conveyor belt synchronization function begins with setting conveyor synchronization using MC_TrackConveyorBelt

function block. For MC_TrackConveyorBelt function block, enter conveyor axis value at the ConveyorAxis input, enter

the conveyor belt position from the robot's origin point at the ConveyorAxis input, and enter the position of the product

origin point from the conveyor origin point at the ConveyorOrigin input. Once MC_TrackConveyorBelt function block

setting is complete, LS_MoveLinearTimeAbsolute function block where the subsequently applied CoordSystem input is

set to PCS is operated in sync with the conveyor. Synchronized conveyor operation performs an operation of drawing a

triangle on a product. After synchronized conveyor belt operation is completed, execute LS_MoveLinearTimeAbsolute

function block where the CoordSystem is set to MCS to return to the previous status where the conveyor work is not yet

performed.

ConveyorAxis

Xconveyor

Yconveyor

Trans[conveyororigin]

Trans[objectposition]

Y mcs

X mcs

Rot[ConveyorOrgin]

Rot[objectposition]

InitTCP(-240,0,-380)

Move the robot to its initial position

Loading...

Loading...