Standards Compliance

5

5.3 UL Standards

SIEPCYEUOQ2V01A Q2V Technical Manual 177

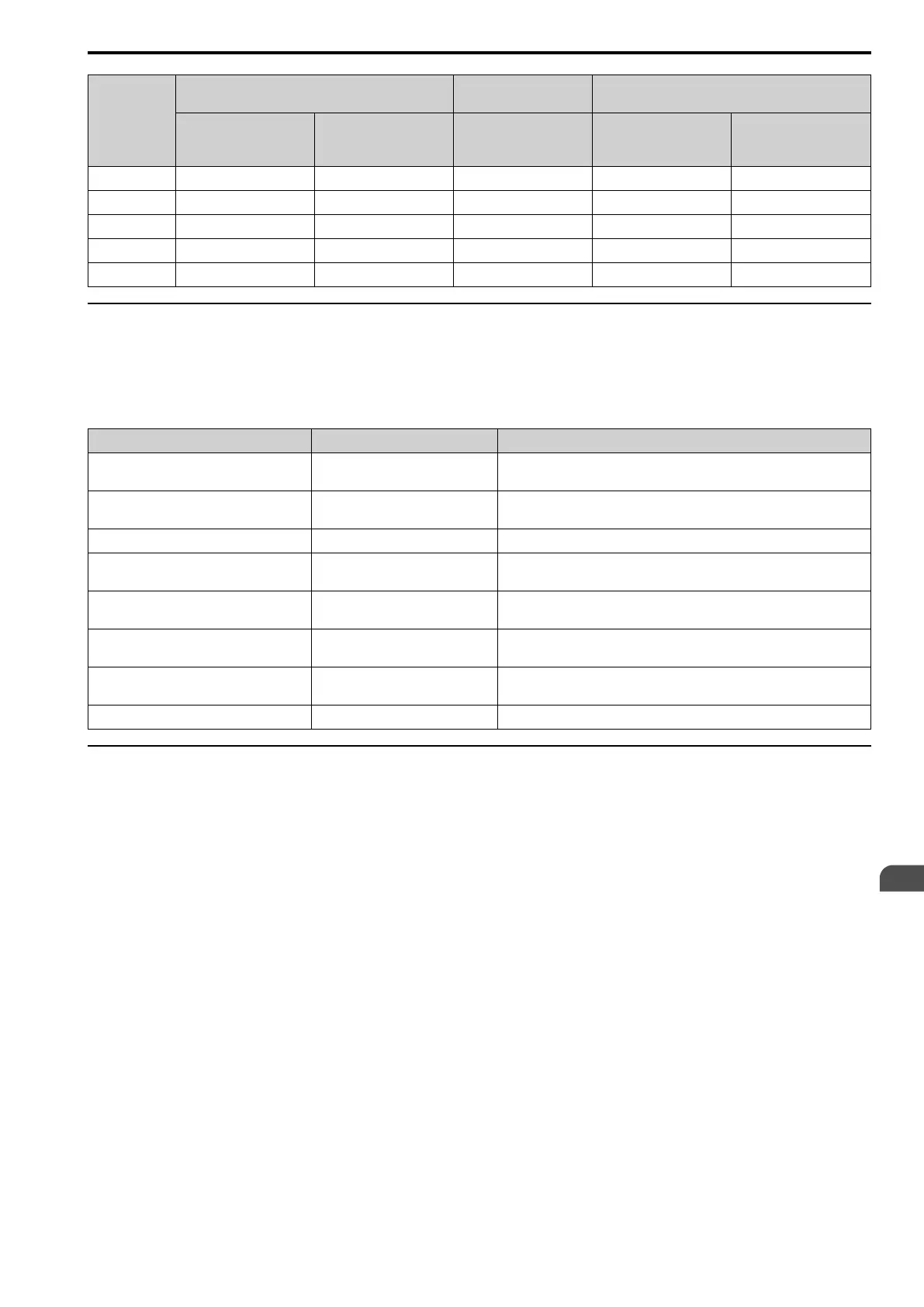

Drive Model

Maximum Applicable Motor Output

kW (HP)

Time Delay Fuse

Semiconductor Protection Fuse Rated Current

Manufacturer: EATON/Bussmann

ND HD

Class J, CC, and T Fuse

Rated Current

A

Model

Input Rated Current

A

4023 11.0 (15) 7.5 (10) - FWH-100B 100

4031 15.0 (20) 11.0 (15) - FWH-125B 125

4038 18.5 (25) 15.0 (20) - FWH-175B 175

4044 22.0 (30) 18.5 (25) - FWH-200B 200

4060 30.0 (40) 22.0 (30) - FWH-200B 200

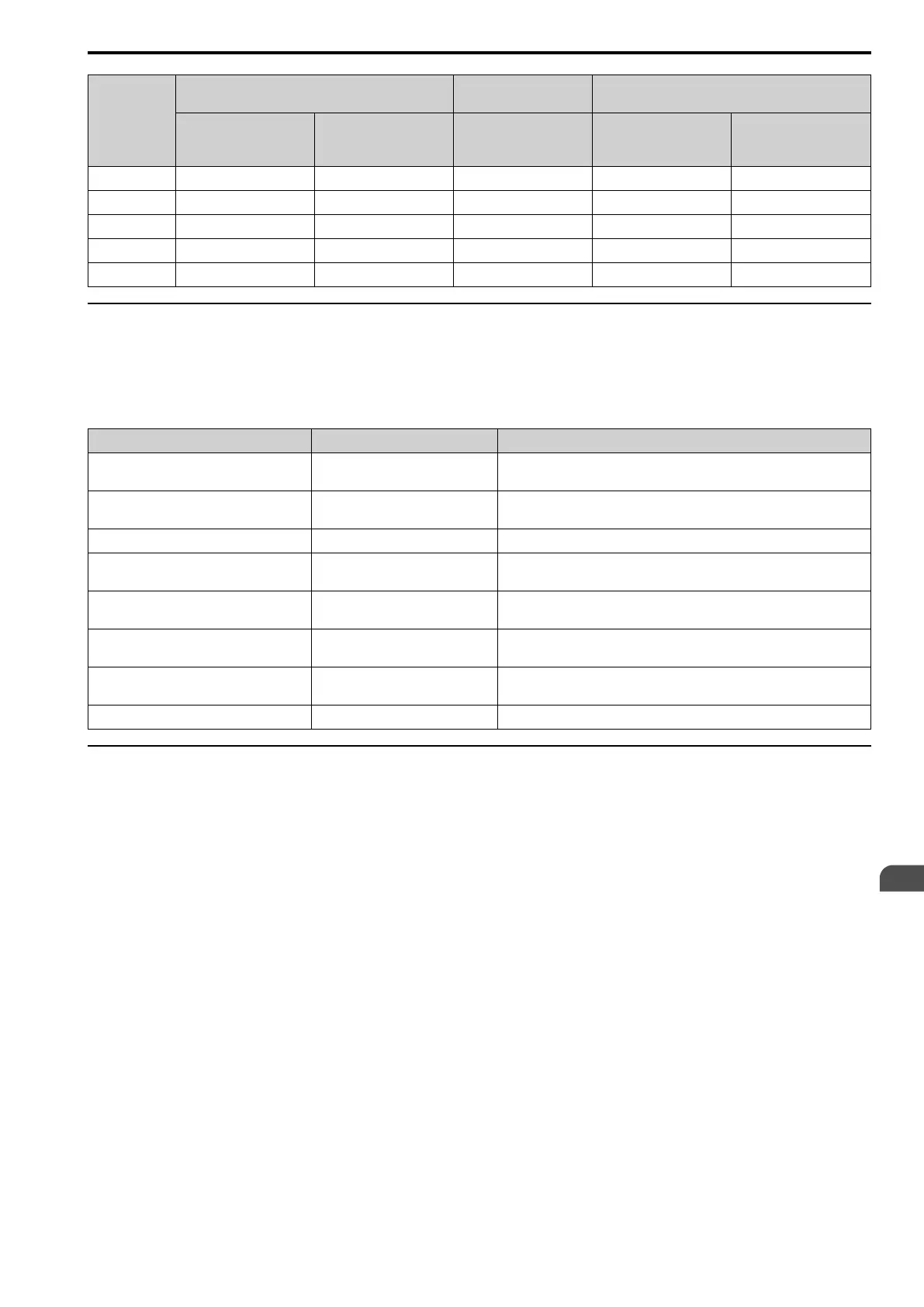

◆ Low Voltage Wiring for Control Circuit Terminals

You must provide low voltage wiring as specified by the National Electric Code (NEC), the Canadian Electric

Code, Part I (CEC), and local codes. The manufacturer recommends the NEC class 1 circuit conductor. Use the

UL approved class 2 power supply for external power supply.

Table 5.18 Control Circuit Terminal Power Supplies

Input/Output Terminals Power Supply Specifications

Digital input DI1 to DI7, D0V, DIC, D24V

Uses the LVLC power supply in the drive.

Use the UL Listed class 2 power supply for external power supply.

Analog input AI1, AI2, A0V ,+10V

Uses the LVLC power supply in the drive.

Use the UL Listed class 2 power supply for external power supply.

Analog output AO, A0V Uses the LVLC power supply in the drive.

Pulse train output PO, A0V

Uses the LVLC power supply in the drive.

Use the UL Listed class 2 power supply for external power supply.

Pulse Train Input PI, A0V

Uses the LVLC power supply in the drive.

Use the UL Listed class 2 power supply for external power supply.

Safe disable input H1, H2, HC

Uses the LVLC power supply in the drive.

Use the UL Listed class 2 power supply for external power supply.

Serial communication input/output RS485+, RS485-, A0V

Uses the LVLC power supply in the drive.

Use the UL Listed class 2 power supply for external power supply.

24 V external power supply D24V, A0V Use the UL Listed class 2 power supply.

◆ Drive Motor Overload and Overheat Protection

The drive motor overload and overheat protection function complies with the National Electric Code (NEC) and

the Canadian Electric Code, Part I (CEC).

Set the Motor Rated Current and L1-01 through L1-04 [Motor Overload Protection Select] correctly to enable

motor overload and overheat protection.

Refer to the control method and set the motor rated current with E2-01 [Mot Rated Current (FLA)], E5-03 [PM

Mot Rated Current (FLA)], or E9-06 [Motor Rated Current].

Loading...

Loading...