3.4 Main Circuit Terminal Block Wiring Procedure

72 SIEPCYEUOQ2V01A Q2V Technical Manual

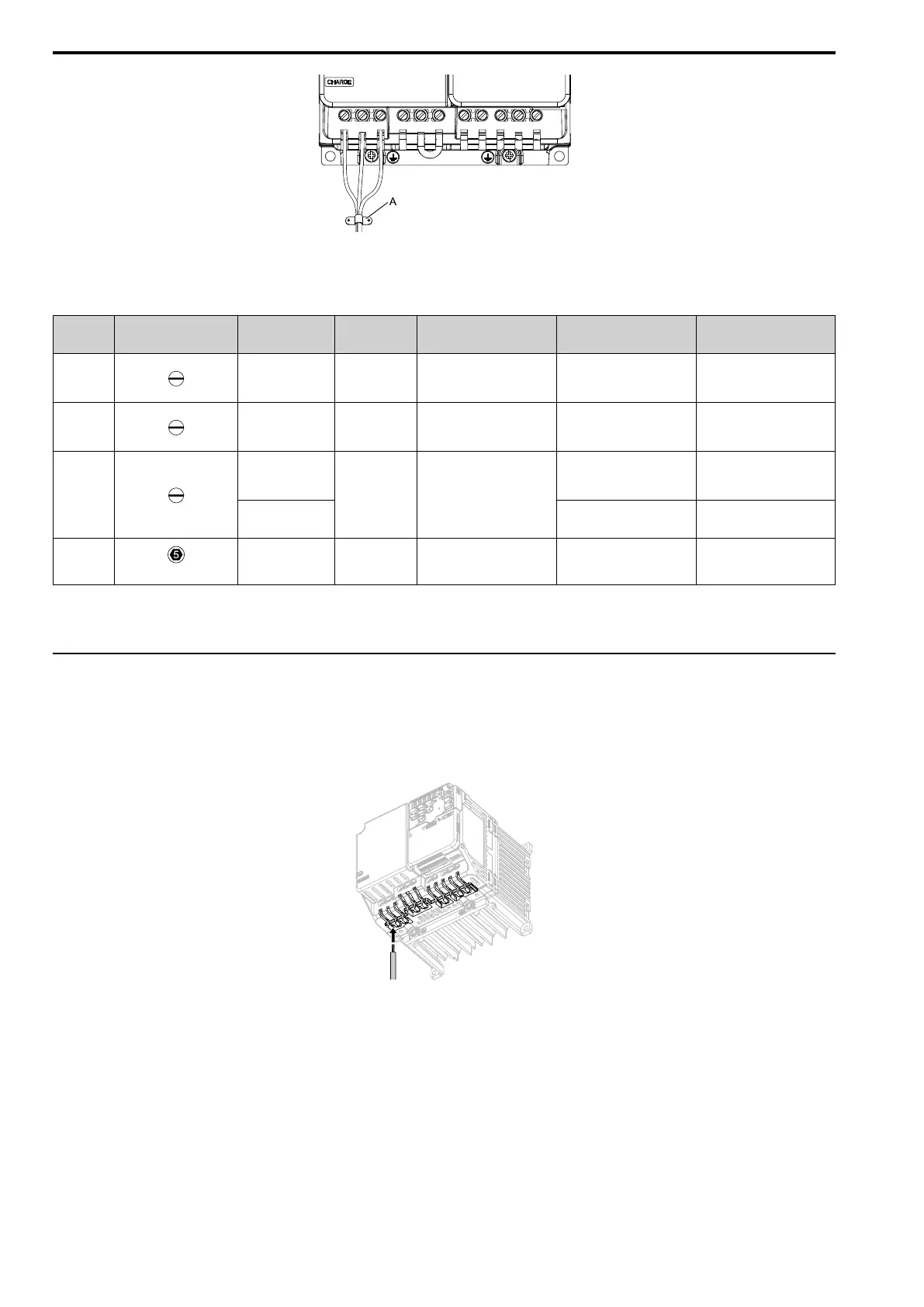

A - Cable clamp

Figure 3.17 Strain Relief Example

Table 3.4 Recommended Wiring Tools

Screw

Size

Screw Shape Wire Gauge Adapter

Bit Model

(Manufacturer)

Torque Driver Model

(Tightening Torque)

Torque Wrench

(Tightening Torque)

M3 - Bit

SF-BIT-SL 0,5X3,0-70

(PHOENIX CONTACT)

TSD-M 1,2NM

(0.3 - 1.2 N∙m

(2.7 - 10.6 in∙lb))

-

M4 - Bit

SF-BIT-SL 1,0X4,0-70

(PHOENIX CONTACT)

TSD-M 3NM

(1.2 - 3.0 N∙m

(10.6 - 26.6 in∙lb))

-

M5

*1

≤ 25 mm

2

(AWG 10)

Bit

SF-BIT-SL 1,2X6,5-70

(PHOENIX CONTACT)

TSD-M 3NM

(1.2 - 3.0 N∙m

(10.6 - 26.6 in∙lb))

-

≥ 30 mm

2

(AWG 8)

-

4.1 - 4.5 N∙m

(36.3 - 39.8 in∙lb)

*2 *3

M6

(WAF: 5 mm)

- Bit

SF-BIT-HEX 5-50

(PHOENIX CONTACT)

-

5 - 9 N∙m

(44.3 - 79.7 in∙lb)

*2 *3

*1 When you wire drive models 2042, 2056, 4031, 4038, 4044, and 4060, select the correct tools for the wire gauge.

*2 Use 6.35 mm (0.25 in) bit socket holder.

*3 Use a torque wrench that can apply this torque measurement range.

◆ Main Circuit Terminal Block Wiring Procedure

When terminals R/L1, S/L2, T/L3, -, +1, and +2 have IP20 protection covers, remove them.

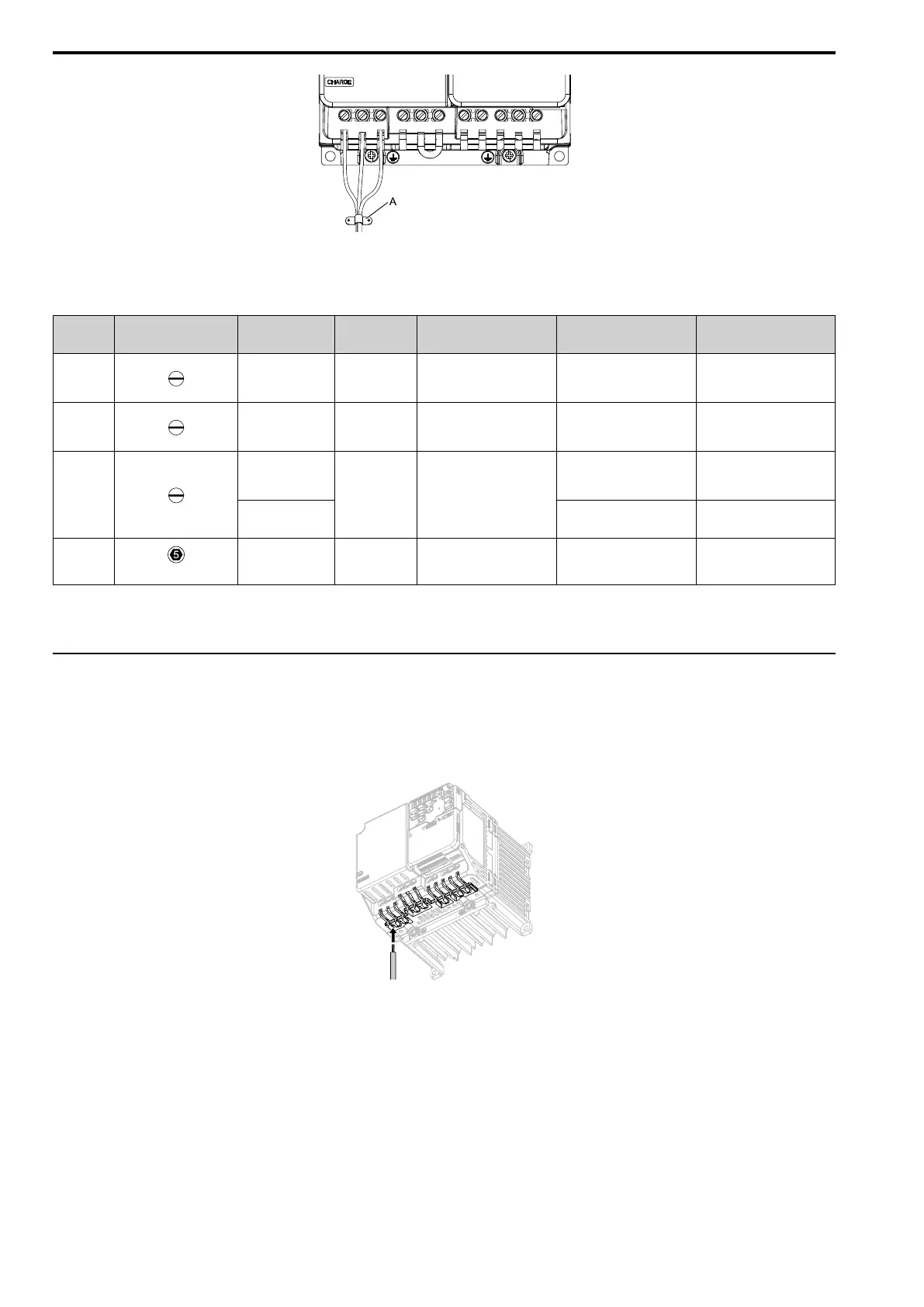

1. Put a wire with prepared ends into the main circuit terminal block.

Look through the opening in the drive case to make sure that you correctly installed the wires into the

terminal block.

Figure 3.18 Install the Electrical Wire

Note:

There is a jumper between terminals +1 and +2. Remove the jumper, then wire to terminals +1 and +2.

Loading...

Loading...