Troubleshooting

7

7.7 Auto-Tuning Errors

SIEPCYEUOQ2V01A Q2V Technical Manual 251

7.7 Auto-Tuning Errors

If the drive detects an Auto-Tuning error, the keypad will show the error and the motor will coast to stop.

The drive will not send notification signals for faults and alarms when Auto-Tuning errors occur.

Two types of Auto-Tuning errors are: Endx and Erx:

• Endx identifies that Auto-Tuning has successfully completed with calculation errors. Find and repair the cause

of the error and do Auto-Tuning again, or set the motor parameters manually. You can use the drive in the

application if you cannot find the cause of the Endx error.

• Erx identifies that Auto-Tuning was not successful. Find and repair the cause of the error and do Auto-Tuning

again.

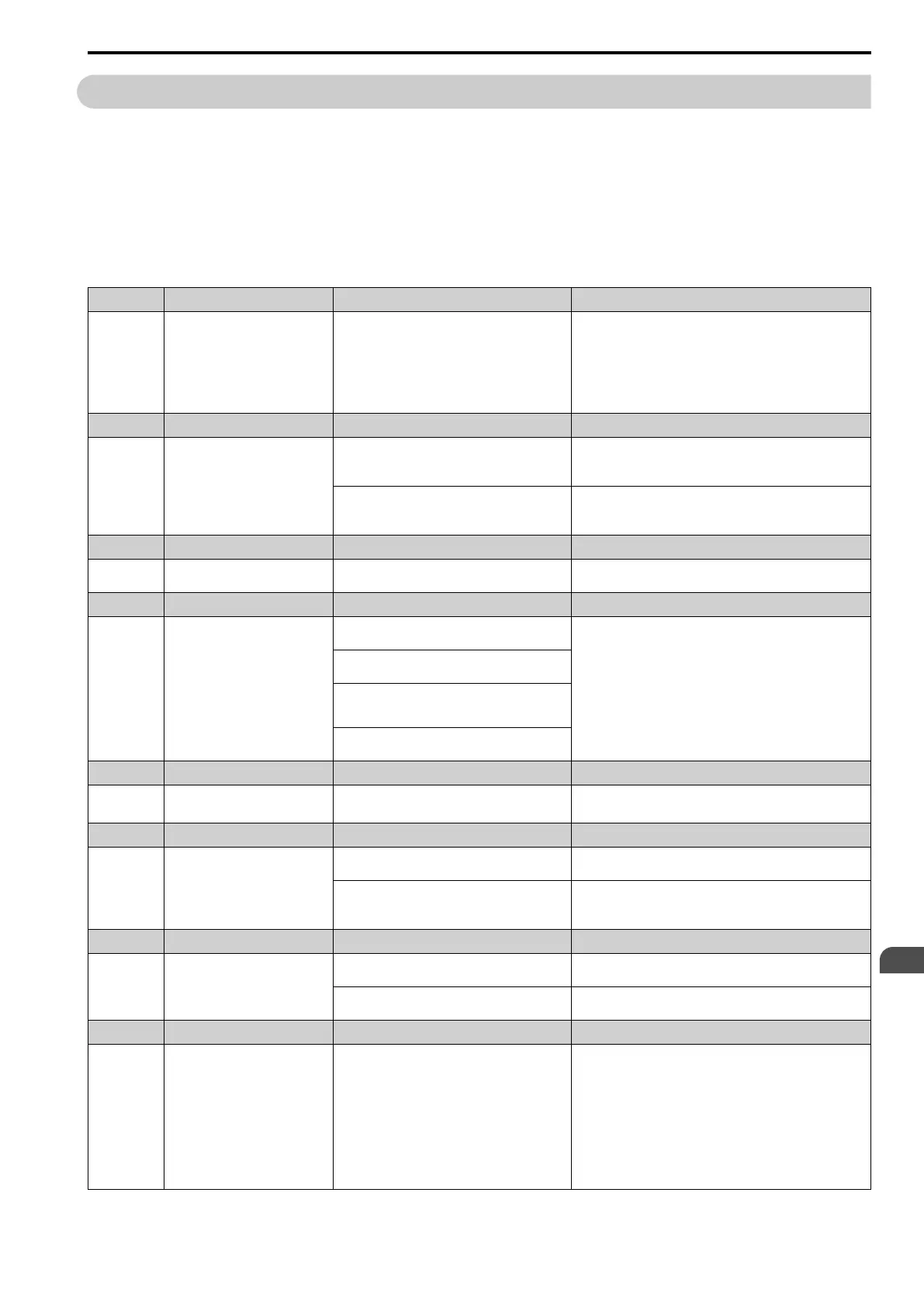

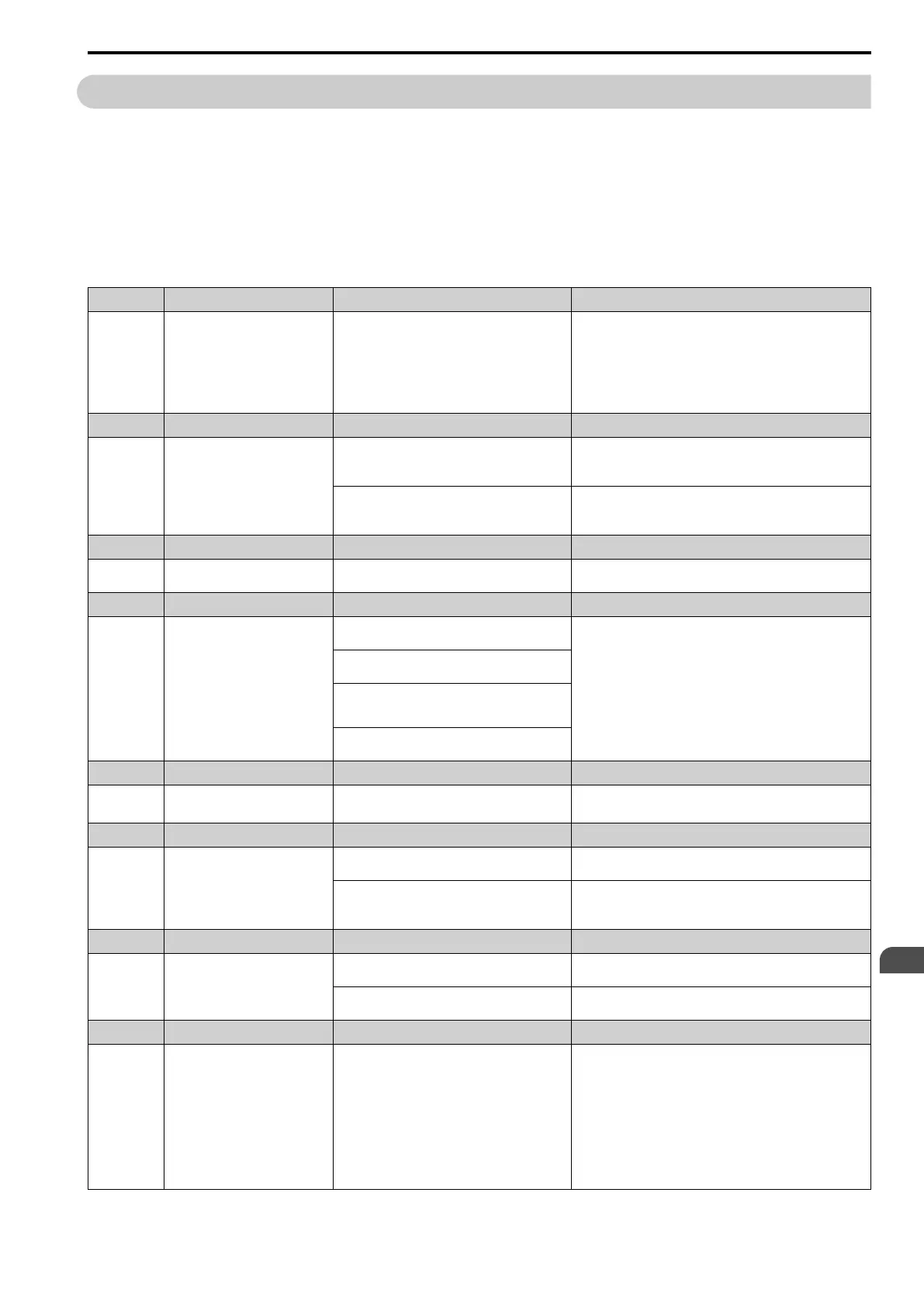

Code Name Causes Possible Solutions

End1 Excessive Rated Voltage Setting

The torque reference was more than 20% during

Auto-Tuning or the no-load current that was

measured after Auto-Tuning is more than 80%.

• Make sure that the input motor nameplate data is correct.

• Do Auto-Tuning again and correctly set the motor nameplate

data.

• If you can uncouple the motor and load, remove the motor

from the machine and do Rotational Auto-Tuning again.

• If you cannot uncouple the motor and load, use the results

from Auto-Tuning.

Code Name Causes Possible Solutions

End2 Iron Core Saturation Coefficient

The motor nameplate data entered during Auto-

Tuning is incorrect.

• Make sure that the input motor nameplate data is correct.

• Do Auto-Tuning again and correctly set the motor nameplate

data.

Auto-Tuning results were not in the applicable

parameter setting range, and E2-07 or E2-08 [Mbus

Reg1 Bit Select] have temporary values.

• Examine and repair damaged motor wiring.

• If you can uncouple the motor and load, remove the motor

from the machine and do Rotational Auto-Tuning again.

Code Name Causes Possible Solutions

End3 Rated Current Setting Alarm

The rated current value is incorrect. Do Auto-Tuning again and set the correct rated current shown on

the motor nameplate.

Code Name Causes Possible Solutions

End4 Adjusted Slip Calculation Error

The Auto-Tuning results were not in the applicable

parameter setting range.

The motor rated slip that was measured after

Stationary Auto-Tuning was 0.2 Hz or lower.

The motor rated slip that was measured after

compensation with E2-08 [Mbus Reg1 Bit Select] is

not in the applicable range.

The secondary resistor measurement results were

not in the applicable range.

• Make sure the input motor nameplate data is correct.

• Do Rotational Auto-Tuning again and correctly set the motor

nameplate data.

• If you cannot uncouple the motor and load, do Stationary

Auto-Tuning 2.

Code Name Causes Possible Solutions

End5 Resistance Tuning Error

The Auto-Tuning results of the Line-to-Line

Resistance were not in the applicable range.

• Make sure that the input motor nameplate data is correct.

• Examine and repair damaged motor wiring.

Code Name Causes Possible Solutions

End6 Leakage Inductance Alarm

The Auto-Tuning results were not in the applicable

parameter setting range.

Make sure that the input motor nameplate data is correct, and do

Auto-Tuning again.

A1-02 [Control Method] setting is not applicable. • Examine the value set in A1-02.

• Make sure that the input motor nameplate data is correct, and

do Auto-Tuning again.

Code Name Causes Possible Solutions

End7 No-Load Current Alarm

The Auto-Tuning results of the motor no-load

current value were not in the applicable range.

Examine and repair damaged motor wiring.

Auto-Tuning results were less than 5% of the motor

rated current.

Make sure that the input motor nameplate data is correct, and do

Auto-Tuning again.

Code Name Causes Possible Solutions

End8 HFI Alarm

• Inductance saliency ratio (E5-07/E5-06) is too

small.

• The drive cannot find the n8-36 [HFI Signal

Frequency] value.

• Set the correct value on the motor nameplate to [E5: PM

MOTOR SETTINGS] or do rotational/stationary Auto-Tuning.

• When it is necessary to set n8-35 = 2 [InitRotorPos Selection

= HiFreq Injection] or n8-57 = 1 [High-Freq Injection =

Enabled], make sure that there is no unusual noise in the low

speed range (10% or less) and that the motor does not rotate in

reverse at start.

Note:

If the drive detects End8, it will automatically set n8-35 =1

[Pull-In] and n8-57 = 0 [Disabled]. Do not change the

settings unless necessary.

Loading...

Loading...