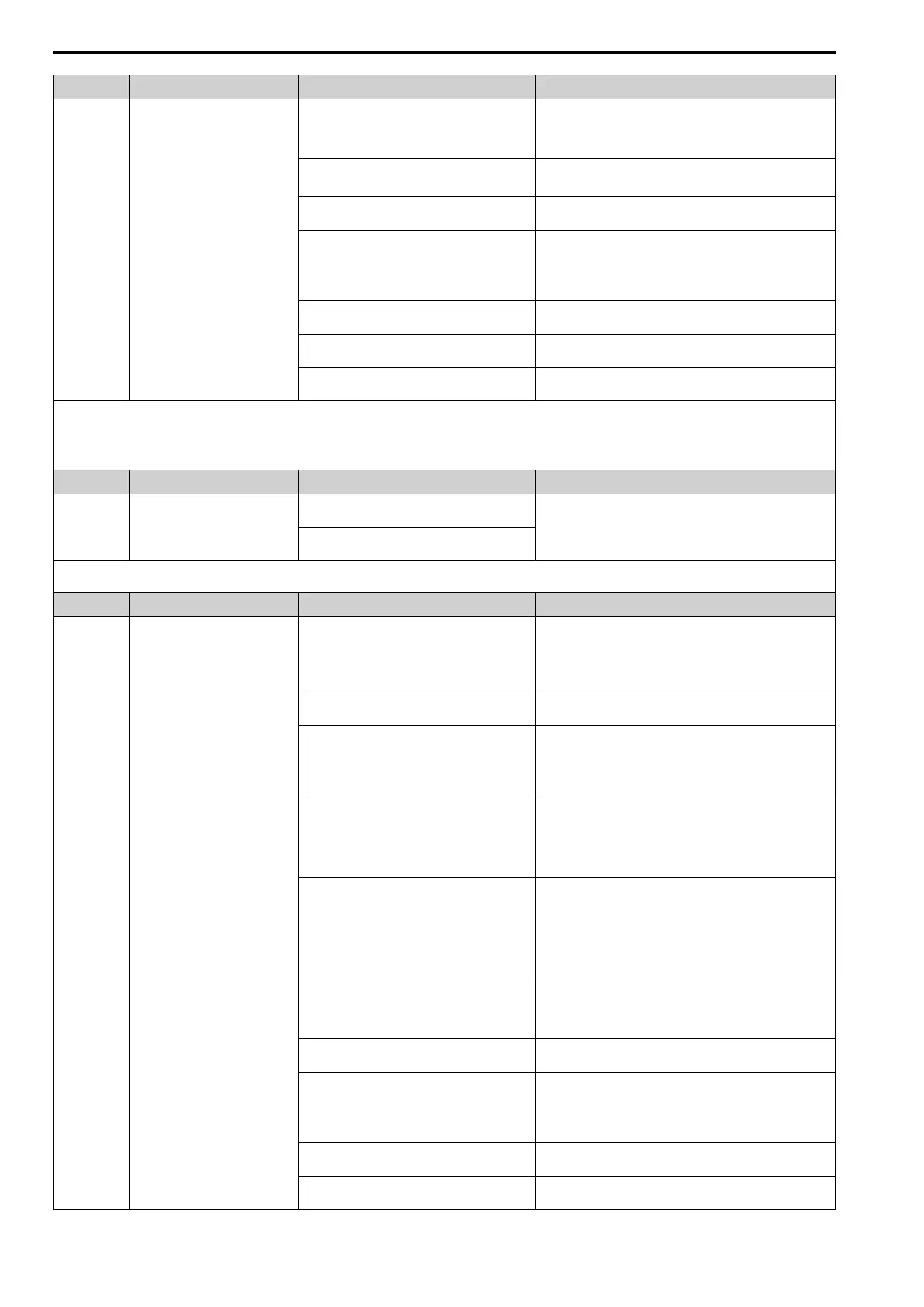

7.4 Faults

228 SIEPCYEUOQ2V01A Q2V Technical Manual

Code Name Causes Possible Solutions

LSo Low Speed Motor Step-Out

The motor code set incorrectly. • Set E5-01 [PM Mot Code Selection] correctly as specified by

the motor.

• For specialized motors, refer to the motor test report and set

E5-xx correctly.

The load is too large. • Decrease the load.

• Replace the drive and motor with larger capacity models.

An external force on the load side caused the motor

to move at start.

Find and repair problems on the load side that cause the motor to

rotate from the load side.

The drive incorrectly detected the motor magnetic

pole position.

• Set b3-01 = 1 [SpSrch@Start Selection = Enabled].

• If the value for U6-57 [PoleDis IdDifVal] is lower than 819,

increase the value set in n8-84 [Polarity Det Current]. Consult

the motor manufacturer for information about maximum

setting values.

The setting of n8-84 [Polarity Det Current] is too

low.

Increase the n8-84 setting from the default. Consult the motor

manufacturer for information about maximum setting values.

Incorrect values set in L8-93 [Lso Detect Time], L8-

94 [Lso Detect Level], and L8-95 [Lso Amount].

Increase the values set in L8-93 to L8-95.

The drive incorrectly detected the motor magnetic

pole position.

If you are using an IPM motor, do High Frequency Injection

Auto-Tuning.

Note:

• The drive detects this fault if it detects step-out while running at low speed.

• Do a Fault Reset to clear the fault.

• LSo is a protective function that stops the motor and stops the reverse run if a motor without a motor code incorrectly detects the initial polarity. To quickly detect motor

reversal, decrease the values set in L8-93 to L8-95 to a range in which the drive does not malfunction.

Code Name Causes Possible Solutions

nSE Node Setup Error

The H1-xx = 7E [Node Setup] terminal was

activated during run.

The drive received a Run command while the Node

Setup function was active.

Stop the drive when the Node Setup function is in use.

Note:

Do a Fault Reset to clear the fault.

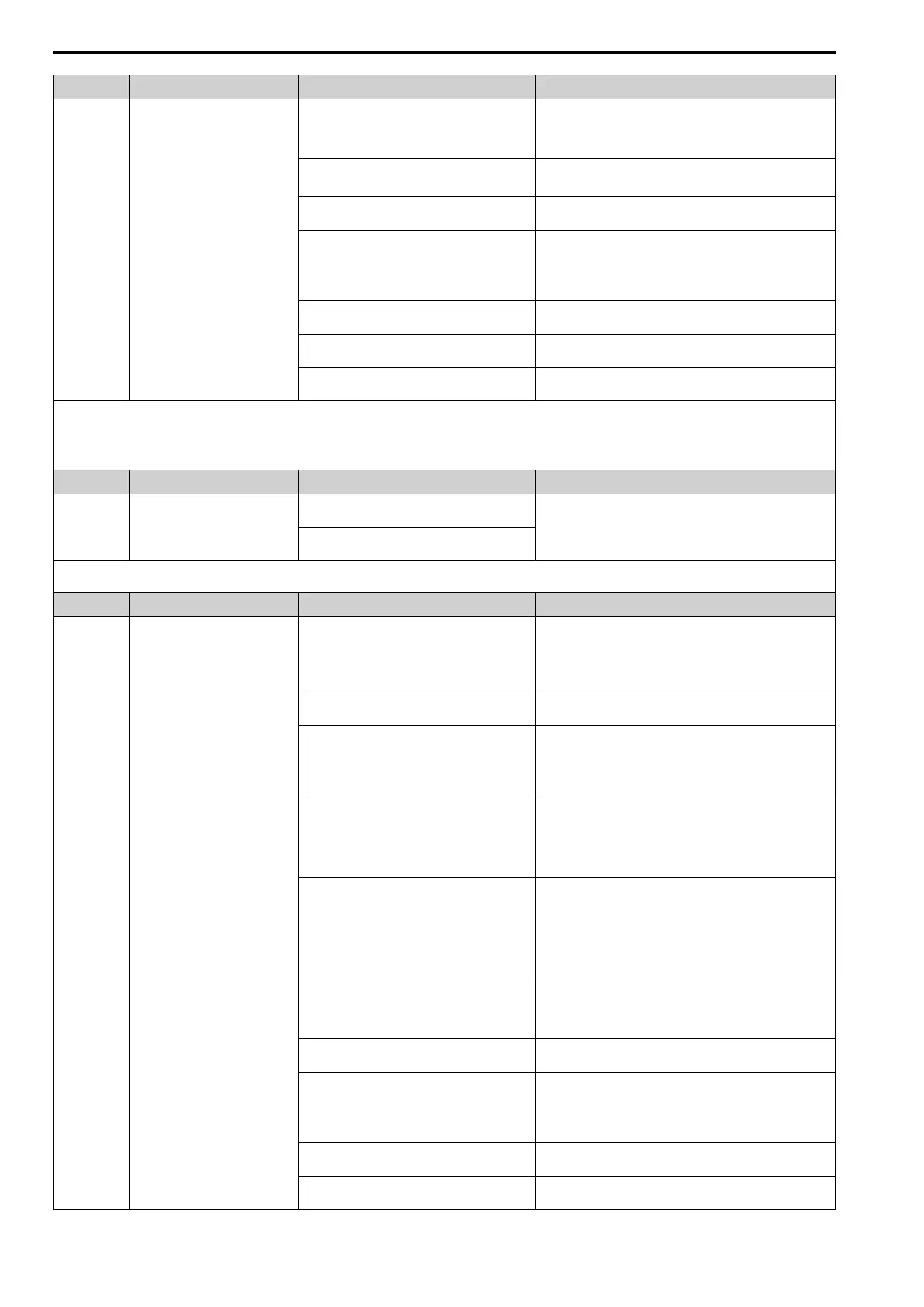

Code Name Causes Possible Solutions

oC Overcurrent

The load is too heavy. • Measure the current flowing into the motor.

• Replace the drive with a larger capacity model if the current

value is more than the drive rated current.

• Decrease the load or replace with a larger drive to prevent

sudden changes in the current level.

Overheating caused damage to the motor or the

motor insulation is not satisfactory.

Measure the motor insulation resistance, and replace the motor if

there is electrical conduction or unserviceable insulation.

The motor main circuit cable is contacting ground

to make a short circuit.

• Examine the motor main circuit cable for damage, and repair

short circuits.

• Measure the resistance between the motor main circuit cable

and the ground terminal. If there is electrical conduction,

replace the cable.

A short circuit or ground fault on the drive output

side caused damage to the output transistor of the

drive.

• Make sure that there is not a short circuit in terminal B1 and

terminals U/T1, V/T2, and W/T3. Make sure that there is not a

short circuit in terminals - and terminals U/T1, V/T2, and W/

T3.

• If there is a short circuit, contact the manufacturer or your

nearest sales representative.

The acceleration time is too short. • Calculate the torque necessary during acceleration related to

the load inertia and the specified acceleration time.

• Increase the values set in C1-01, C1-03, C1-05, or C1-07

[Acceleration Times] to get the necessary torque.

• Increase the values set in C2-01 to C2-04 [S-Curve

Characteristics] to get the necessary torque.

• Replace the drive with a larger capacity model.

The drive is trying to operate a specialized motor or

a motor that is larger than the maximum applicable

motor output of the drive.

• Examine the motor nameplate, the motor, and the drive to

make sure that the drive rated current is larger than the motor

rated current.

• Replace the drive with a larger capacity model.

A magnetic contactor was switched at the output. Set the operation sequence to not turn ON or OFF the magnetic

contactor while the drive is outputting voltage.

The V/f pattern settings are incorrect. • Examine the ratios between the V/f pattern frequency and

voltage. Decrease the voltage if it is too high compared to the

frequency.

• Adjust E1-04 to E1-10 [V/f Pattern Parameters]. For motor 2,

adjust E3-04 to E3-10.

The torque compensation gain is too large. Decrease the value set in C4-01 [Trq Comp Gain] to make sure

that the motor does not stall.

Electrical interference caused a problem. Examine the control circuit lines, main circuit lines, and ground

wiring, and decrease the effects of electrical interference.

Loading...

Loading...