7.4 Faults

232 SIEPCYEUOQ2V01A Q2V Technical Manual

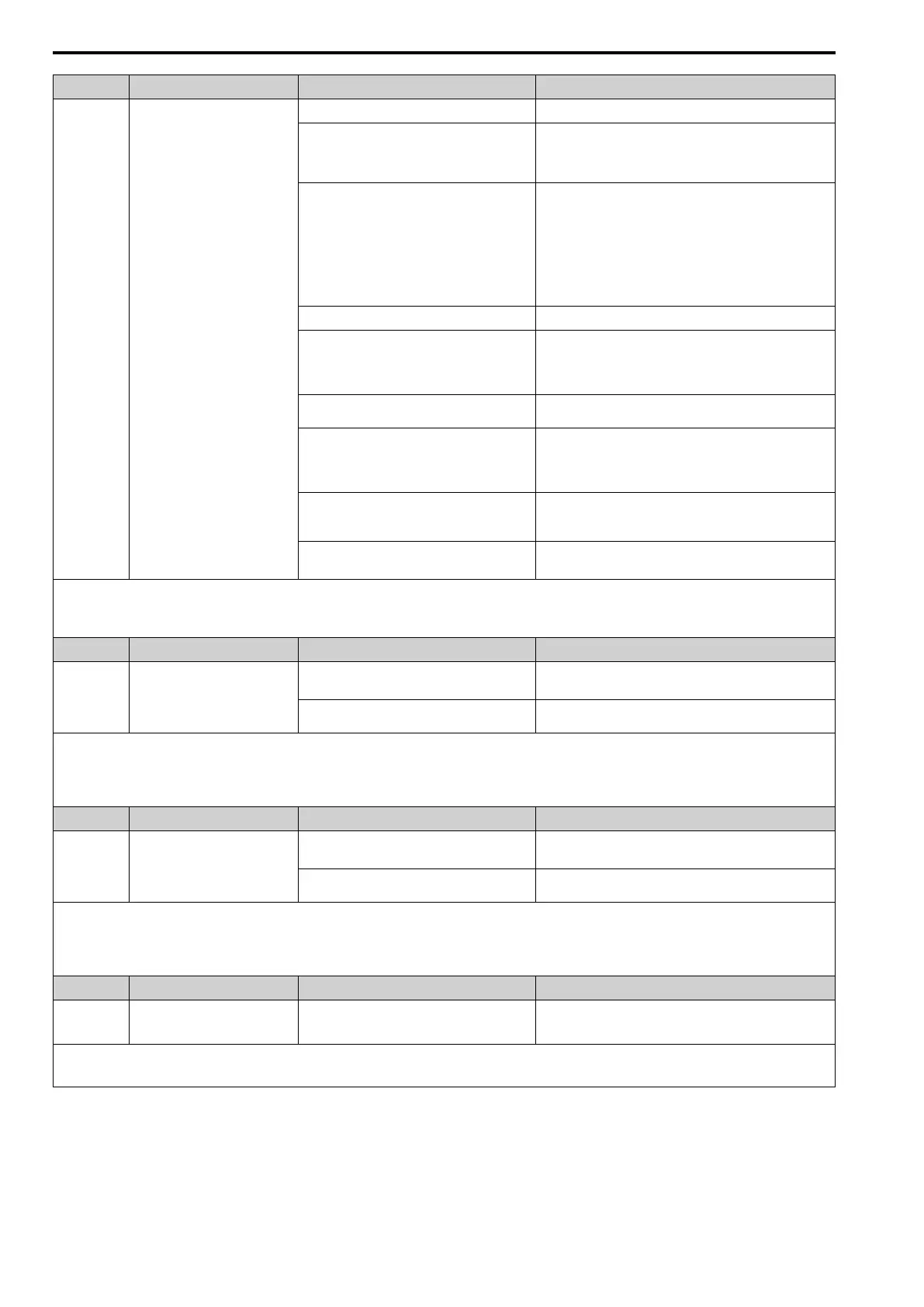

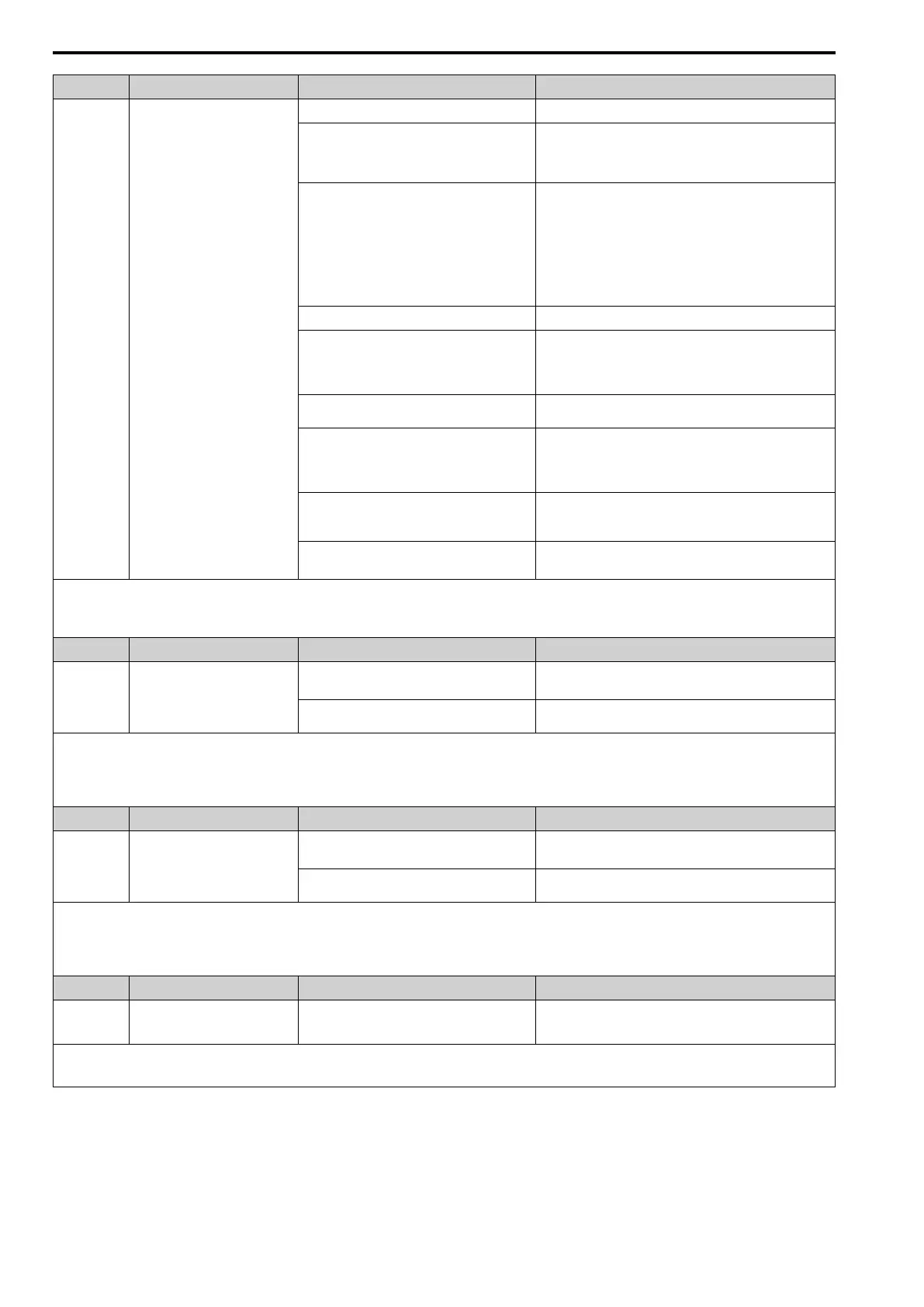

Code Name Causes Possible Solutions

oL2 Drive Overload

The load is too large. Decrease the load.

The acceleration/deceleration times or cycle times

are too short.

• Examine the acceleration/deceleration times and the motor

start/stop frequencies (cycle times).

• Increase the values set in C1-01 to C1-08 [Acceleration/

Deceleration Times].

The V/f pattern does not fit the motor qualities. • Examine the ratios between the V/f pattern frequency and

voltage. Decrease the voltage if it is too high compared to the

frequency.

• Adjust E1-04 to E1-10 [V/f Pattern Parameters]. Decrease the

values set in E1-08 [Mid A Voltage] and E1-10 [Min Output

Voltage]. For motor 2, adjust E3-04 to E3-10.

Note:

If the values set in E1-08 and E1-10 are too low, the overload

tolerance will decrease at low speeds.

The drive capacity is too small. Replace the drive with a larger capacity model.

Overload occurred while running at low speed. • Decrease the load when running at low speed.

• Replace the drive with a larger capacity model.

• Decrease the value set in C6-02 [Carrier Frequency

Selection].

The torque compensation gain is too large. Decrease the value set in C4-01 [Trq Comp Gain] to make sure

that the motor does not stall.

The speed search-related parameters are set

incorrectly.

• Examine the settings for all speed search-related parameters.

• Adjust b3-03 [SpSrch Deceleration Time].

• Set b3-24 = 1 [SpSrch Method Selection = Speed Estimation]

after Auto-Tuning.

Phase loss in the input power supply is causing the

output current to change.

• Correct errors with the wiring for main circuit drive input

power.

• Make sure that there is no phase loss, and repair problems.

Overload occurred during overexcitation

deceleration.

• Decrease the value set in n3-13 [OverExcBr Gain].

• Decrease the value set in n3-21 [OverExcBr Current Level].

Note:

• The drive detects this fault if the electronic thermal protector of the drive started the drive overload protection.

• Do a Fault Reset to clear the fault.

• L5-07 [OL1-4 Auto-Reset Select] disables the Auto Restart function.

Code Name Causes Possible Solutions

oL3 Overtorque Detection 1

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the fault.

The parameters are incorrect for the load. Adjust L6-02 [Trq Det1 Level] and L6-03 [Trq Det1 Time]

settings.

Note:

• The drive detects this fault if the drive output current is more than the level set in L6-02 for longer than L6-03.

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the Stopping Method set in L6-01 [Trq Det1 Select].

• L5-07 [OL1-4 Auto-Reset Select] disables the Auto Restart function.

Code Name Causes Possible Solutions

oL4 Overtorque Detection 2

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the fault.

The parameters are incorrect for the load. Adjust L6-05 [Trq Det2 Level] and L6-06 [Trq Det2 Time]

settings.

Note:

• The drive detects this fault if the drive output current is more than the level set in L6-05 for longer than L6-06.

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the Stopping Method set in L6-04 [Trq Det2 Select].

• L5-07 [OL1-4 Auto-Reset Select] disables the Auto Restart function.

Code Name Causes Possible Solutions

oL5 Mechanical Weakening Detection 1

The drive detected overtorque as specified by the

conditions for mechanical weakening detection set

in L6-08 [MechF Enable].

Do a deterioration diagnostic test on the machine side.

Note:

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the Stopping Method set in L6-08.

Loading...

Loading...