12 - 7

12 Troubleshooting

High-function General-purpose Inverter RX2 Series User’s Manual

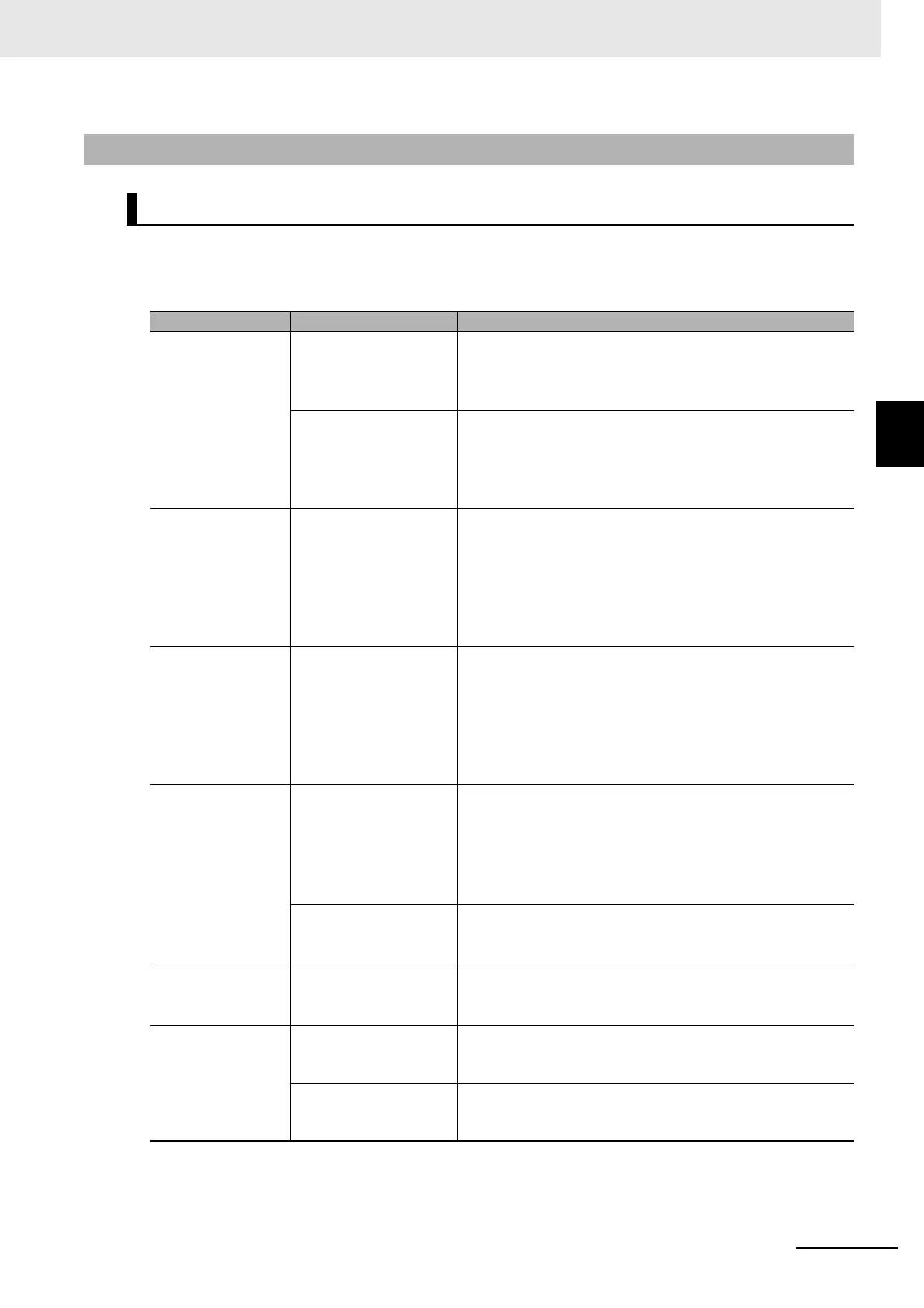

12-2 Error No. and Its Measure

12

12-2-2 Details about Errors

A large current flowing in the inverter results in a failure. To prevent this, the inverter turns OFF its out-

put. By setting the parameter, you can perform retries for a fixed number of times without generating an

error. Overcurrent level can be set in the [bb160].

12-2-2 Details about Errors

E001 Overcurrent Error

Occurrence Estimated cause(s) Exemplar measures to be taken

Error occurred

abruptly during oper-

ation.

A steep load change

occurred.

• Overcurrent suppression function and Overload limit func-

tion are effective to suppress overcurrent.

• When the vector control is used, the situation may be

improved by adjusting the response to control in [HA115].

Hunting of motor

• The situation may be improved by setting the IM motor

capacity in [Hb102], the number of IM poles in [Hb103], or

the auto-tuning selection in [HA-01].

• The situation may be improved by adjusting stabilization

control gain in [HA110].

Error occurred

during acceleration.

• Insufficient accelera-

tion time

• Insufficient accelera-

tion torque

• Load inertia is large.

• Friction torque is large.

• Setting longer acceleration time in [FA-10] can ease the

insufficient acceleration torque.

• When acceleration torque is required, the situation may be

improved by adjusting the manual torque boost function, or

by operating the inverter and making adjustments with con-

trol method in [AA121].

• Re-examination of load condition may improve the situation.

Error occurred

during deceleration.

• Insufficient decelera-

tion time

• Insufficient regenera-

tive torque

• Load inertia is large.

• Setting longer deceleration time in [FA-12] can ease the

insufficient regenerative torque.

• When regenerative torque is required, the situation may be

improved by adjusting the manual torque boost function, or

by operating the inverter and making adjustments with con-

trol method in [AA121].

• Re-examination of load condition may improve the situation.

Error occurred right

after an operation

command input.

• A ground fault has

occurred.

• Output line is short-cir-

cuited or in open

phase.

• Output element failure

• The inverter may be broken if the error persists even when

the power of inverter only is turned ON again after the power

was turned OFF and the output line to the motor was

removed.

• If the issue is solved when the output line to the motor is

removed, you need to check the wiring and/or motor.

• Motor is locked.

• Load inertia is large.

• Error may occur when the motor rotation is locked.

• The situation may be improved by taking a measure for the

case “Error occurred during acceleration”.

Error occurred right

after power was

turned ON.

• Output element failure

• Current detector fail-

ure

Failure output element or current detector may be the cause.

An investigation and repair are required.

Error occurred after

long hours of use.

System environment

changes

The situation may be improved by reducing the motor load, or

performing a system maintenance (e.g., cleaning the fan to be

driven and removing clogging in the duct).

Aging deterioration

If the issue is not solved by reduction of the load and system

maintenance, aging deterioration of a life-limited

component

may be the cause. A repair is required.

Loading...

Loading...