7 - 59

7 Advanced Settings

High-function General-purpose Inverter RX2 Series User’s Manual

7-4 Reduction of Motor Noise, Noise and Inverter Heat Generation

7

7-4-1 Carrier Frequency

7-4 Reduction of Motor Noise, Noise and

Inverter Heat Generation

The electromagnetic noise from the motor, noise from the inverter and the heat generation in the

inverter can be reduced/suppressed when you change the carrier frequency.

The carrier frequency is the frequency at which the element that controls the inverter output changes.

The carrier frequency can be changed using the [bb101] setting.

It is also effective in avoiding resonance of mechanical systems and motors.

Precautions for Correct Use

• With the selection using [Ub-03] Load specifications, the carrier frequency setting will be

automatically restrained.

• In accordance with the figures of Derating of Rated Output Current on page 2-10, operate the

inverter within the proper current range.

• If the [AA121] control method selection when driven by induction motor (IM) is automatic

torque boost (03), sensorless vector control (08), or zero speed area sensorless vector con-

trol (09), set the carrier frequency to 2.0 kHz or higher.

• If the [AA121] control method selection is the synchronous motor/permanent magnet motor

(SM/PMM) sensorless vector control (11), set the carrier frequency to 8.0 kHz or higher.

• The carrier frequency should be set to 10 times or higher of the [Hb105] IM highest frequency

or [Hd105] SM (PMM) highest frequency.

(Ex.) When [Hb105] = 60 Hz, [bb101] = 0.6 kHz (600 Hz) or higher

• When using the carrier frequency of 2.1 kHz or higher, see 2-1-3 Installation Environment on

page 2-7.

7-4-1 Carrier Frequency

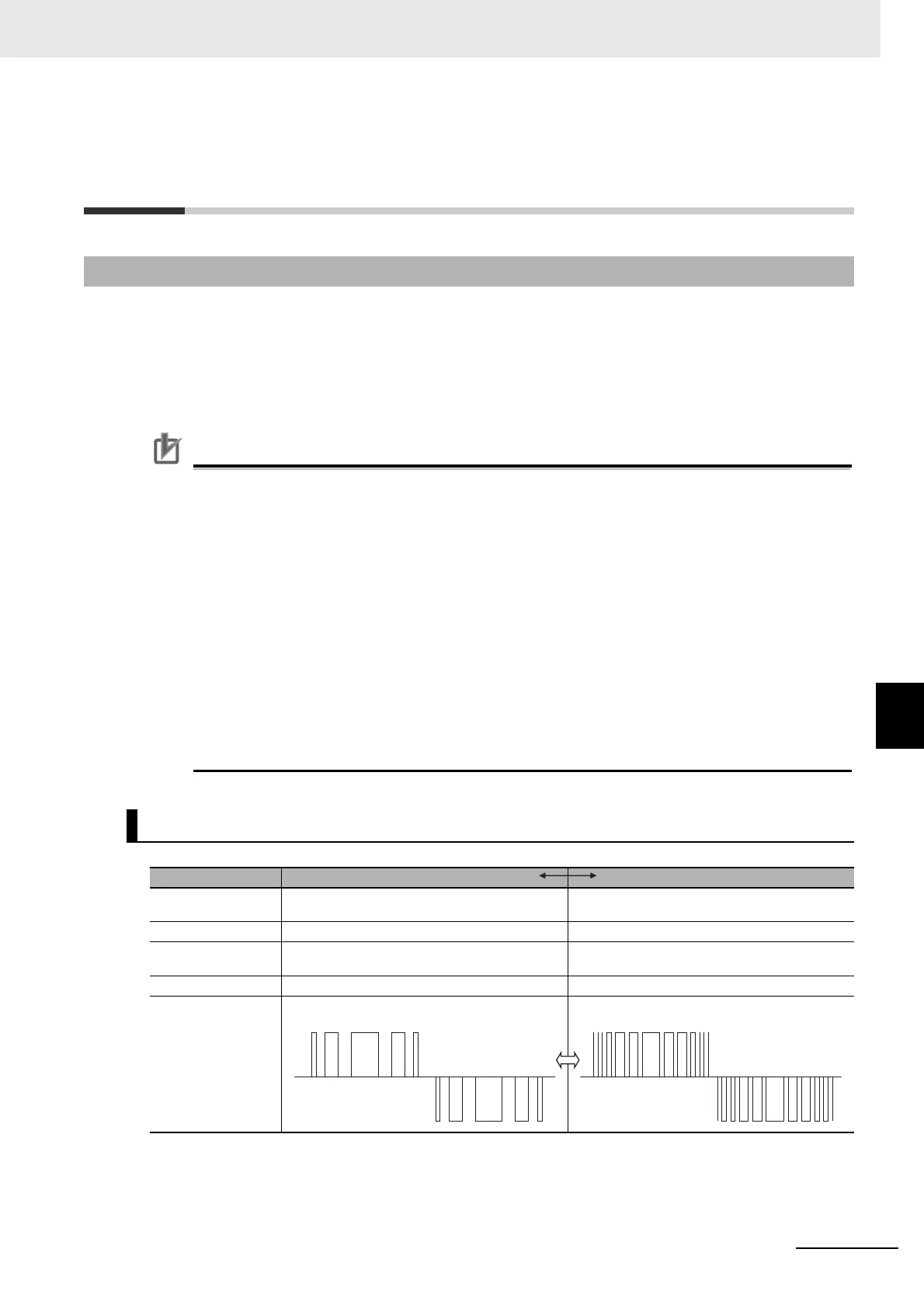

Carrier Frequency and Its Extent of the Effect

Carrier frequency Low High

Motor electromag-

netic noise

Loud Quiet

Noise Quiet Loud

Inverter heat gen-

eration

Little Great

Leakage current Low High

Inverter output volt-

age waveform

example

(PWM output)

Carrier frequency: Low Carrier frequency: High

Loading...

Loading...