SECTION 05: COOLING SYSTEM

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

3. MAINTENANCE

3.1 GENERAL RECOMMANDATIONS

A systematic routine inspection of cooling

system components is essential to ensure

maximum engine and heating system efficiency.

• Check coolant level in the surge/recovery

tank daily, and correct if required. Test

antifreeze strength.

• Check water pump belt and replace if frayed

or badly worn.

• Check radiator cores for leaks and make

sure the cores are not clogged with dirt or

insects. To avoid damaging the fins, clean

cores with a low-pressure air hose. Steam

clean if required.

• Inspect the water pump operation. A leaky

pump sucks in air, increasing corrosion.

• Repair all leaks promptly. Unrepaired leaks

can lead to trouble. Inspect and tighten

radiator mounts periodically. Test and

replace thermostat regularly.

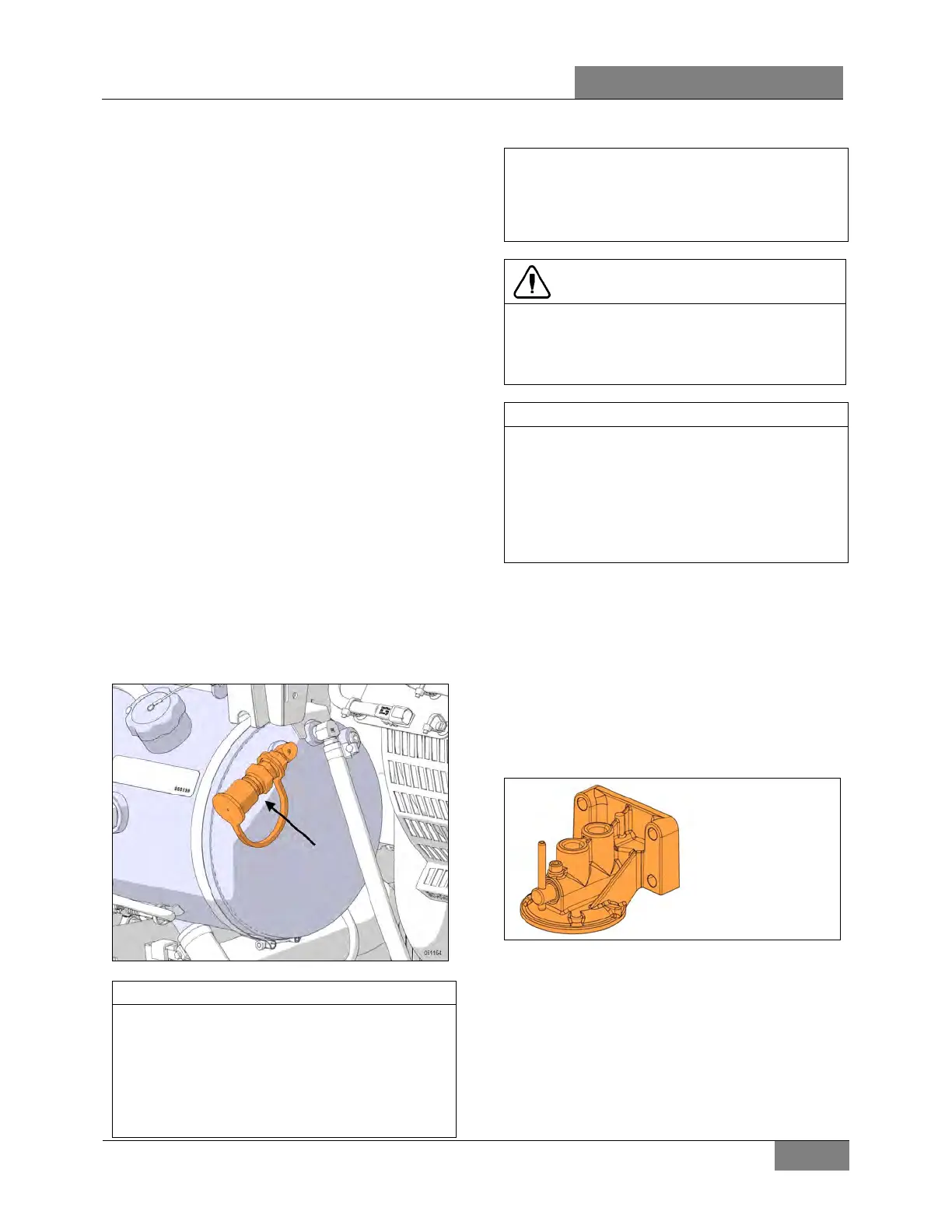

• Pressurize system periodically using Hansen

Quick Coupling (Figure 3).

FIGURE 3: HANSEN QUICK COUPLING

In order to ensure the integrity of the system, it

is recommended that a periodic cooling system

pressure check be made. Pressurize the

cooling system to 10-

Quick Coupling. Do not exceed 15 psi.

Any measurable drop in pressure may indicate

a leak. Whenever the oil pan is removed, the

cooling system should be pressure checked as

a means of identifying any incipient coolant

leaks. Make sure the cause of the internal leak

has been corrected before

contaminated system.

CAUTION

Hoses and hose connections should be clean

and free of oil and grease before hose clamp

installation. Do not use

sealing compound on hose connections.

For additional information conc

D13 engine components or engine-related

components, consult Volvo Trucks North

America Web site under: Parts & Service. On

Volvo web site, you will find detailed service

procedures for parts replacement, repair and

maintenance.

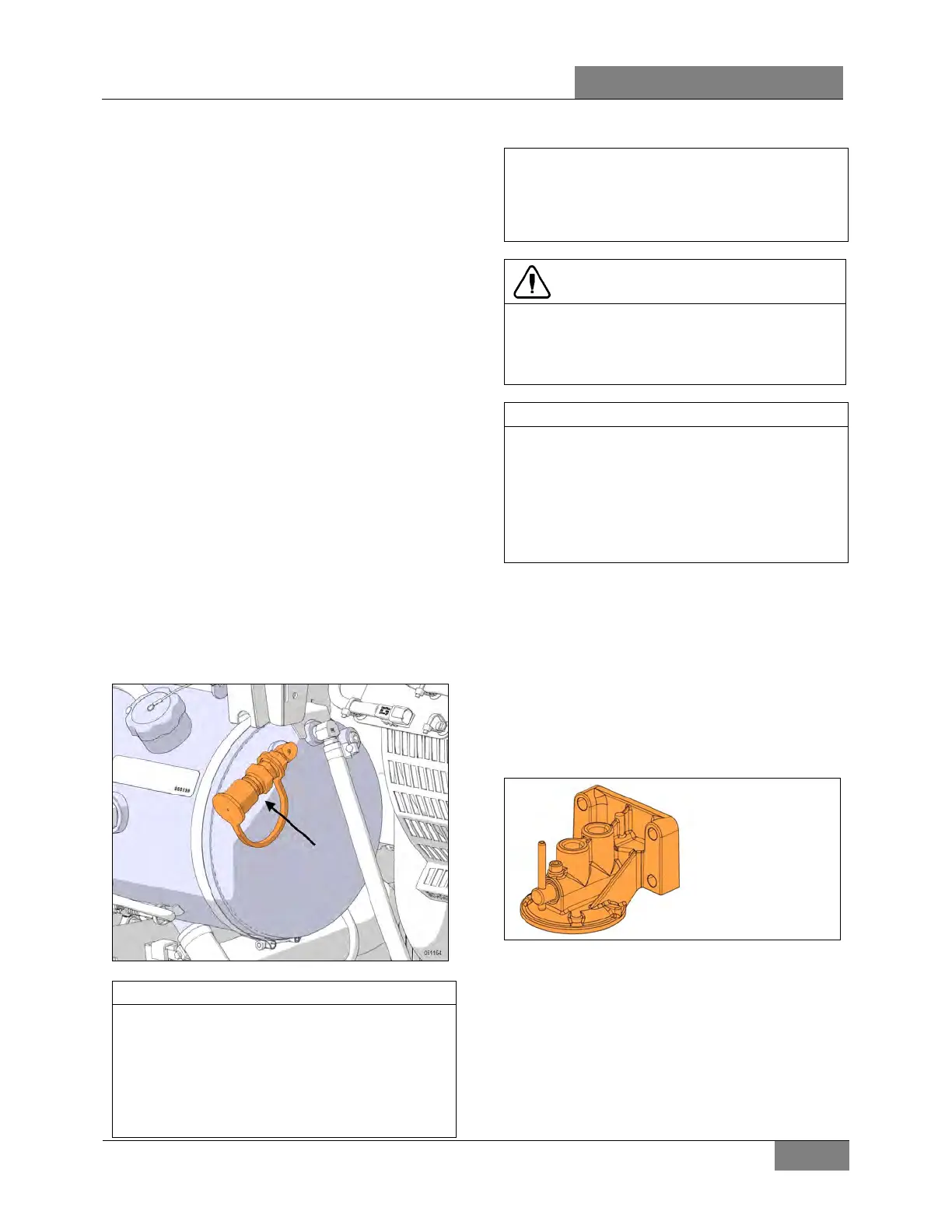

3.2 COOLANT FILTER HOUSING SHUT-

OFF VALVE – SPINDLE SERVICING

Seizing of the spindle in the coolant filter housing

(Figure 4) could prevent proper operation of the

valve. With proper cleaning, the application of a

silicone-based lubricant to the groove in the

spindle, and cycling the valve at regular intervals

will prevent the buildup of corrosion in the

coolant filter housing. Follow this spindle

servicing and repair procedure.

FIGURE 4: COOLANT FILTER HOUSING

1. Park the vehicle on a level surface. Apply the

parking brake and place the transmission in

neutral.

2. Turn the ignition switch to the OFF position.

3. On the engine compartment rear start panel

(Figure 5), push the engine stop/ignition

interlock button to prevent the engine from

being started.

Loading...

Loading...