SECTION 12: BRAKE AND AIR SYSTEM

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 12 revised Jan 2021

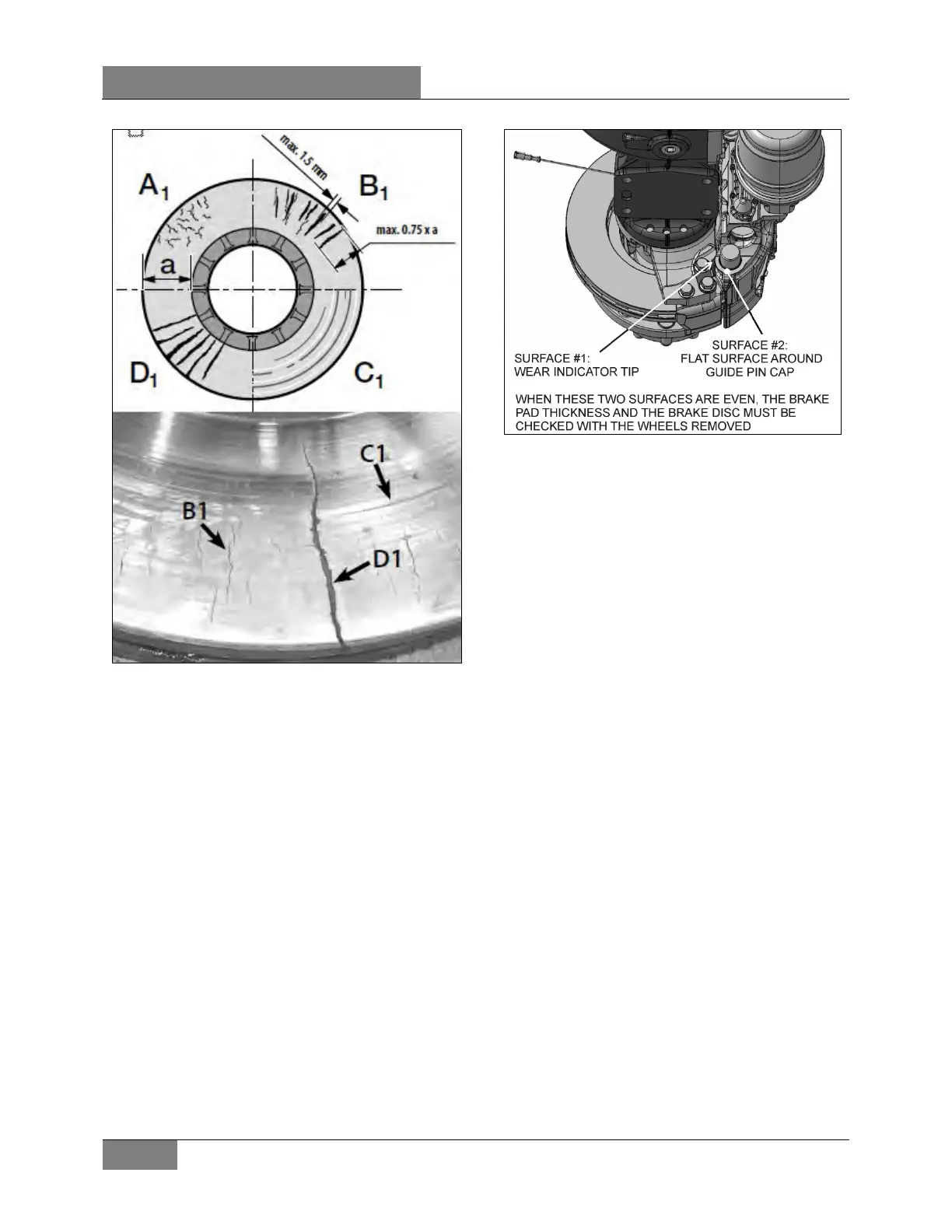

FIGURE 35: TOLERANCES AND EXAMPLES OF CRACKS

AND GROOVES

16.2.3 Wear Check of Pad/Disc –Drive Axle –

Equipped With L-bracket Wear

Indicator

The condition of the pad/disc can quickly be

checked without removing the wheel by

checking the position of the caliper compared to

the tip of the wear indicator.

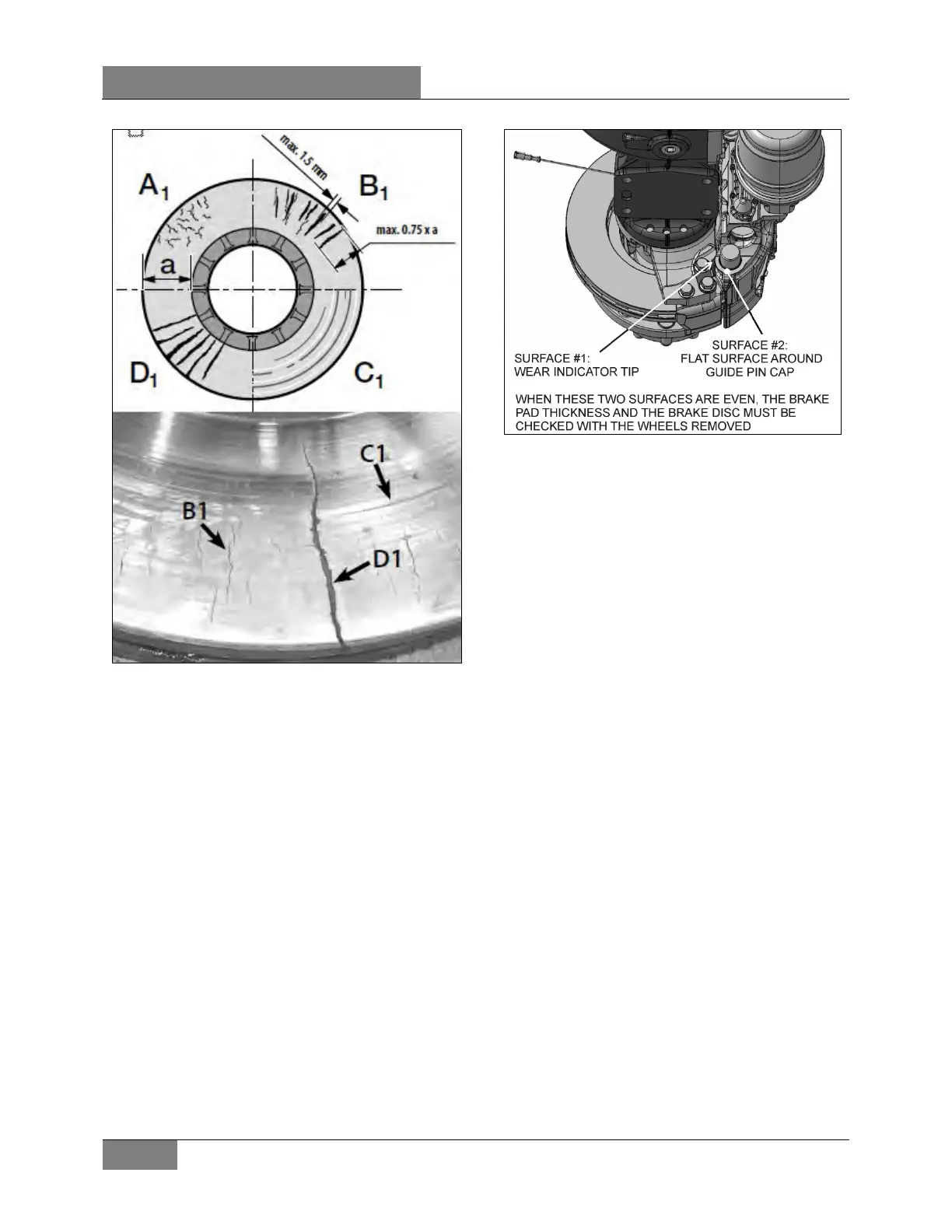

FIGURE 36: BRAKE PAD WEAR CHECK ON DRIVE AXLE

16.2.4 Wear Check of Pads/Disc – Front and

Tag Axle – Equipped With Visual Wear

Indicator

The condition of the pads can be checked

without removing the wheel by checking the

position of the caliper compared to the tip of the

wear indicator or carrier depending on vehicles.

In one variant of the visual wear indicator

(Figure 36), if the side of the caliper (flat surface

around guide pin cap) lines up with the tip of the

wear indicator (i.e. measurement A would be 0.0

in), the brake pad thickness and the brake disc

must be checked with the wheel removed. If any

minimal tolerance limits have been reached, the

pads and/or disc must be changed.

Alternately, brake pad wear can be checked

using carrier to caliper position. When points “P”

and “R” align the brake pad thickness and brake

disc must be checked with the wheels removed

(FIGURE 38). If any minimal tolerance limits

have been reached, the pads and/or disc must

be changed.

Refer to Knorr-Bremse Pneumatic Disc Brake

Y006471 Service.

Loading...

Loading...