DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

3.5 FLUID AND FILTER CHANGE

PROCEDURE

3.5.1 Drain

1. The transmission should be at an operating

temperature of 160ºF (71ºC) to 200ºF (93ºC)

when the fluid is drained. This will ensure

quicker and more complete fluid drainage.

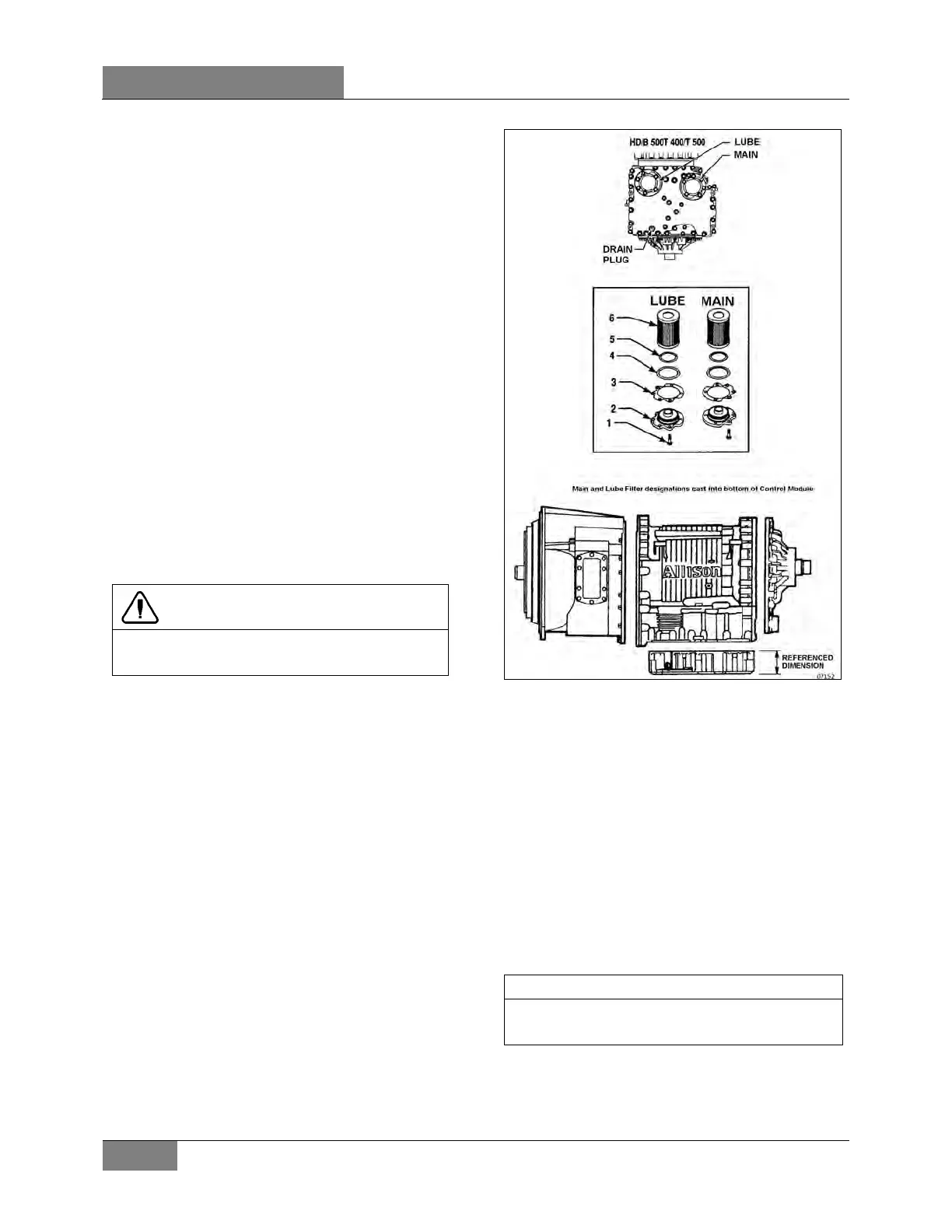

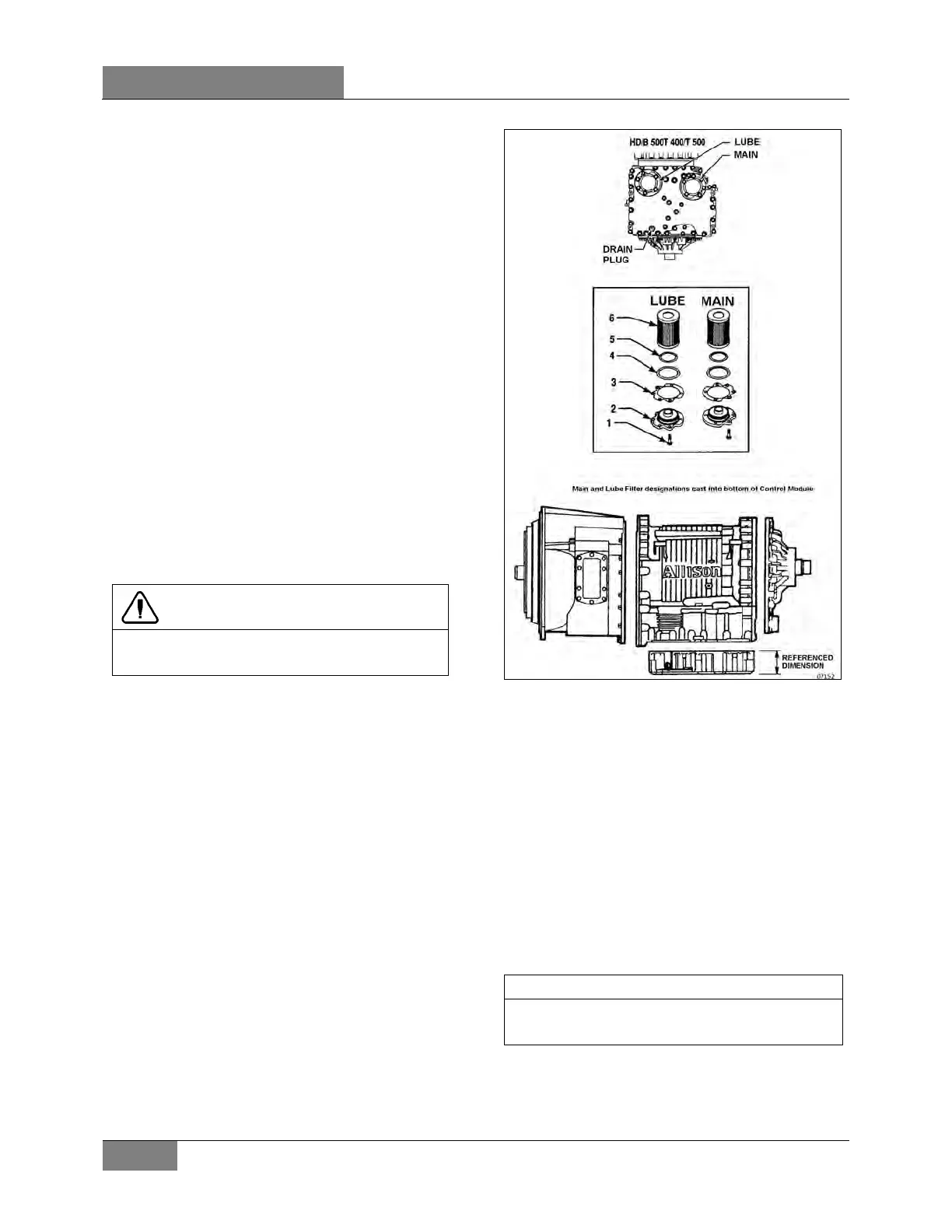

2. Remove the drain plug from under the

transmission (Figure 6) and allow the fluid to

drain into a suitable container. Check the

condition of the fluid as described previously.

3. Remove twelve bolts (item 1), two filter covers

(item 2), two gaskets (item 3), two O-rings

(item 4), two O-rings (item 5) and the two filters

(item 6) from the bottom of the control module

(Figure 6).

4. When reinstalling parts, lubricate and install

new O-rings (4) and (5) on each cover (2).

Lubricate O-ring inside filter (6) and push filter

onto cover (2). Install new gaskets (3) on

cover (2) and align holes in gaskets with holes

in cover.

CAUTION

Do not use bolts to draw the cover to sump.

This can damage the cover, seal, or sump.

5. Install filter and cover assemblies into the filter

compartment. Align each filter/cover

assembly with the holes in the channel

plate/sump. Push the cover assemblies in by

hand to seat the seals.

6. Install twelve bolts and both covers.

TORQUE: 38-45 lb-ft (52-61 Nm)

7. Inspect the drain plug and O-ring. Replace if

necessary. Reinstall the drain plug.

TORQUE : 18-24 lb-ft (24-33 Nm)

FIGURE 6: DRAIN PLUG AND FILTERS

Fluid loss with filter change only

When changing main and lube filters at

recommended intervals, approximate fluid loss

for each filter as follows:

Main filter = 2 quarts (1.9 liters)

Lube filter =8 quarts (7.6 liters)

3.5.2 Refill transmission

The amount of refill fluid is less than the amount

used for the initial fill. Fluid remains in the

external circuits and transmission cavities after

draining the transmission.

Quantities listed below are approximations and

do not include external fluid cooler lines.

Loading...

Loading...