SECTION 22: HEATING AND AIR CONDITIONING

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

4. HVAC SYSTEM COMPONENTS

4.1 COMPRESSOR – CENTRAL A/C

SYSTEM

The central system is equipped with a Bitzer

4-cylinder model 4NFCY compressor. Refer to

paragraph 7 “Specifications” at the end of this

section.

For complete information on Bitzer A/C

compressor maintenance, installation, torque

chart, approved oils, refer to the following Bitzer

manuals found on your Technical Publications

USB flash drive and on the Prevost Technical

Publications web site.

• Bitzer kw-540-1 Maintenance Instruction

• Bitzer kb-540-3 Operating Instructions

• Bitzer kw-541-2 Exchanging Shaft Seal

• Bitzer kw-555-3 Tightening Torques

• Bitzer kt-100-3 Capacity Control

(unloader)

• Bitzer ke-540-7 Spare Parts List

• Bitzer kt-510-5 Tech Info oils

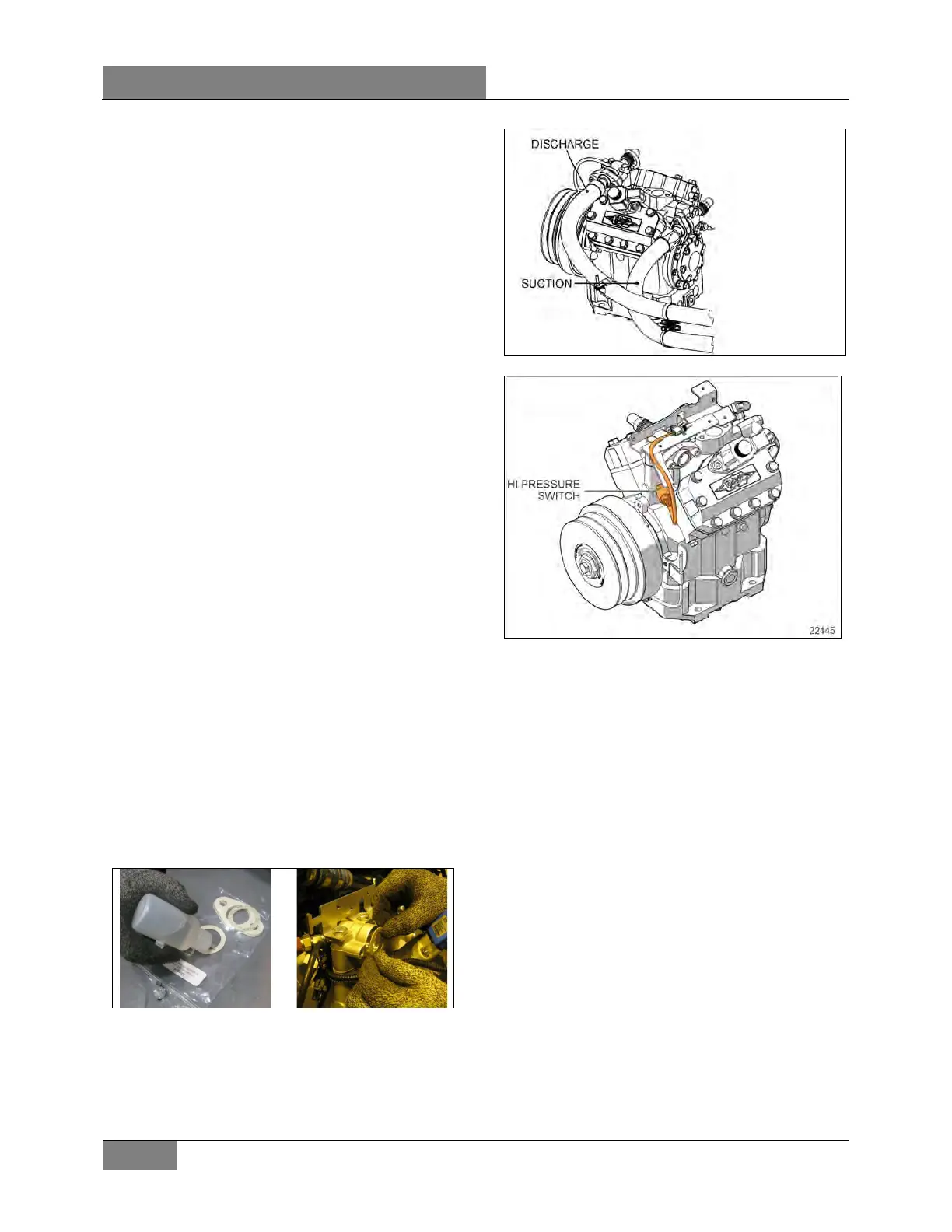

4.1.1 Suction and Discharge Hose

Connection

1. Before connecting suction and discharge

refrigerant hoses to the compressor, apply

POE compressor oil on new gaskets, do not

dip in oil.

2. Tighten hose flange by hand in 2

sequences.

3. Apply a final torque on cap screws.

TORQUE: 31-35 lb-ft (42-47 Nm)

FIGURE 15: SUCTION AND DISCHARGE HOSE

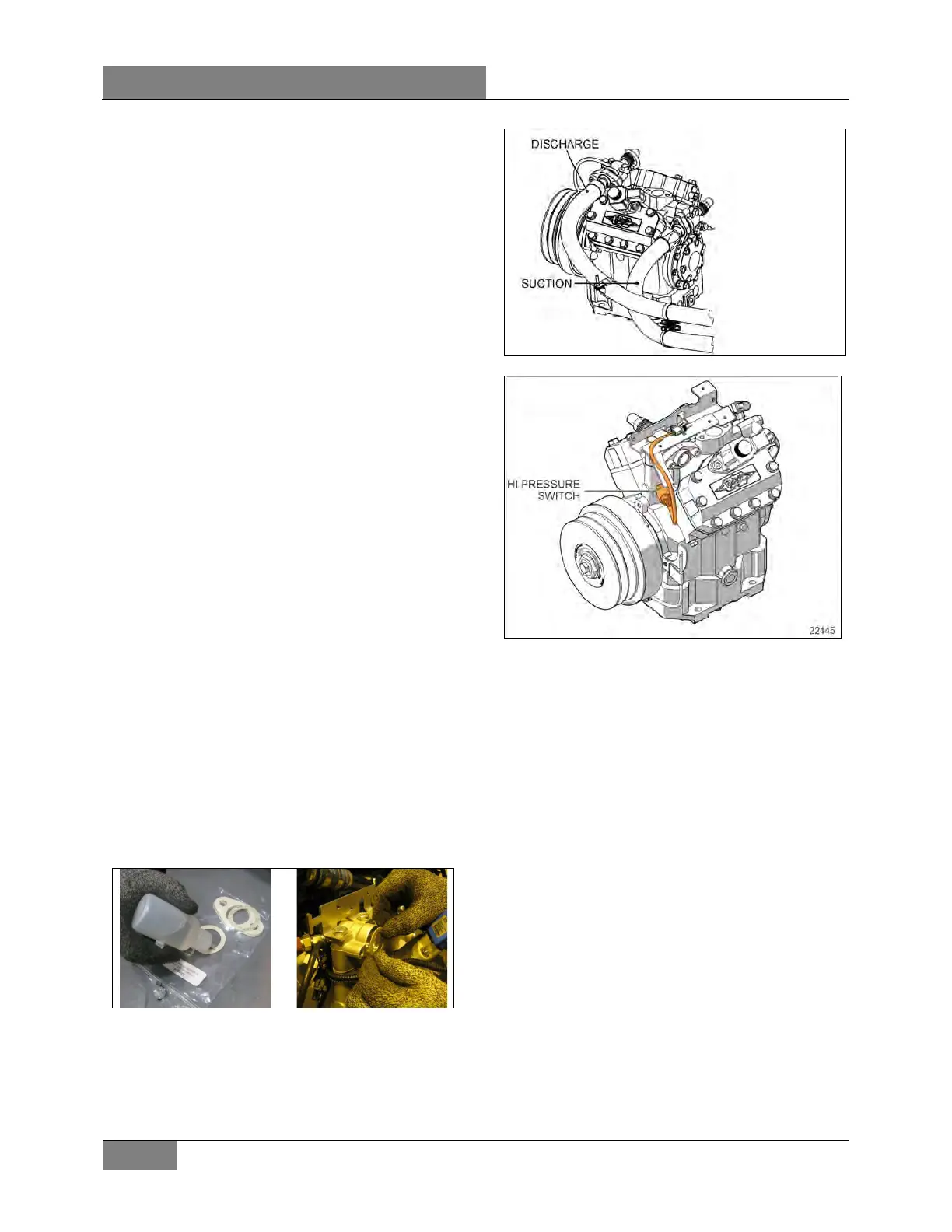

FIGURE 16: BITZER COMPRESSOR

4.1.2 Electro-Magnetic Clutch

For the Lang KK73.1 electromagnetic clutch

removal & installation procedure, refer to

Maintenance Information MI18-37.

For Lang KK73.1 electromagnetic clutch service

manual or bearing replacement procedure, refer

to the following manuals found on your

Technical Publications USB flash drive and on

the Prevost Technical Publications site.

• Lang clutch KK73.1 bearing replacement

• Lang operating instr_KK73 1_2

• Lang Service manual_KK73.1_2

• Bitzer Maintenance Instruction kw-540-1

4.1.3 Maintenance - Shaft Seal Oil

Collecting tube Drain

The shaft seal oil tube collects oil seeping

through the felt shaft seal. Remove the tube plug

and drain the oil into a container for disposal.

Replace the cap on the tube and replace the

tube into the clip bracket.

Loading...

Loading...