DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

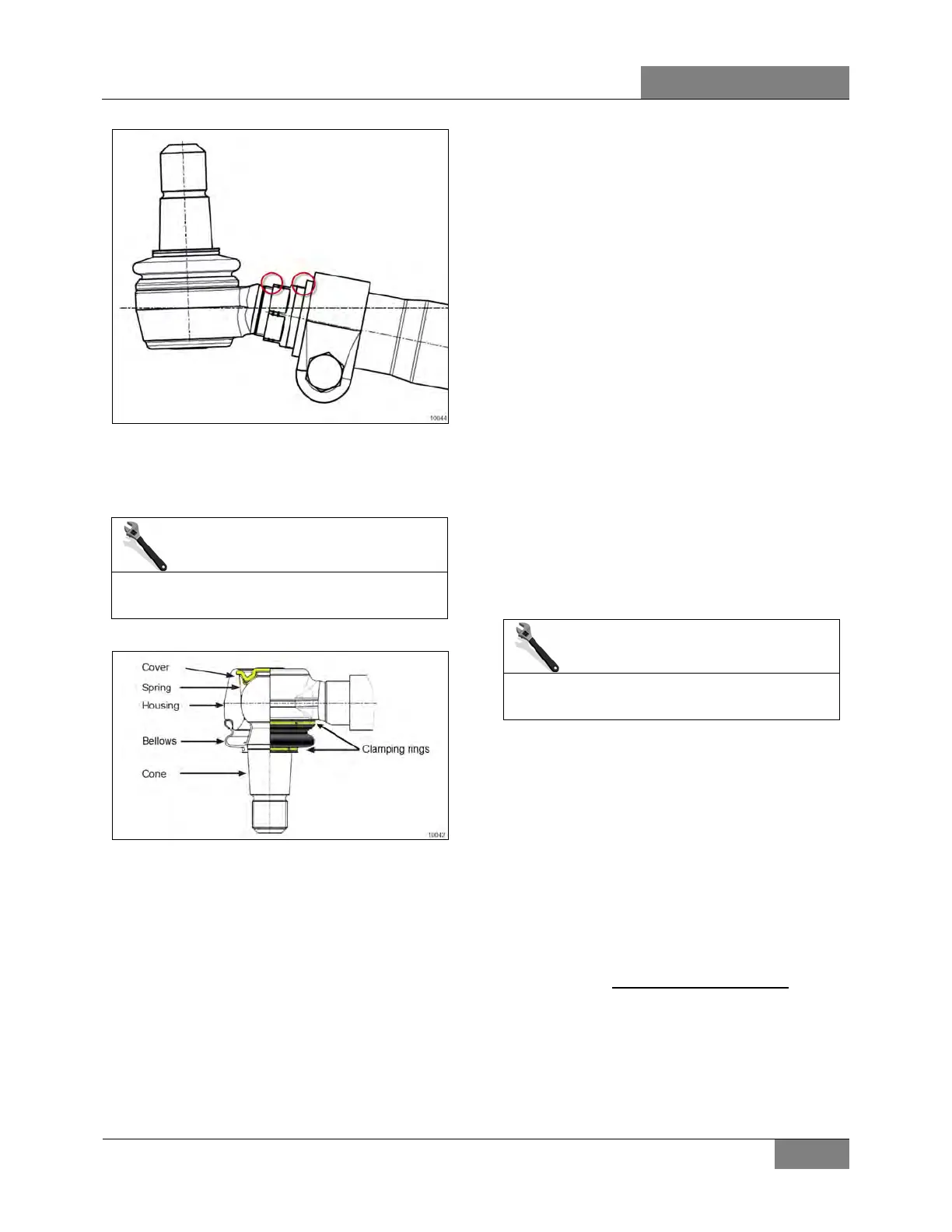

FIGURE 34:

13.8.4 Tie rod ball joint inspection for

corrosion

MAINTENANCE

Inspect tie rod ball joints for corrosion once a

year.

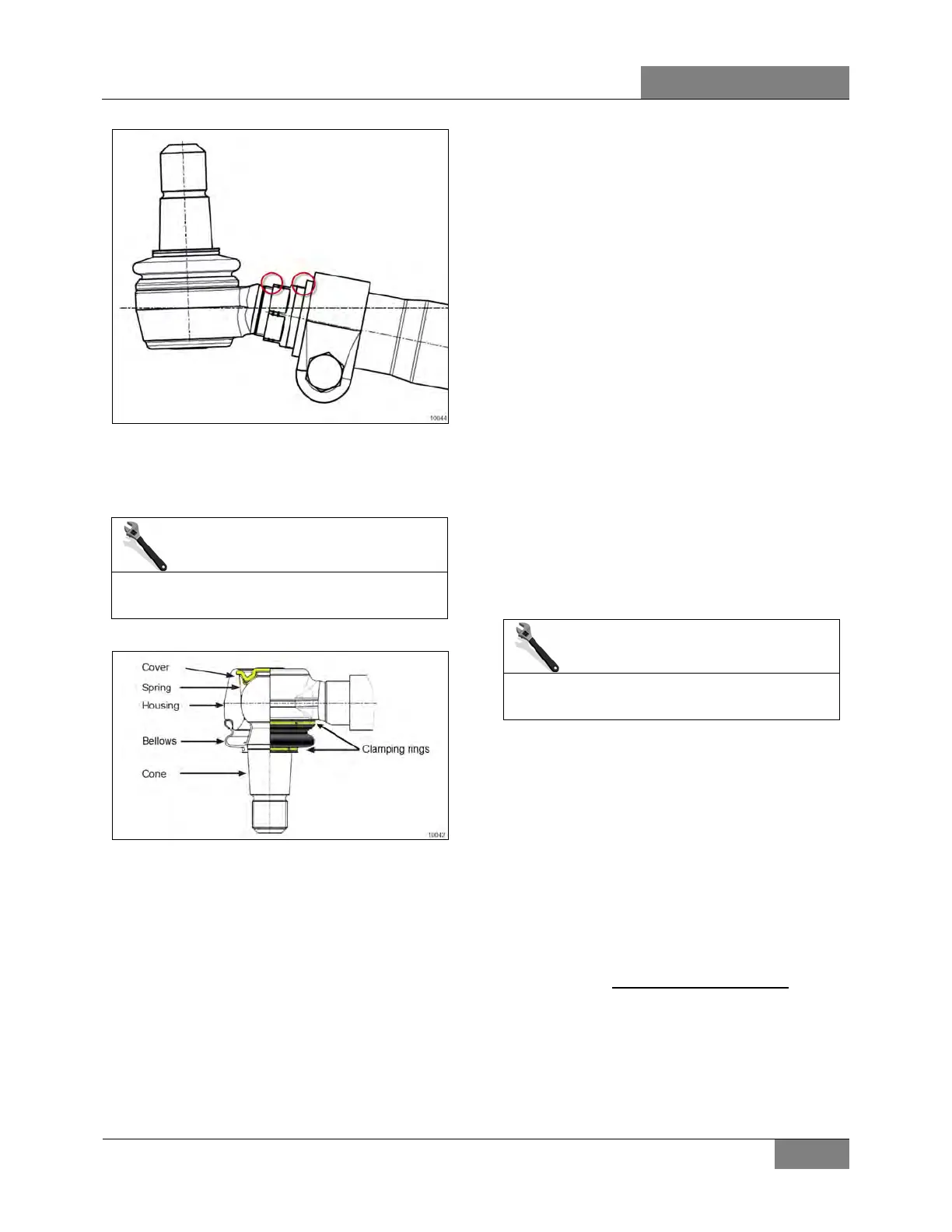

FIGURE 35: TIE ROD BALL JOINT CONSTRUCTION

1. Carefully clean the sealing boot contact area

to ensure that no contaminants can get

under the sealing bellows during the

inspection procedure. Do not use cleaning

agents or solvents, only use dry cloth or

cotton wool.

2. Housing: The housing must not show any

signs of deep rusting (depth of no more than

approx. 1mm). Pay particular attention to the

roll edge and cover, they must be rust free.

Clean corrosion on the axle steering lever

contact faces also.

3. Bellows: They must be in perfect condition

to protect from corrosion. Squeeze the

bellows by hand and make sure no grease is

expelled from the opening. Make sure the

bellows is in good condition, without any

holes, tears, scratches of chafing marks.

Replace the joint if inspection result is not

OK.

Tension rings and clamping rings must be

well seated in their groove.

It must always be possible to turn the

bellows on the housing by hand (do not use

any tools). Hold the bellows in the area of

the clamping ring and turn with a lot of

manual force. Replace the tie rod if the result

is not OK.

13.9 DRAG LINK BALL JOINT INSPECTION

FOR CORROSION

Inspection of ball joints is important. Damaged

sealing boots, salt and climatic conditions can

cause loss of the corrosion protection coating

applied at time of manufacturing.

MAINTENANCE

Inspect drag link joints for corrosion once a

year.

1. Carefully clean the sealing boot or dirt seal

contact area to ensure that no contaminants

can get under the sealing boot or dirt seal

during the inspection procedure. Do not use

cleaning agents or solvents, only use dry

cloth or cotton wool.

2. Use an appropriate inspection tool (e.g.

spatula with cut out) to push up (sealing

boot) or down (dirt seal) the seal (without

damaging it) until ball pin surface is visible.

Degrease the ball pin surface and inspect

carefully.

3. If there is corrosion of the ball pin or the

sealing boot has deteriorated through

ageing or is damaged, replace the ball joint.

4. If there is corrosion of the steering arm or tie

rod arm area which is in contact with the

sealing boot or dirt seal, clean and eliminate

all surface irregularities.

Loading...

Loading...