DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

2. DESCRIPTION

The vehicle is provided with an air suspension

system. The system consists of air springs,

height control valves, radius rods, sway bars,

tripod and shock absorbers (Figure 1 to Figure

7). The system operation is fully automatic and

maintains a constant vehicle height regardless of

load, or load distribution.

The vehicle is also equipped with front kneeling

function to quickly lower the front end.

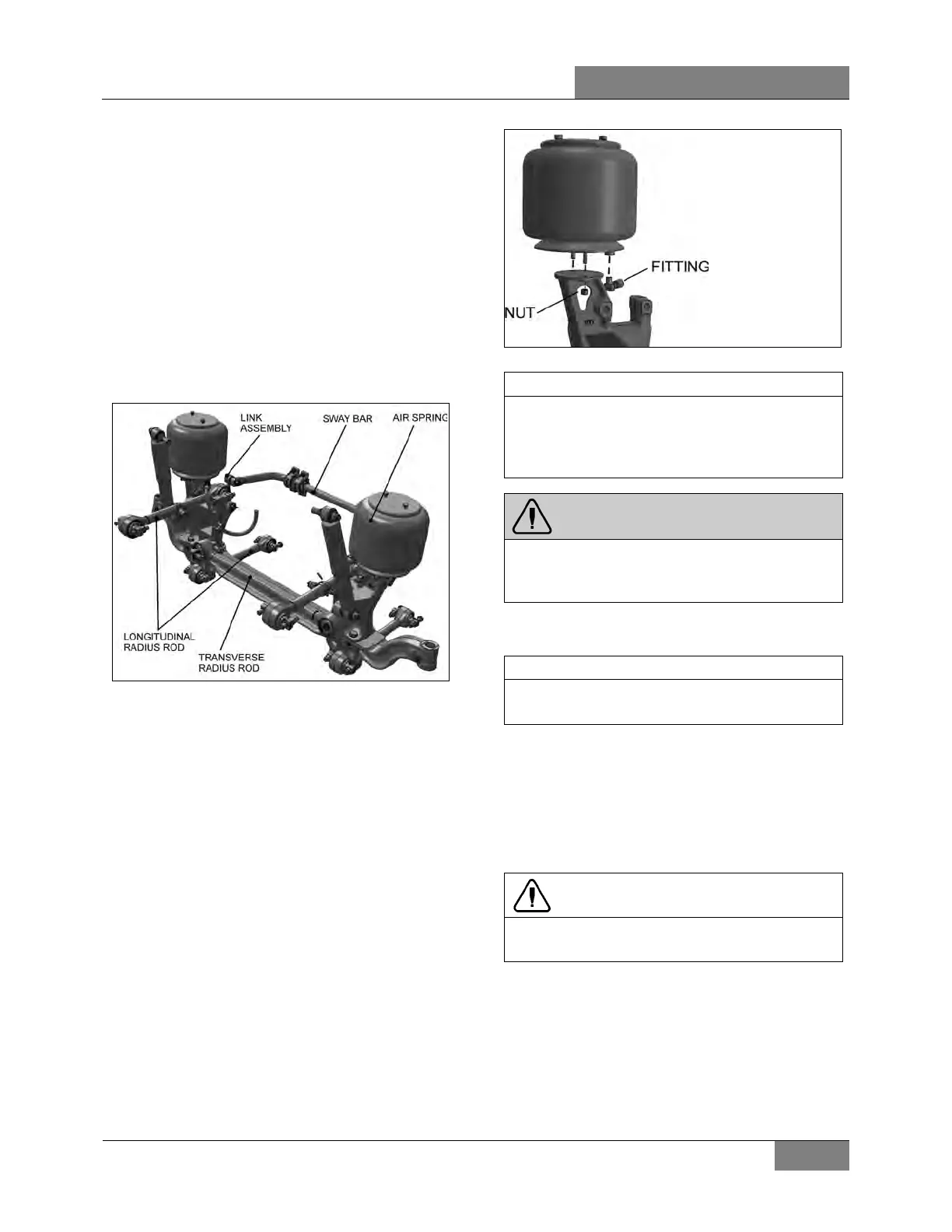

3. FRONT I-BEAM AXLE SUSPENSION

FIGURE 1: FRONT I-BEAM AXLE SUSPENSION 16105

3.1 AIR SPRINGS

The air spring bellows are made from a special

compound rubber molded to the proper contour

and dimensions. The entire vertical load of the

vehicle is supported by these springs. Each of

the three axles is provided with air springs that

are attached to the subframe and to the axles.

3.1.1 Inspection

1. Check operation of bellows.

2. Visually inspect bellows for evidence of

cracks, punctures, deterioration, or chafing.

Replace the bellows if any damage is

evident.

3. With the primary air system at normal

operating pressure (122 - 140 psi (841 - 965

kPa)), coat all suspension air line

connections and bellows mounting areas

with a water and soap solution. Bubbles will

indicate an air leak, and none is permissible.

Repair or replace defective parts.

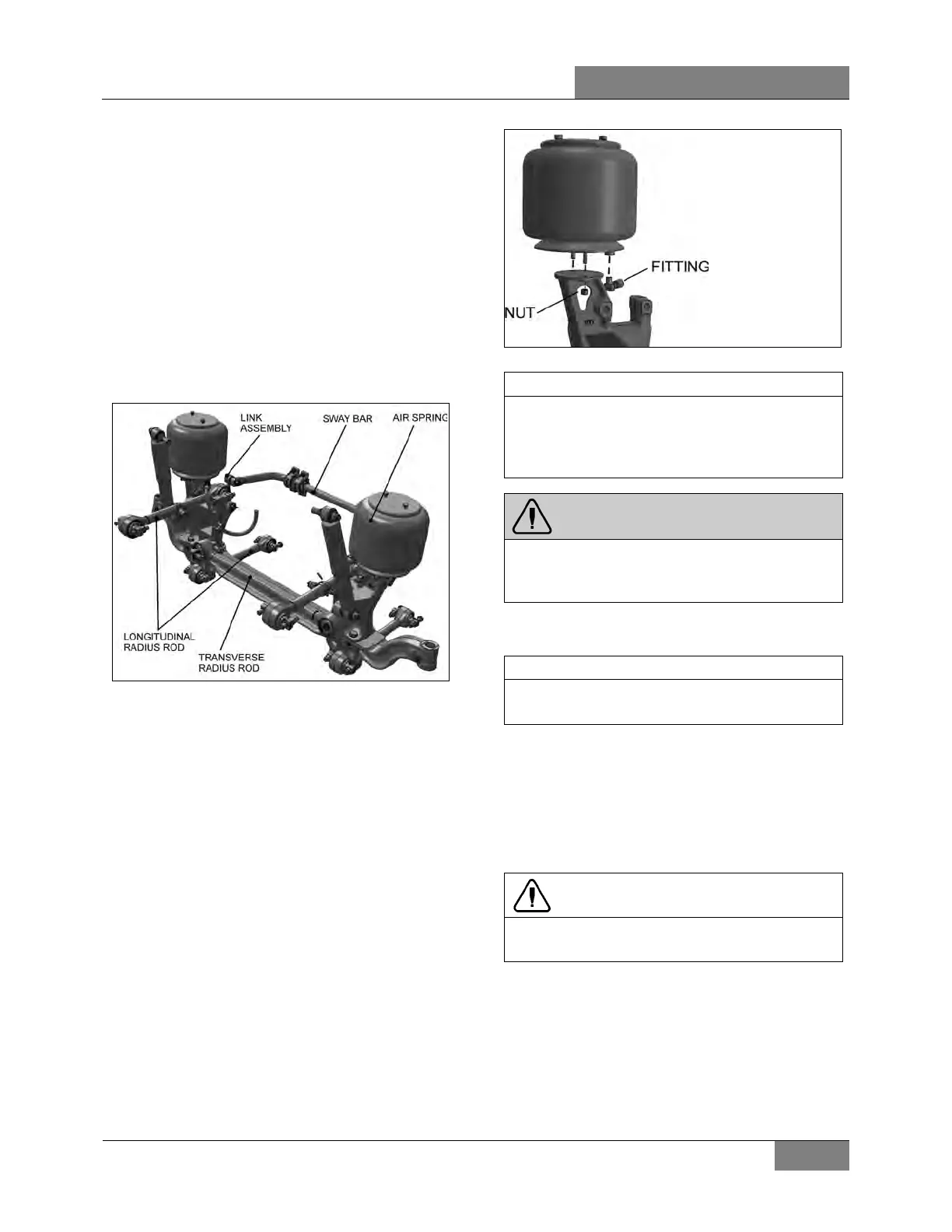

FIGURE 2: AIR SPRING 16052

If air spring is removed from vehicle, bellows

can be lightly inflated and submerged in water

to detect any leak

detected, replace bellows.

WARNING

To prevent personal injury, do not apply more

than 10 psi (69 kPa) of air pressure to the

uninstalled air spring.

3.1.2 Removal

Front suspension air springs can be removed

without removing the entire axle assembly.

1. Safely support vehicle at the recommended

body jacking points. To gain access to a

given air spring, the corresponding wheel

can be removed as follows:

a) Jack vehicle until the tire clears the

ground, and place safety supports

underneath body.

CAUTION

Only the recommended jacking points must be

used as outlined in Section 18, “Body”.

b) Support the axle with a suitable

hydraulic floor jack at the

recommended jacking points. Make

sure that the measurement between

the air spring mounting plates is

greater than the normal clearance

(normal ride height).

c) Remove wheel.

Loading...

Loading...