DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

3 POWER STEERING GEAR

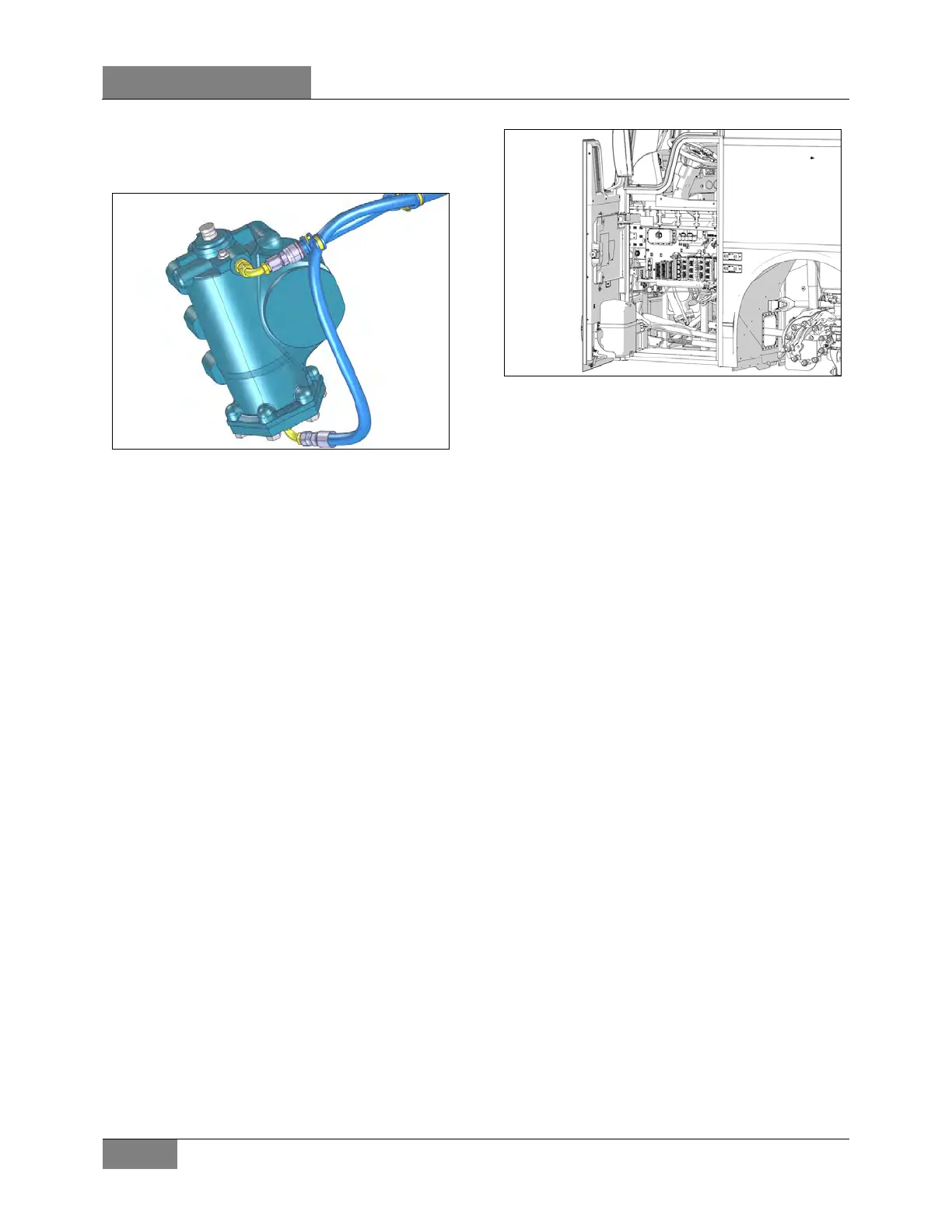

FIGURE 2: POWER STEERING GEAR 14035

3.1 DESCRIPTION

The power steering gear is located in the lower

part of front service compartment (Figs. 3 & 4).

The housing of the ZF/Robert Bosch-Servocom

contains a control valve, working cylinder and a

complete mechanical steering gear. The

pressure oil for the steering is delivered by a

motor-driven oil pump which is supplied with oil

from an oil tank.

The housing is designed as a cylinder for the

piston, which converts the rotation of the

steering shaft and the worm into an axial

movement and transfers this to the steering

worm sector shaft. The serration of the sector

shaft is straight-cut with a high surface quality in

such a way that it is only possible to set a

unique setting without play on installation in the

straight-ahead driving area by means of the two

eccentrically designed lateral housing covers.

The piston and worm are connected via a ball

chain. When the worm is turned, the balls are

collected by a circulating pipe at one end of the

chain and fed in again at the other end, thus

producing an endless ball chain.

The control valve consists of the valve slide in a

needle bearing in the worm, with six control

grooves on the circumference and the control

sleeve on the worm, which also has six control

grooves. The valve slide, designed with steering

shaft connection, turns together with the worm

as the steering wheel is turned.

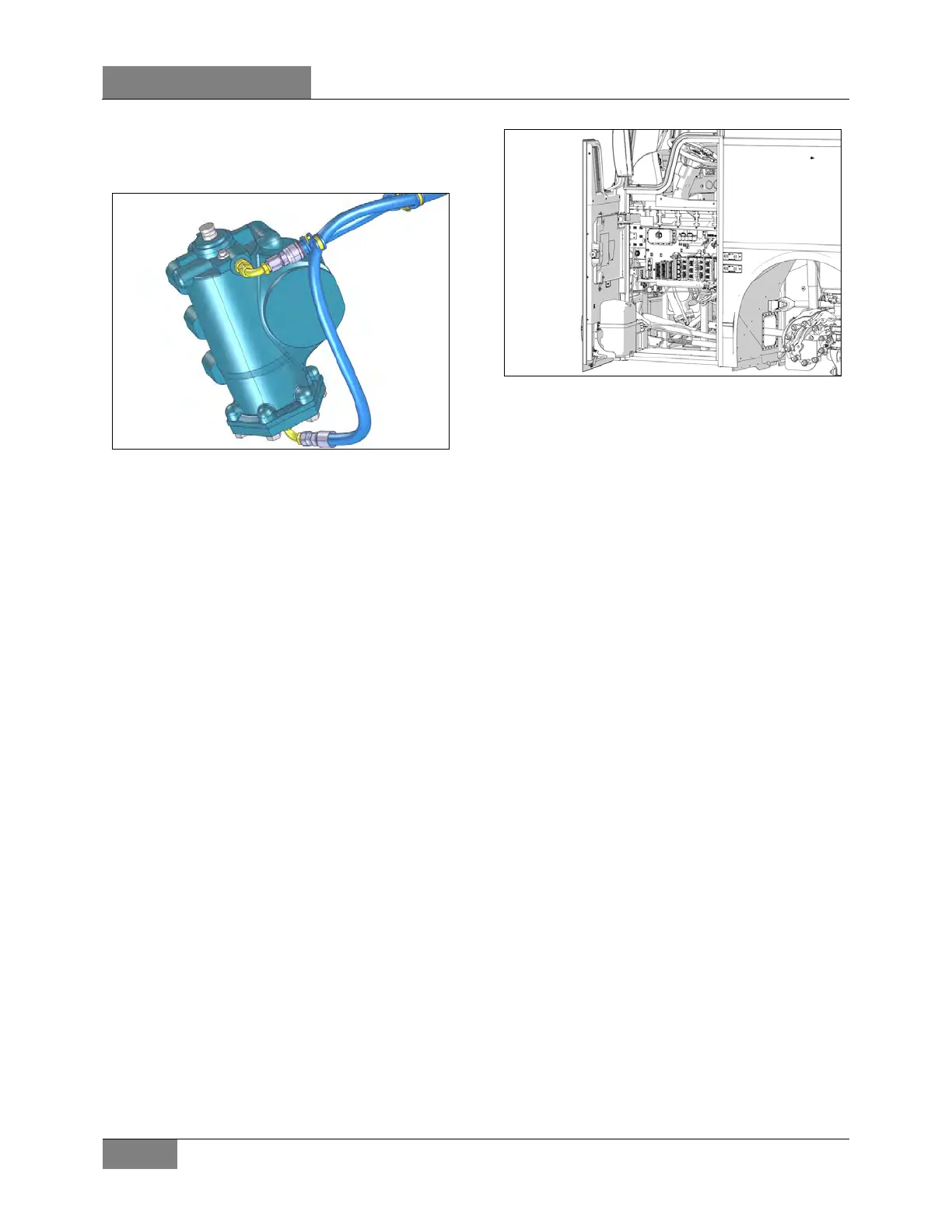

FIGURE 3: FRONT SERVICE COMPARTMENT 18611

A torsion bar, which is pinned with the valve slide

and the worm, keeps the control valve in the

neutral position as long as no opposing force is

applied to the steering wheel. The steering

housing contains a pressure relief valve, which

limits the discharge pressure of the oil pump to

the maximum value required. A replenishing

valve can also be used, through which oil is

sucked from the return if steering is not

hydraulically boosted.

Compared with constant ratio, steering versions

with variable ratio are more directly designed in

the center area than outside the center area. The

resulting smaller steering corrections benefit

steering behavior in straight-ahead driving. At the

same time, the indirect transmission means that

there is a higher hydraulic torque available at the

steering arm in parking movement. If the

hydraulic assistance fails, the operating forces on

the steering wheel are correspondingly lower in

this area. This is achieved through a

piston/steering worm sector shaft serration with

differing modulus and angle of pressure.

Upon transfer of a torque from the steering shaft

to the worm, or vice versa, the torsion bar is

deformed in the elastic area so that there is

torsion between the valve slide and the control

sleeve. When the steering wheel is released, the

torsion bar ensures that the valve is returned to

the neutral position.

Refer to the "ZF-SERVOCOM Repair Manual"

and “RB Robert Bosch Servocom - Service

Manual (8090)”, found on your Technical

Publications USB flash drive, for the

functional aspects and maintenance

procedure of the steering gear.

Loading...

Loading...