SECTION 09: PROPELLER SHAFT

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

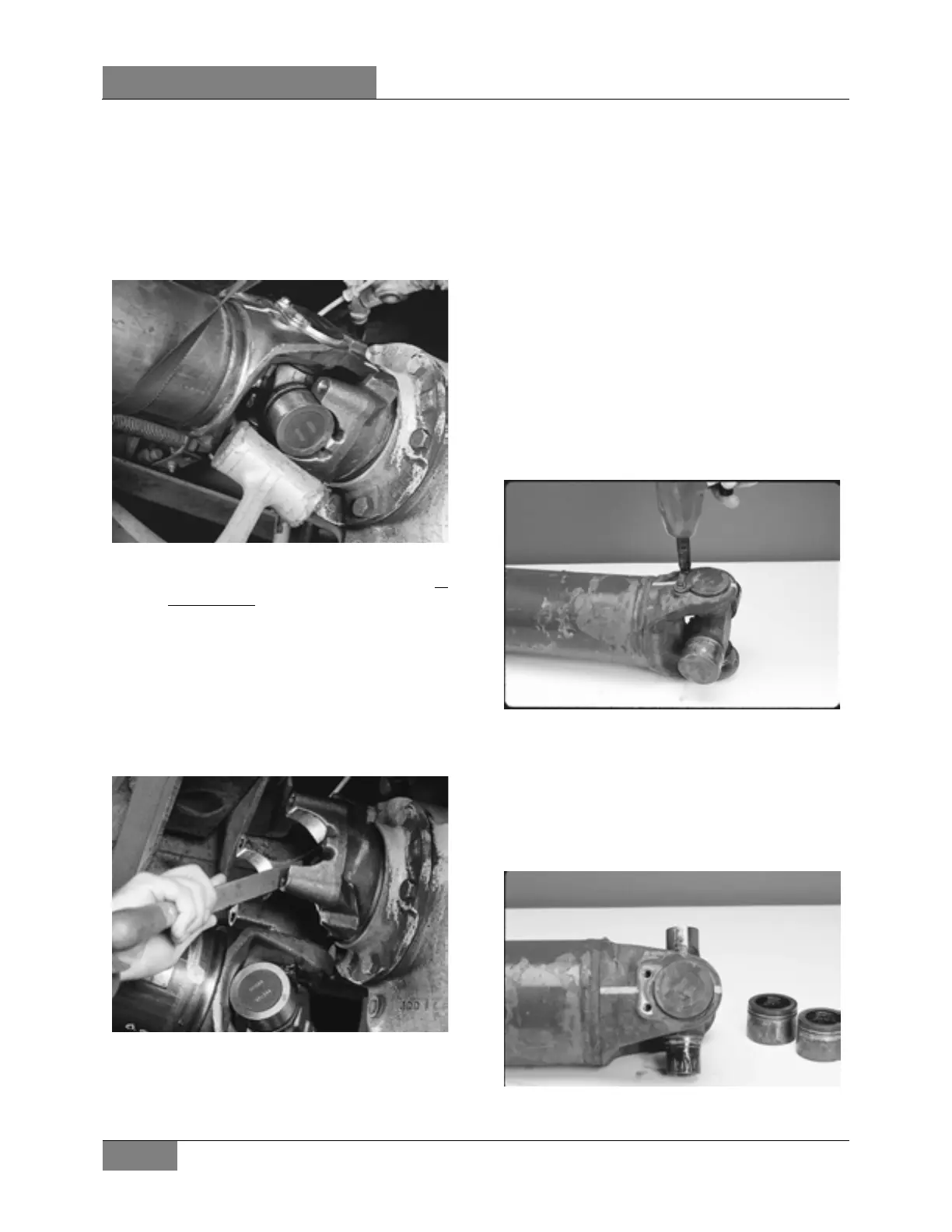

4. It may be necessary to unseat bearing

cup assemblies by tapping on yoke or

bearing cup with a soft-faced hammer.

Once the bearing cup assemblies are

free, collapse the propeller shaft until

both bearing assemblies clear the open

end yoke cross holes. Allow the

propeller shaft to rest on support strap.

FIGURE 13: UNSEATING BEARING CUP ASSEMBLIES

5. Remove bearing retainers and bolts at

the front end.

6. Inspect all end yoke cross hole surfaces

and bolt hole threads for damage. If the

bolt hole threads are damaged, the yoke

must be replaced.

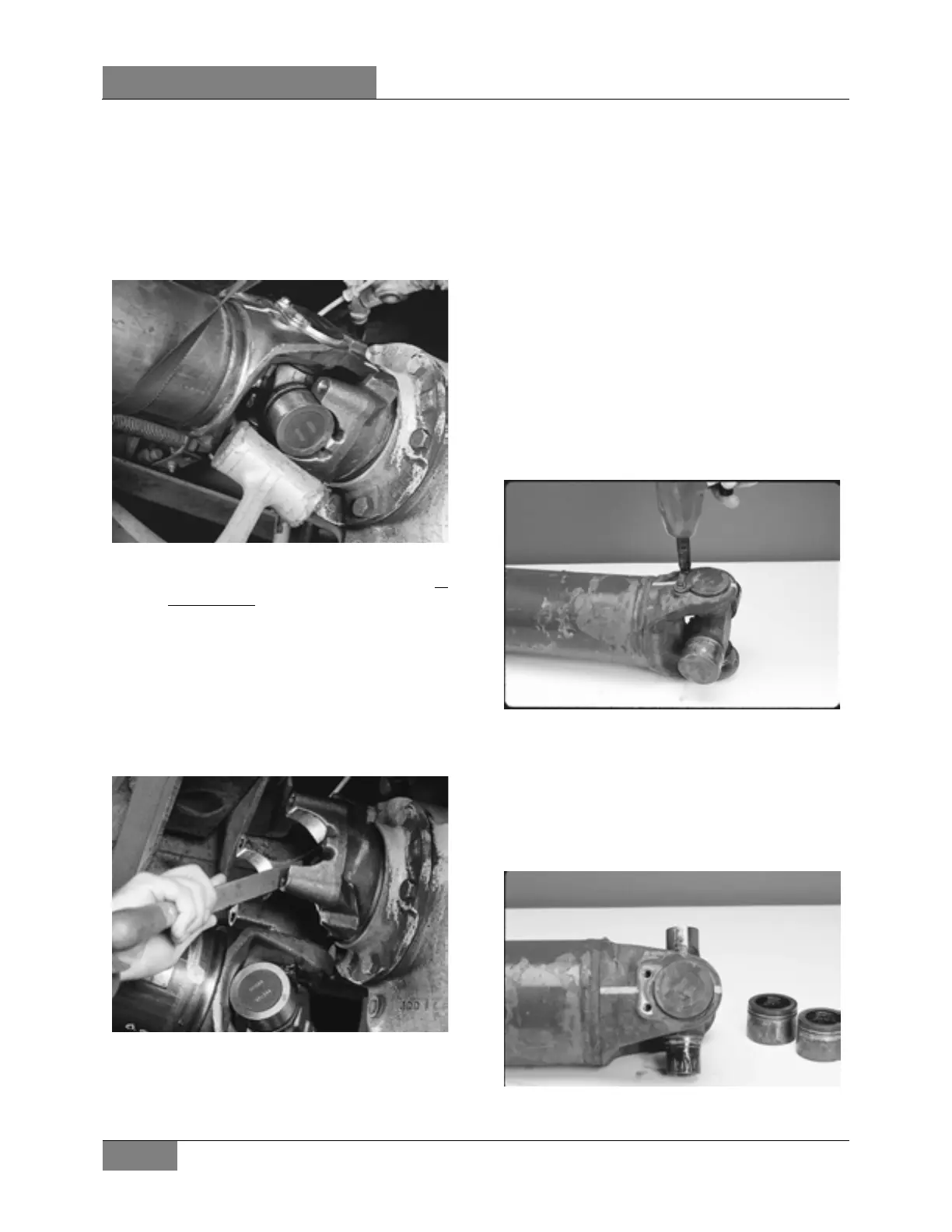

7. Inspect for raised metal or fretting on

open yoke cross holes can be removed

with a fine-toothed file and/or emery

cloth.

FIGURE 14: RAISED METAL OR FRETTING ON OPEN

YOKE CROSS HOLES

8. Inspect the end yoke cross holes for

distortion and damage.

5.1.1 Inspect Companion Flange/Flange

Yokes

1. Inspect all flange bolt hole threads or

through holes for damage. If the bolt

hole threads or through holes are

damaged, the flange must be replaced.

2. Inspect all flange faces for galling or

damage. If damaged, the flange must be

replaced.

5.2 REMOVAL PROCEDURE FOR

UNIVERSAL JOINT KIT

1. For Quick Disconnect Style: Remove

spring tab bolts and discard, and remove

outboard bearing cap assemblies.

FIGURE 15: SPRING TAB BOLTS REMOVAL

2. Make sure universal joints cross assembly is

not tilted in the yoke. Place bearing cup

spacer onto the base of the arbor press and

under the yoke. If the arbor is larger than the

bearing cup diameter, a smaller diameter

push rod will be needed to avoid damaging

the yoke or bearing.

FIGURE 16: CORRECT POSITIONING

Loading...

Loading...