DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 01 revised Jan 2021

4. AUTOMATIC BELT TENSIONERS AND

IDLER PULLEY INSPECTION

With the engine running, if noise is coming from

the tensioners or drive system, an inspection

with the engine off is necessary.

MAINTENANCE

Remove belts and insp

tensioners, idler pulley bearings

at the

intervals specified by the Lubrication And

Servicing Schedule in

LUBRICATION & SERVICING SCHEDULE.

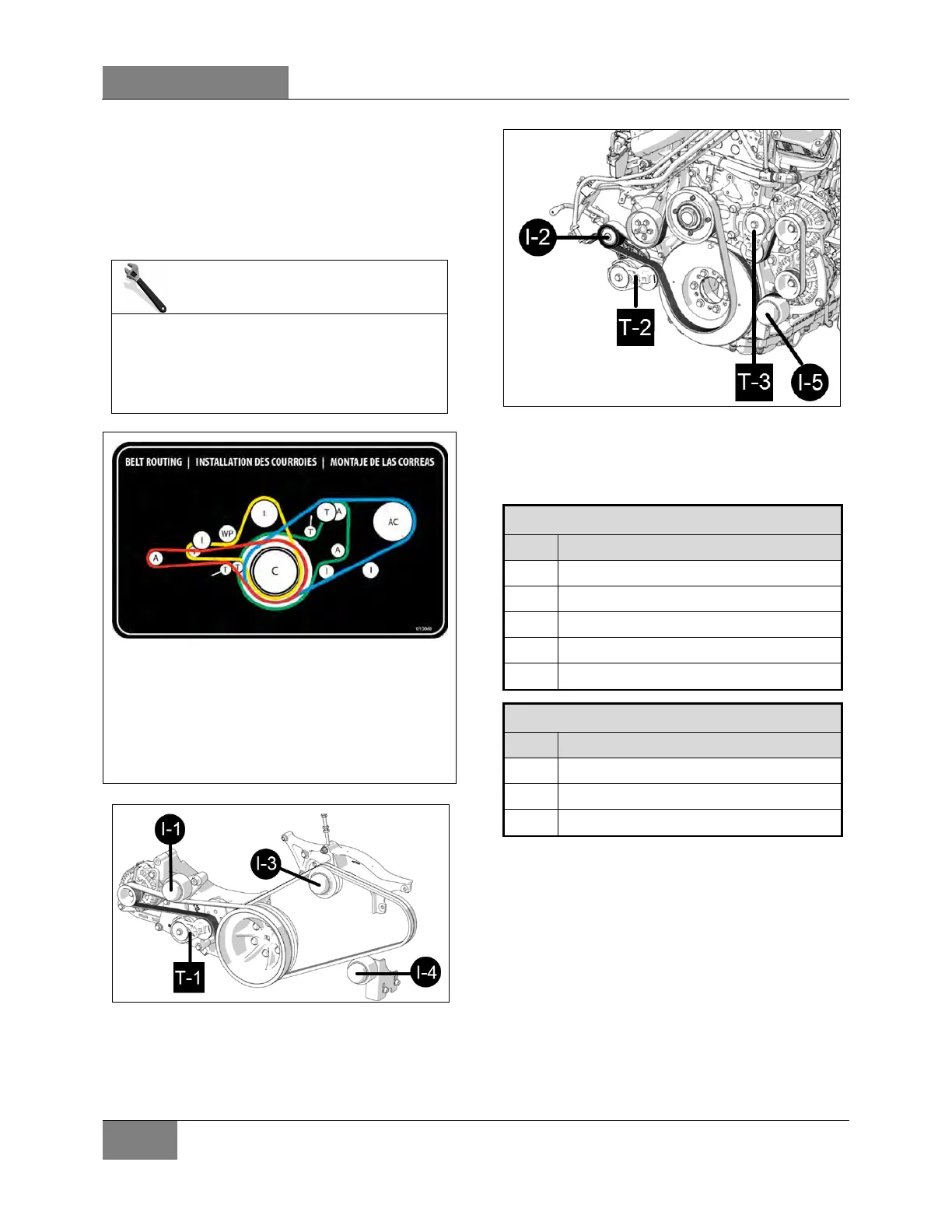

FIGURE 22: COACH BELT ROUTING

A=alternator

C=crank pulley

I=dler

WP=water pump

T=tensioner

AC=air conditioning compressor

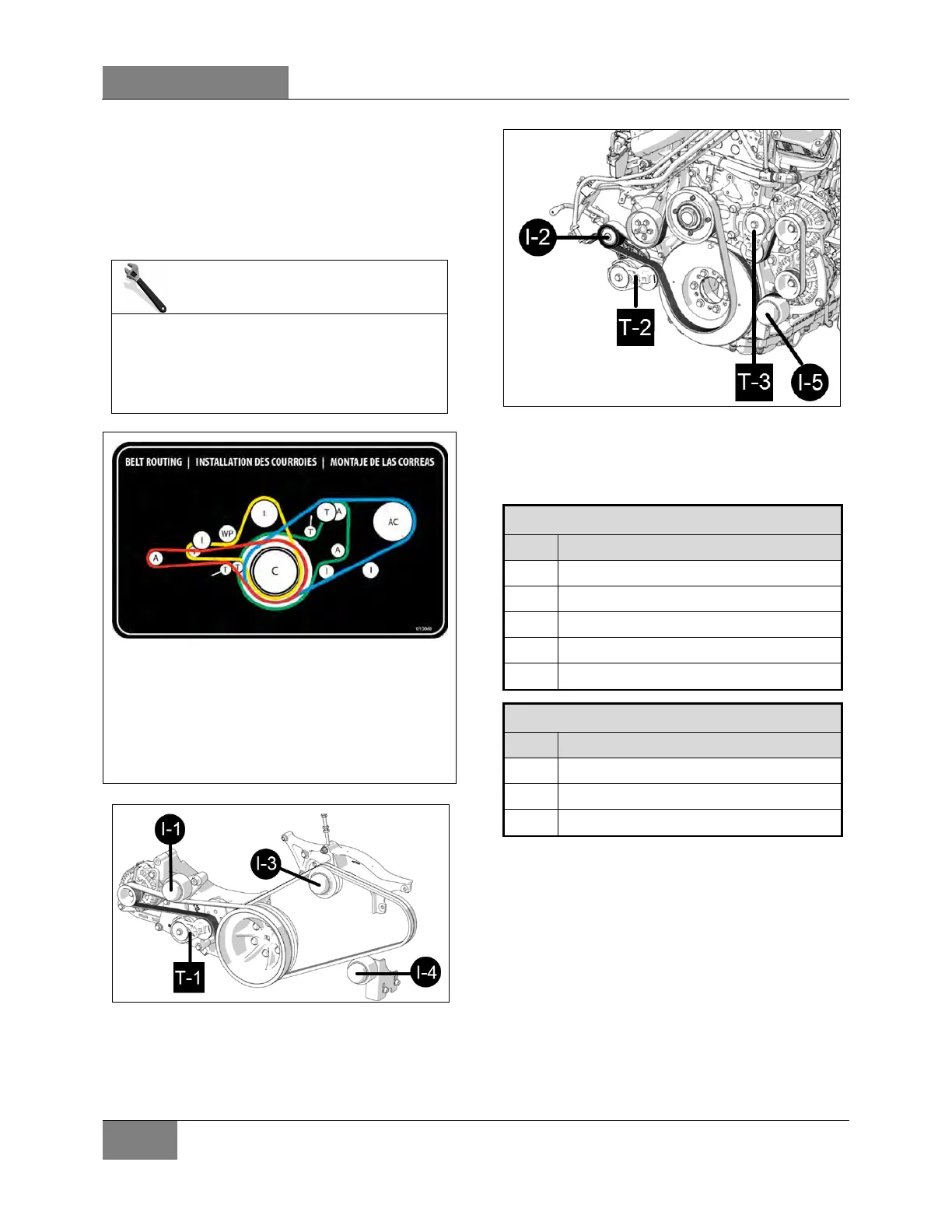

FIGURE 23: IDLER PULLEYS & AUTOMATIC BELT

TENSIONERS

I= IDLER

T= TENSIONER

FIGURE 24: IDLER PULLEYS & AUTOMATIC BELT

TENSIONERS

I= IDLER

T= TENSIONER

IDLERS

REF SYSTEM

I-1 L.H. SIDE ALTERNATOR

I-2 WATER PUMP DRIVE

I-3 A/C COMPRESSOR DRIVE

I-4 A/C COMPRESSOR DRIVE

I-5 R.H. SIDE ALTERNATOR DRIVE

AUTOMATIC BELT TENSIONERS

REF SYSTEM

T-1 L.H. SIDE ALTERNATOR

T-2 WATER PUMP DRIVE

T-3 R.H. SIDE ALTERNATOR DRIVE

4.1 BEARING INSPECTION

1. First, set parking brake, turn the ignition

OFF and set the rear start selector switch to

the OFF position.

2. Remove all belts on left hand alternator,

water pump drive, A/C compressor drive and

alternator drive.

3. Spin all idler pulleys, I-1 thru I-5, plus the

idlers that are part of the automatic belt

tensioners T-1 thru T-3.

4. Listen if some idlers are noisy and check for

play in the bearings by hand.

Loading...

Loading...