DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

Using the fluid level dipstick filler tube, refill with

28 US qts (26.5 liters) and check the fluid level

using the Fluid Level Check Using

Pushbutton Shift Selector procedure in this

section. Add transmission fluid according to

pushbutton shit selector fluid level check.

3.6 CLEANING AND INSPECTION OF

ALLISON AUTOMATIC TRANSMISSION

The exterior of the transmission should be

cleaned and inspected at regular intervals. The

length of service and severity of operating

conditions will determine the frequency of such

inspections. Inspect the transmission for:

1. Loosen bolts (transmission and mounting

components);

2. Fluid leaks (correct immediately);

3. Loose, dirty, or improperly adjusted throttle

sensor linkage;

4. Damaged or loose fluid lines;

5. Worn or frayed electrical harnesses, improper

routing;

6. Worn or out of phase drive line U-joint and slip

fittings.

CAUTION

DO NOT pressure wash the transmission

electrical connectors. Water and detergent will

cause the contacts to corrode or become faulty.

3.6.1 Breather

The breather is located on the engine, flywheel

side near the valve cover. It serves to prevent

pressure build-up within the transmission and

must be cleaned to keep the passage opened.

The prevalence of dust and dirt will determine the

frequency at which the breather requires cleaning.

Use care when cleaning the engine. Spraying

steam, water or cleaning solution directly at the

breather can force the water or solution into the

transmission. Always use care when removing the

hose connector from transmission to prevent the

entry of foreign matter.

4. ALLISON TRANSMISSION FLUID

COOLER REMOVAL

4.1 TRANSMISSION WITH RETARDER

Stop engine and allow engine to cool. Close both

heater line shutoff valves (refer to Section 05

‘’Cooling’’).

1. To drain the cooling system, proceed as per

Section 05 ‘’Cooling’’, paragraph 5: Draining.

If the cooling system is contaminated, flush

system as per Section 05 ‘’Cooling’’,

paragraph 7: Flushing.

2. Remove the rear L.H. side tag axle wheel,

then remove the rear L.H. side fender panel.

3. Disconnect the transmission hoses from fluid

cooler. Cover hose ends and fittings to

prevent fluid contamination.

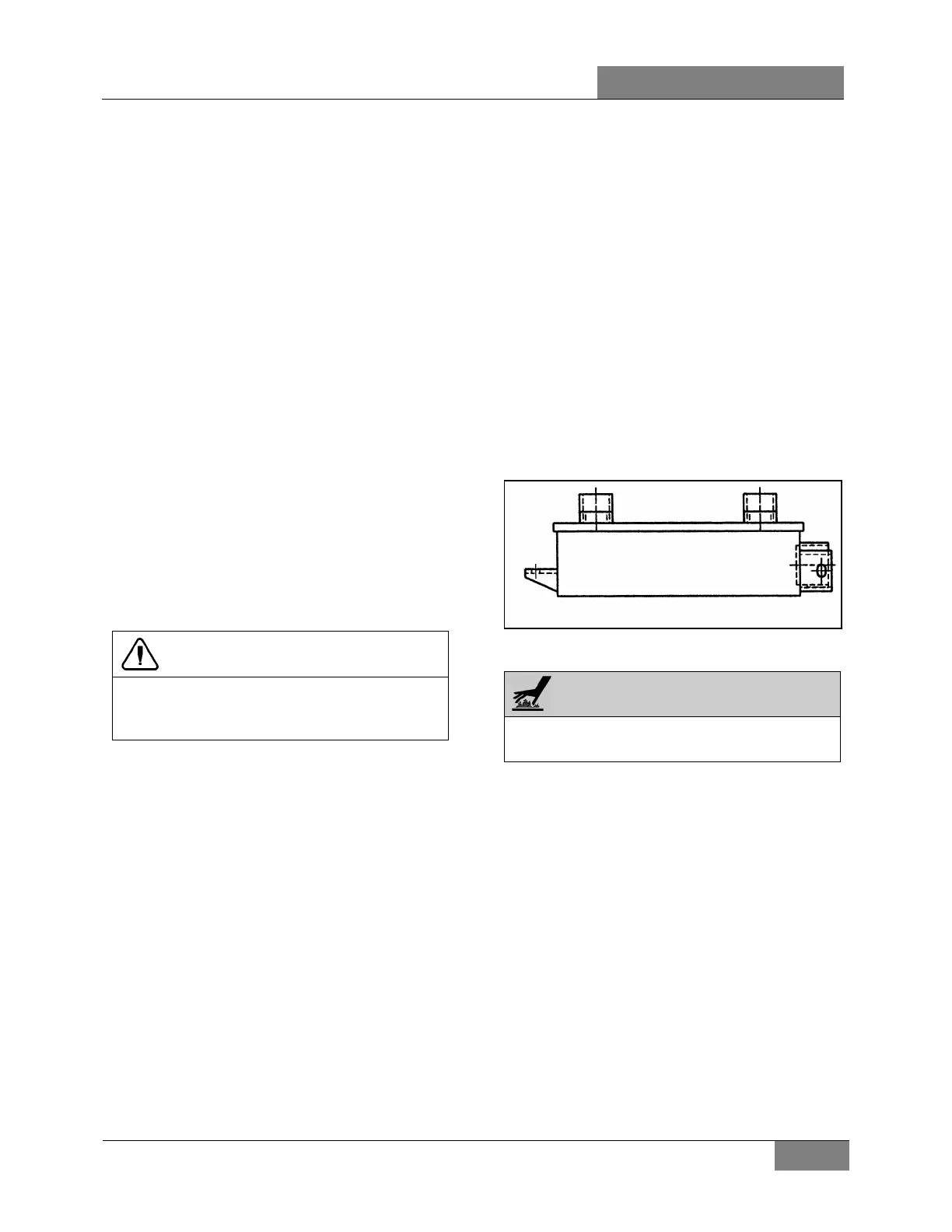

FIGURE 7: COOLER WITH RETARDER (07073)

WARNING

A significant amount of fluid

fluid lines when they are disconnected.

4. Unfasten the constant-torque hose clamps

and remove the two hoses.

5. Unscrew the holding bolts and nuts and

remove the fluid cooler from engine

compartment.

5. ALLISON TRANSMISSION REMOVAL

The following procedure deals with the removal of

the Allison transmission without removing the

power plant cradle from vehicle. The methods

used to support the transmission and engine

depend upon conditions and available equipment.

1. Select transmission's "NEUTRAL" positions,

apply parking brake, and then set battery

master switch to the "OFF" position.

2. Jack up vehicle, then place safety supports

underneath body.

Loading...

Loading...