SECTION 22: HEATING AND AIR CONDITIONING

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

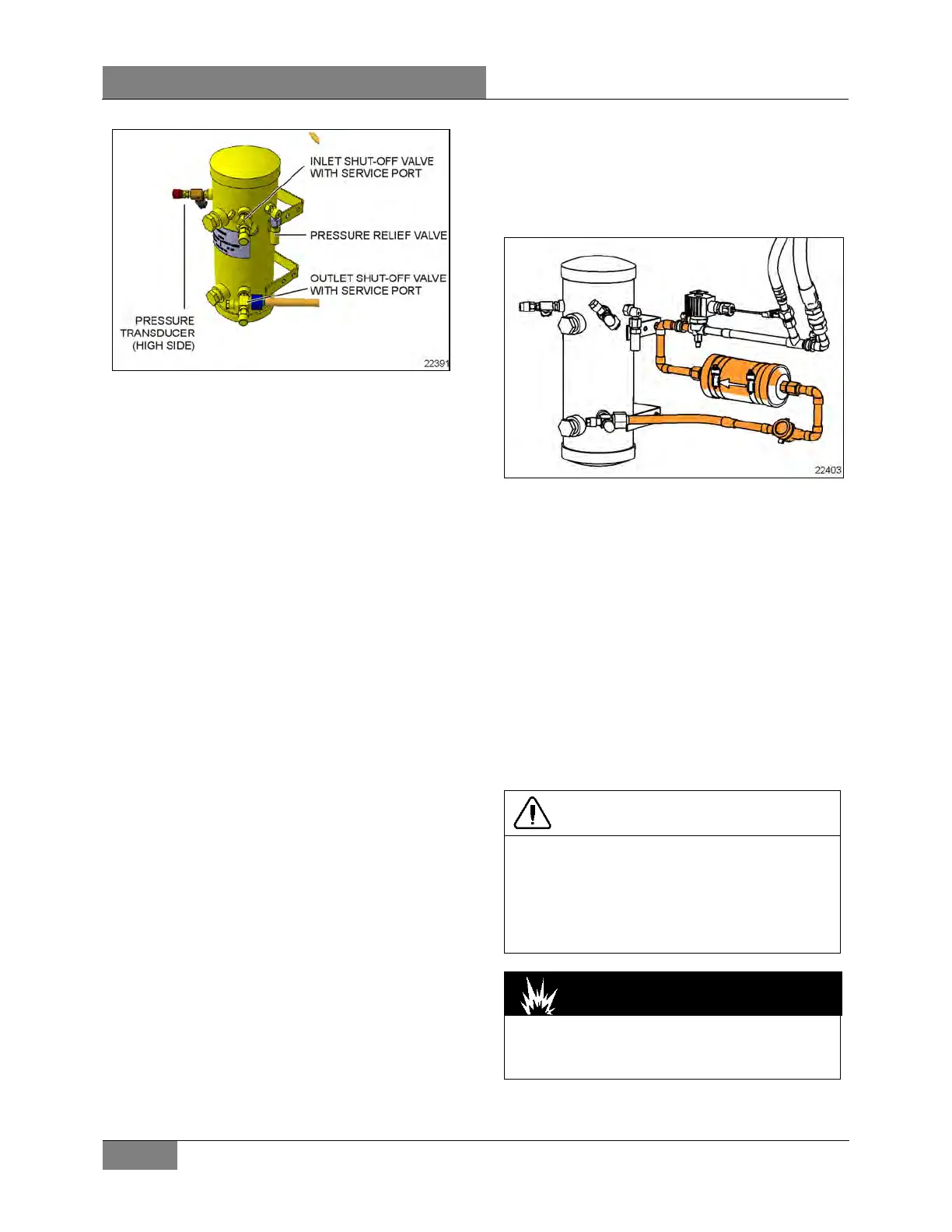

FIGURE 28 RECEIVER TANK X SERIES

In case of extreme pressure there will be a rise

in the liquid receiver tank. A pressure relief

valve will break at 450 psi and relieve the

receiver tank pressure.

The receiver tank incorporates an inlet valve on

the inlet side (upper section) which allows the

tank to be isolated or serviced. An outlet valve

on the outlet side (lower section) permits

complete isolation from the rest of the system.

During normal operation, inlet and outlet

shutoff valves are in back seated position (stem

out).

When connecting a gage to the service port,

make sure the shut-off valve is in back seated

position because the service port is not fitted

with a Schrader valve.

4.5 FILTER DRYER

A filter dryer, also located in the condenser

compartment, is installed on the liquid refrigerant

line after the receiver tank. It is used to absorb

moisture and foreign matter from refrigerant

before it reaches the expansion valves.

The filter dryer should be replaced after a

severe system failure, after a prolonged

exposure and most important, when the

moisture indicator sight glass turns to pink.

4.5.1 Replacement of the Filter-Dryer After

Pumping Down

The filter dryer is of the disposable type. When

replacement is required, remove and discard the

complete unit and replace with a new unit of the

same type according to this procedure:

1. Perform the pumping down procedure to

isolate refrigerant in the receiver tank.

2. Disconnect C24 to isolate the section of the

system located between the receiver tank

outlet shutoff valve and the passengers unit

liquid solenoid valve.

3. Change the filter dryer.

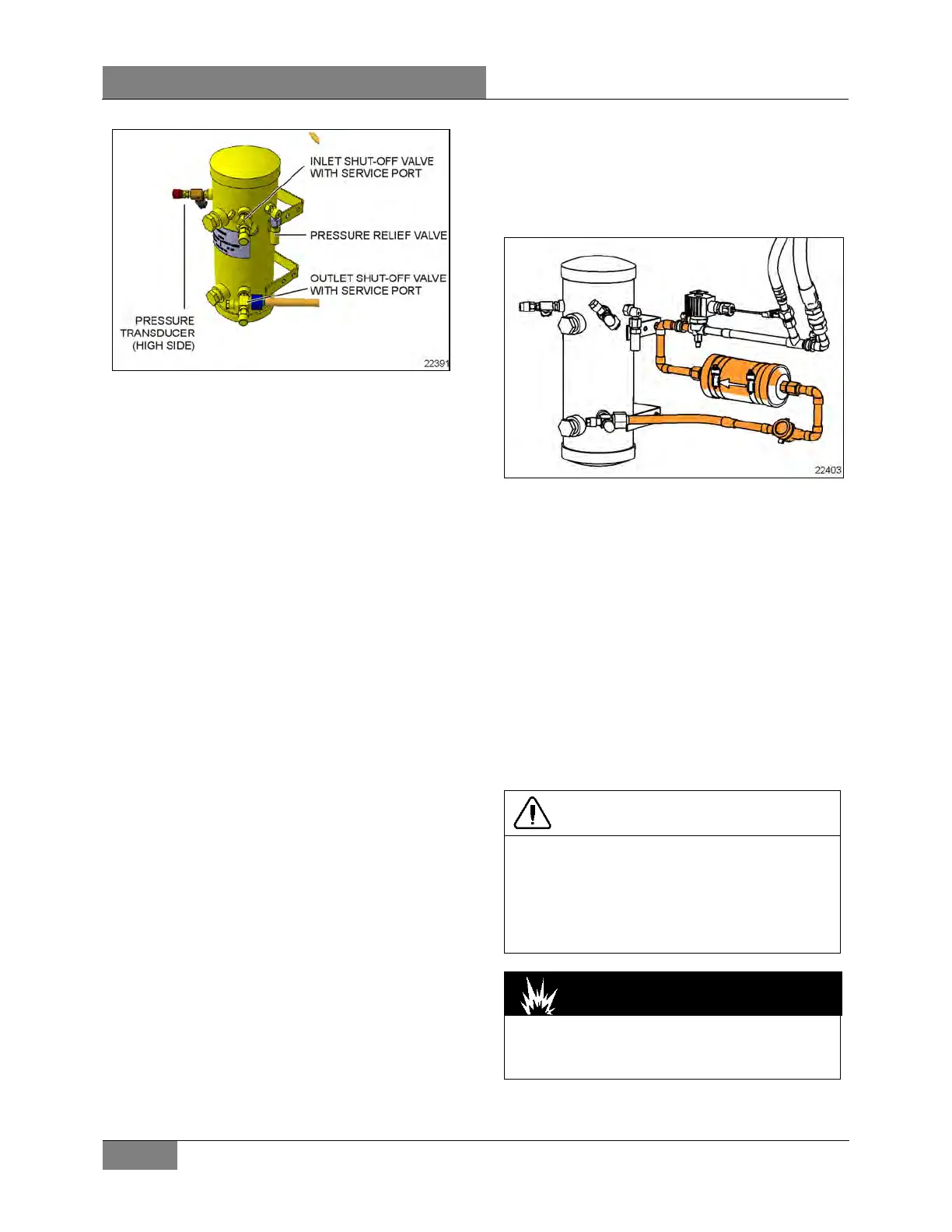

FIGURE 29: ISOLATED SECTION X SERIES

4. Once the filter dryer has been replaced, it is

necessary to evacuate the opened section

of the refrigerant circuit. Evacuate the

isolated section of the system using a

vacuum pump connected to the service port

of the receiver outlet shutoff valve.

5. Evacuate the section of the refrigerant

piping as needed and in accordance with

best practices, using a micron gage to

monitor the depth of vacuum. Evacuate to a

system pressure less than 1000 microns.

6. Turn off the vacuum pump.

7. Backseat the outlet shutoff valve and then

disconnect the vacuum pump hose.

CAUTION

Do not use carbon tetrachloride or similar

solvents to clean parts. Do not

guns

. Use mineral spirits or naphtha. All

parts should be thoroughly cleaned. Use a

stiff brush to wash dirt from grooves, holes,

etc.

DANGER

Cleaning products are flammable and may

explode under certain conditions. Always

handle in a well-ventilated area.

Loading...

Loading...