SECTION 22: HEATING AND AIR CONDITIONING

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

4.6 MOISTURE INDICATOR

The moisture sensitive element consists of a

color-changing ring which is reversible from pink

to blue and vice versa as the moisture content in

the refrigerant changes.

•

moisture detected.

• PURPLE (caution)

levels of moisture detected.

•

operating conditions.

Since temperature changes affect the solubility,

color change will also vary with the refrigerant

temperature. The above table shows the color

change for R-134a at various moisture levels

and liquid line refrigerant temperatures.

MAINTENANCE

Check refrigerant moisture indicator

intervals specified by the

Servicing Schedule in Section 24A.

Replace filter-dryer unit according to moisture

indicator.

COLOR INDICATOR

TEMPERATURE

BLUE

(ppm)

LIGHT

VIOLET

(ppm)

PINK

(ppm)

75°F (24°C)

100°F (38°C)

125°F (52°C)

20

35

60

35

55

65

130

160

190

p.p.m.= parts per million (moisture content)

A moisture level of less than 15 p.p.m. for R-

134a indicated in the blue color range of the

above table is generally considered dry and

safe. A color indication of light blue to light violet

indicates the caution range of moisture level. For

positive protection, the drying of the system

should be continued until the color of the

element turns to deep blue.

The liquid refrigerant is readily visible through

the center opening of the moisture element

where the presence of bubbles or flash gas

indicates an insufficient system charge, low

head pressure, insufficient liquid sub cooling or

some form of restriction in the liquid line.

Moisture is one of the main causes of chemical

instability or contamination in air-conditioning

systems. If moisture is present, it can corrode

the valves, condenser and evaporator coils,

compressor and other components causing a

malfunction and eventual failure of the system.

Uncontrolled moisture in the system can result in

very expensive multiple component

replacements if not corrected at an early stage.

The moisture indicator permits an early

detection of moisture in the system and when

corrected by a desiccant charge, system

contamination is greatly minimized.

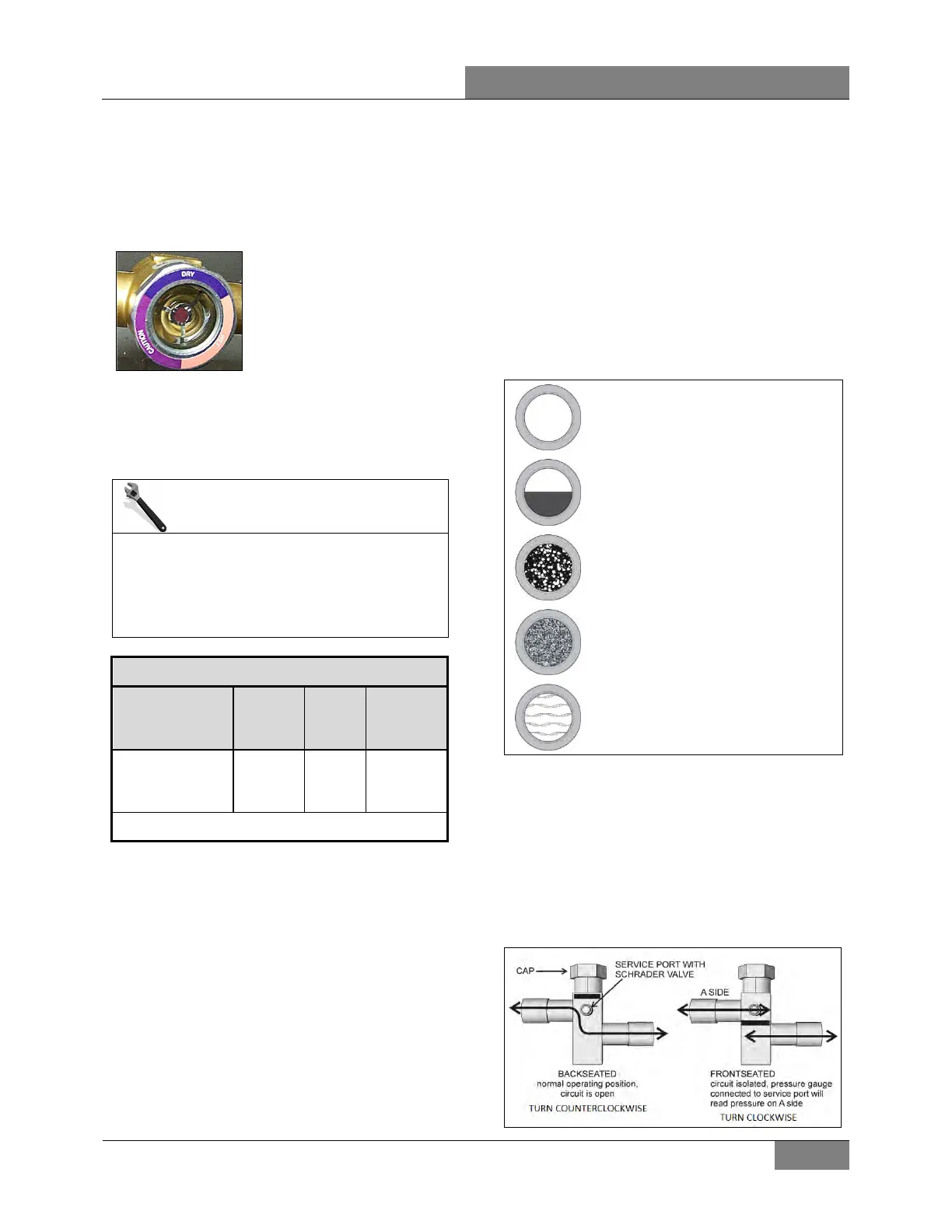

CLEAR

Normal, system OK

Temporary condition, normal when A/C

system is turned on. Wait a few minutes

for the system to stabilize.

BUBBLES, FOAMY

Low refrigerant level

Excessive pressure drop in filter dryer

MILKY, CLOUDED

Contaminated system

OIL STREAKS

Oil contamination

FIGURE 30: CONDITIONS THAT MAY BE OBSERVED IN

THE MOISTURE INDICATOR SIGHT GLASS

4.7 SHUTOFF VALVE WITH SERVICE

PORT

This shutoff valve (FIGURE 31) is located in the

condenser compartment. It is used to isolate one

section of the refrigerant circuit. The service port

is equipped with a Schrader valve.

Loading...

Loading...