DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

97

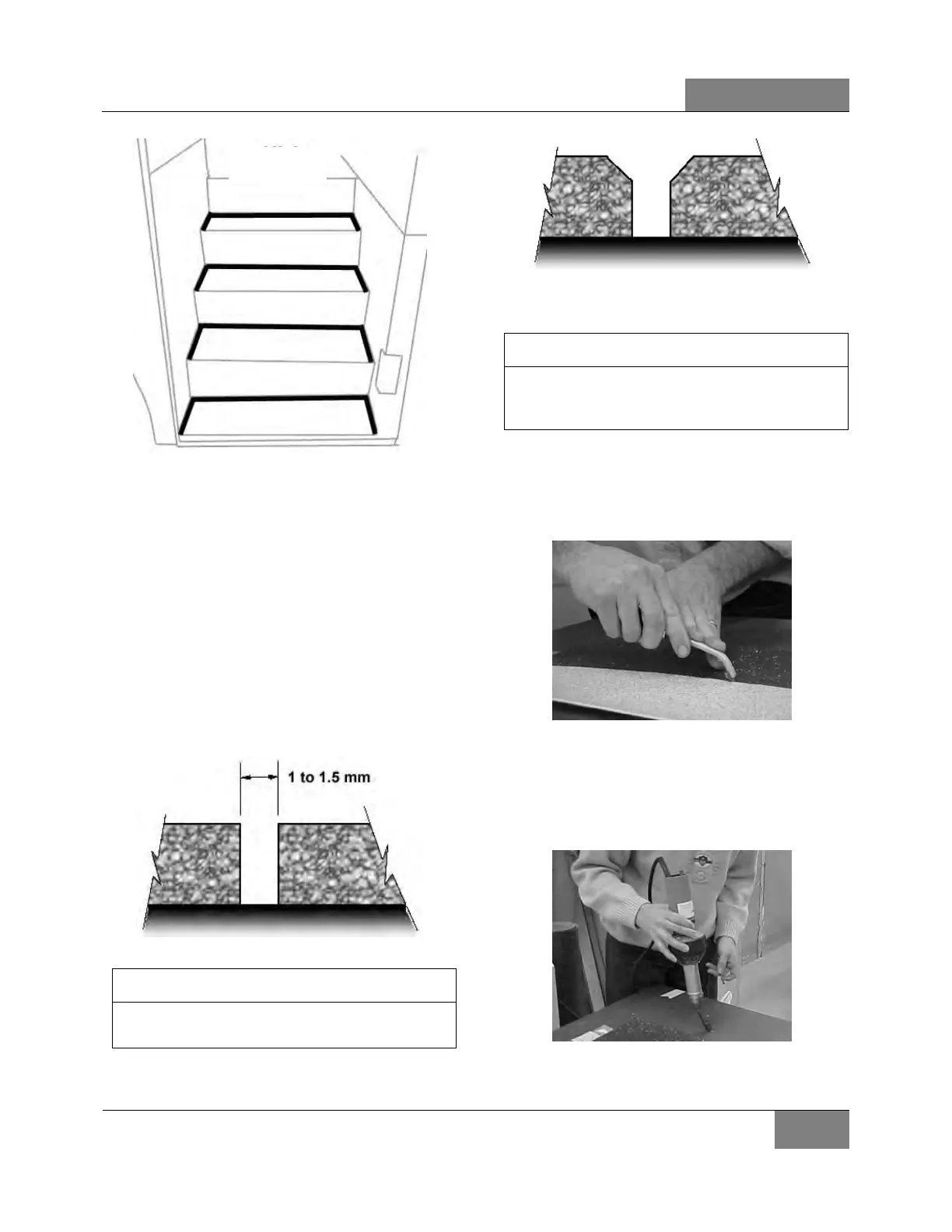

12.3.2 Welding Of Joint Between White

Safety Strip And “Tarabus” Floor

Covering

1. Pre-heat welding torch;

o Set welding torch to position #4.5

(temperature of 500 °C),

o Heating time: 5 minutes.

2. Before welding, visually ensure that a 1 to

1.5 mm gap exists between white safety strip

and “Tarabus” floor covering. Use a knife if

this is not the case.

There should be no excess of adhesive on top

of surfaces, clean if required using “All-Sol”.

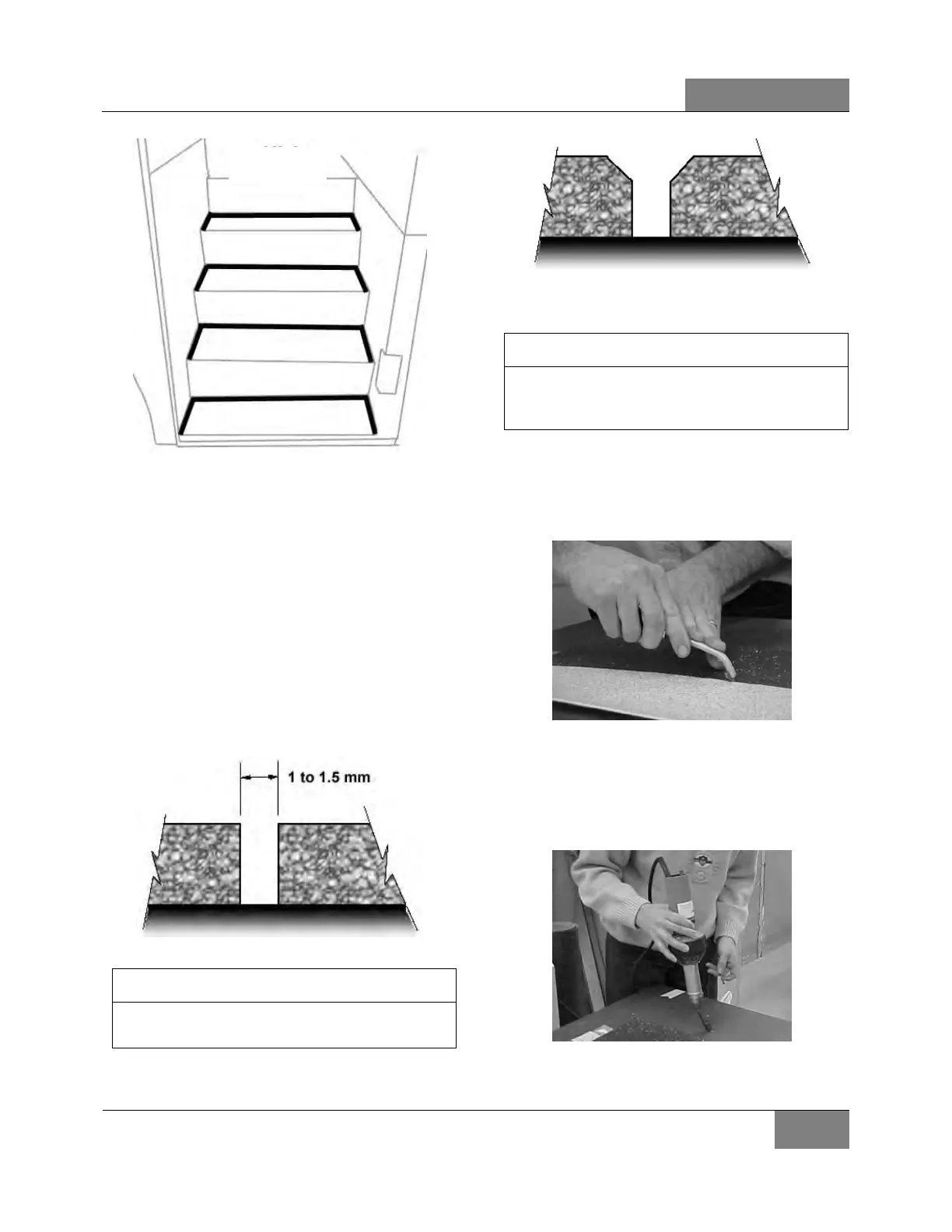

3. Chamfer the joint.

The chamfer width must always be less than

the filler bead diameter (between 2.5 and 3

mm).

4. Use chamfer knife. Be careful not to

overcut or to cut to the side to prevent

damaging “Tarabus” covering.

5. Add (about 6 inches) some length to the

required length of filler bead to make the

joint then cut.

6. Take position with welding torch. The proper

position is with a slight slope to the rear.

7. Once the welding torch is ready, insert the

filler bead into the nozzle and immediately

Loading...

Loading...