DOB 1300-1556| X3-45 Commuter PA-1648 Maintenance Manual Section 23 revised Nov 2021

8. SNOW CHAIN SYSTEM

The vehicle is equipped with a driver activated

snow chain system that will deploy under the

drive wheels to provide added traction on ice

and snow.

To ensure optimal performance, a regular

inspection of the system components must be

performed and wearable parts replaced as

required.

8.1 PREVENTIVE INSPECTION AND

MAINTENANCE

MAINTENANCE

Snow Chain System

Inspect and replace components at intervals

specified by the Lubri

cation And Servicing

Schedule in Section 24: LUBRICATION &

SERVICING.

Do not exceed recommended service intervals.

1. Inspect all parts for damage or excessive

rust.

2. Check all fasteners for correct torque (refer

to the torque table at the beginning of this

section).

3. Check air lines, valves and solenoids for leak

when the system is engaged.

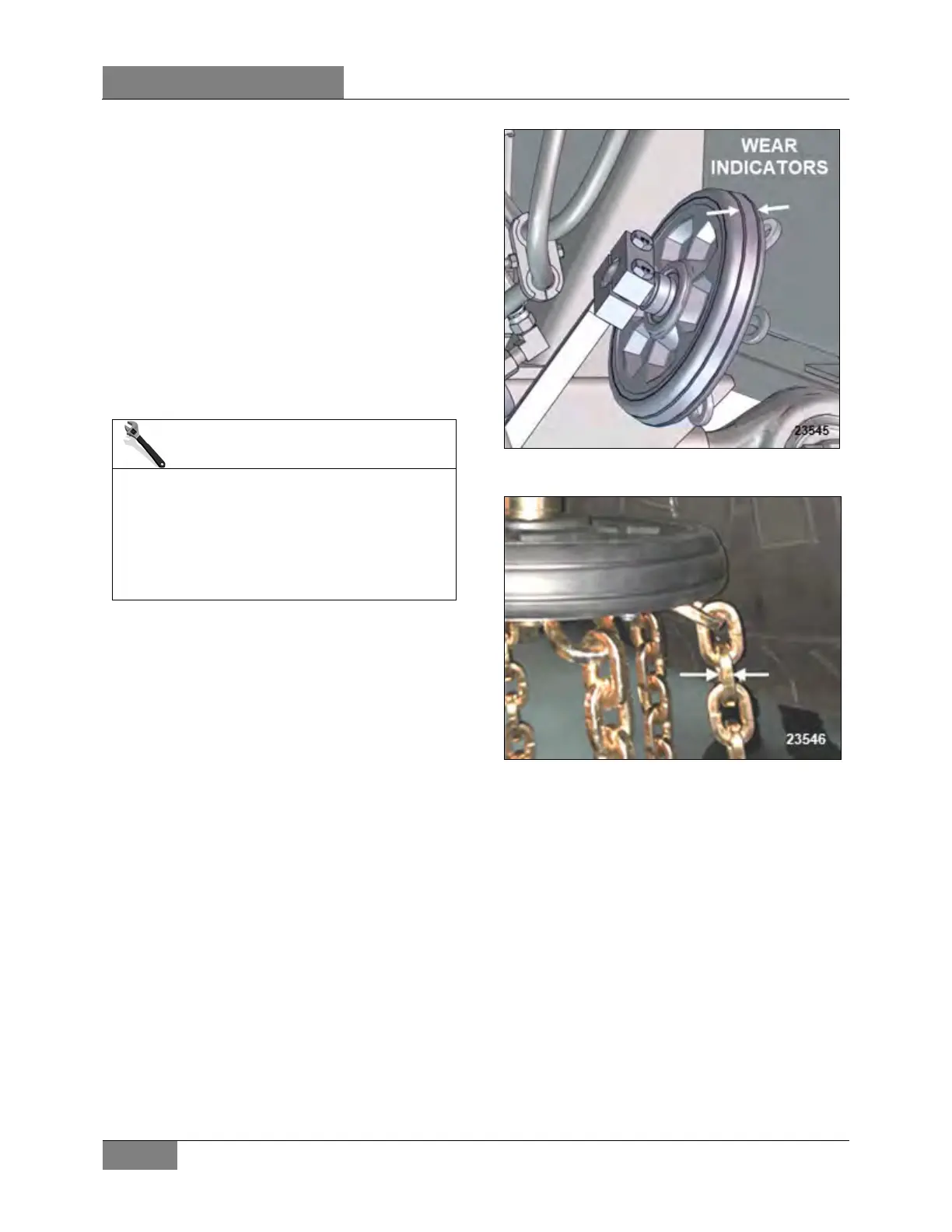

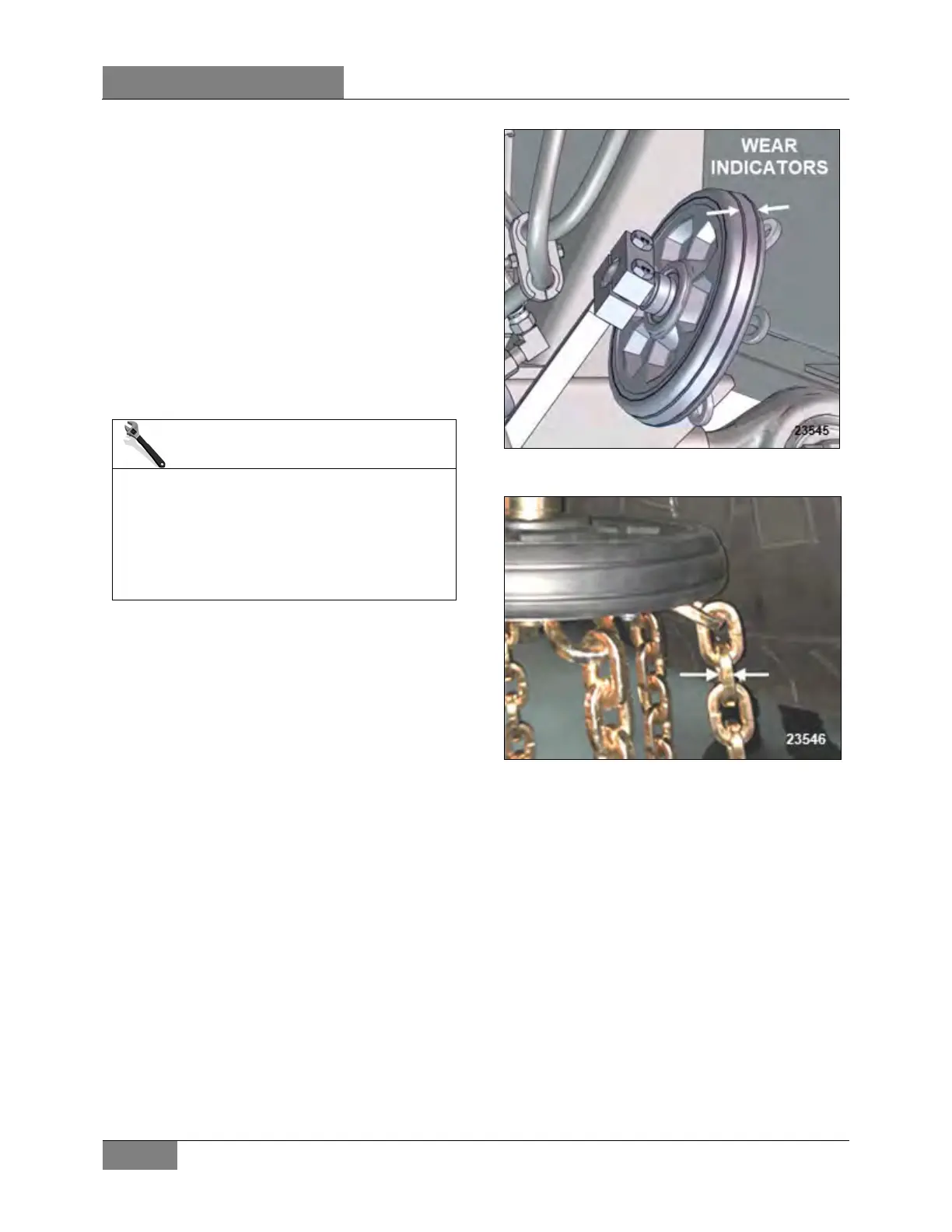

4. Inspect contact ring rubber and chain strands

for wear.

• Replace wheel assembly when rubber

ring indicators are fading out or if the

wheel bearing is not spinning freely

(FIGURE 30).

• Replace wheel assembly when any of

the chain strands reach 0.130in

(3.25mm) in diameter (equivalent to

50% wear FIGURE 31)

5. Inspect inside sidewall of the tires. Tire wear

indicates misalignment or damage to the

system.

FIGURE 30: WEAR INDICATORS ON RUBBER CONTACT

RING

FIGURE 31: CHAIN STRAND MIN DIAMETER 0.130”

6. Check for proper chain wheel angle and

position in relation to the vertical centerline of

the tire (see 8.2 POSITIONING

REQUIREMENTS).

7. To keep the system in good working order,

carry out the swiveling action once a week.

This can be done with the vehicle in a

stationary position by one of these ways:

• Pressing on the button located on top of

the system valve in the front pneumatic

compartment (this will bypass the

electrical activation system as shown in

FIGURE 32).

Loading...

Loading...