DOB 1300-1556| X3-45 Commuter PA-1648 Maintenance Manual Section 23 revised Nov 2021

2. HUB ODOMETER

A wheel hub odometer (Figure 1) have been

installed on the R.H. side of the drive axle. It

indicates the total distance in miles covered by

the coach since it has left the factory, including

road testing.

FIGURE 1: HUB ODOMETER 23024

2.1 OPERATION

The hub odometer is calibrated for a specific

wheel size (diameter). Wheel rotation causes a

mechanism inside the hub odometer to record

distance after a predetermined number of

rotations. The unit should be serviced at a

competent speedometer repair facility.

Do not use paint, solvent or thinner on hub

odometer face or on plastic hubcaps. Do not

weld on hub odometer.

2.2 REMOVAL

To remove the unit, remove the two lock nuts

and washers securing it to the wheel hub, and

pull the unit off the studs.

2.3 INSTALLATION

Place the hub odometer unit over the wheel hub

studs. Replace the lock washers and nuts.

Torque stud nuts.

TORQUE: 110-165 lb-ft (149-224 Nm)

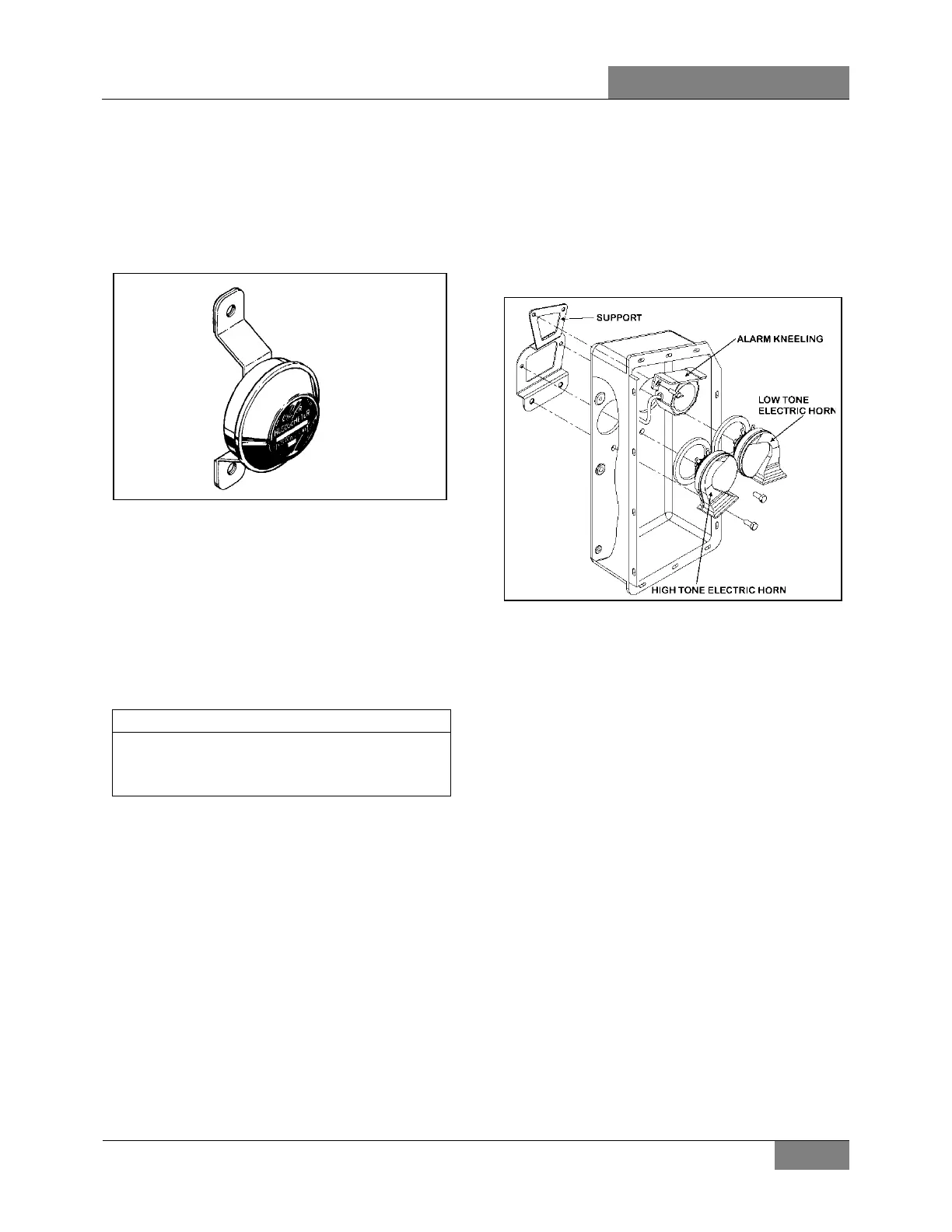

3. HORN INSTALLATION

The electric and air horns are located in a plastic

box under the front step well and are accessible

from the front body substructure. Refer to

Operator’s or Owner’s Manual for operation.

FIGURE 2: ELECTRIC & AIR HORN INSTALLATION 23420

3.1 ELECTRIC HORN MAINTENANCE

When needed, the electric or air horn can be

serviced or replaced using the following

procedure:

1. Raise vehicle by the jacking points;

2. Unplug the cable connector;

3. Disconnect the air tube if applicable;

4. Loosen the retaining bolts;

5. Service or replace the defective horn;

6. Reinstall by reversing procedure.

Loading...

Loading...