DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

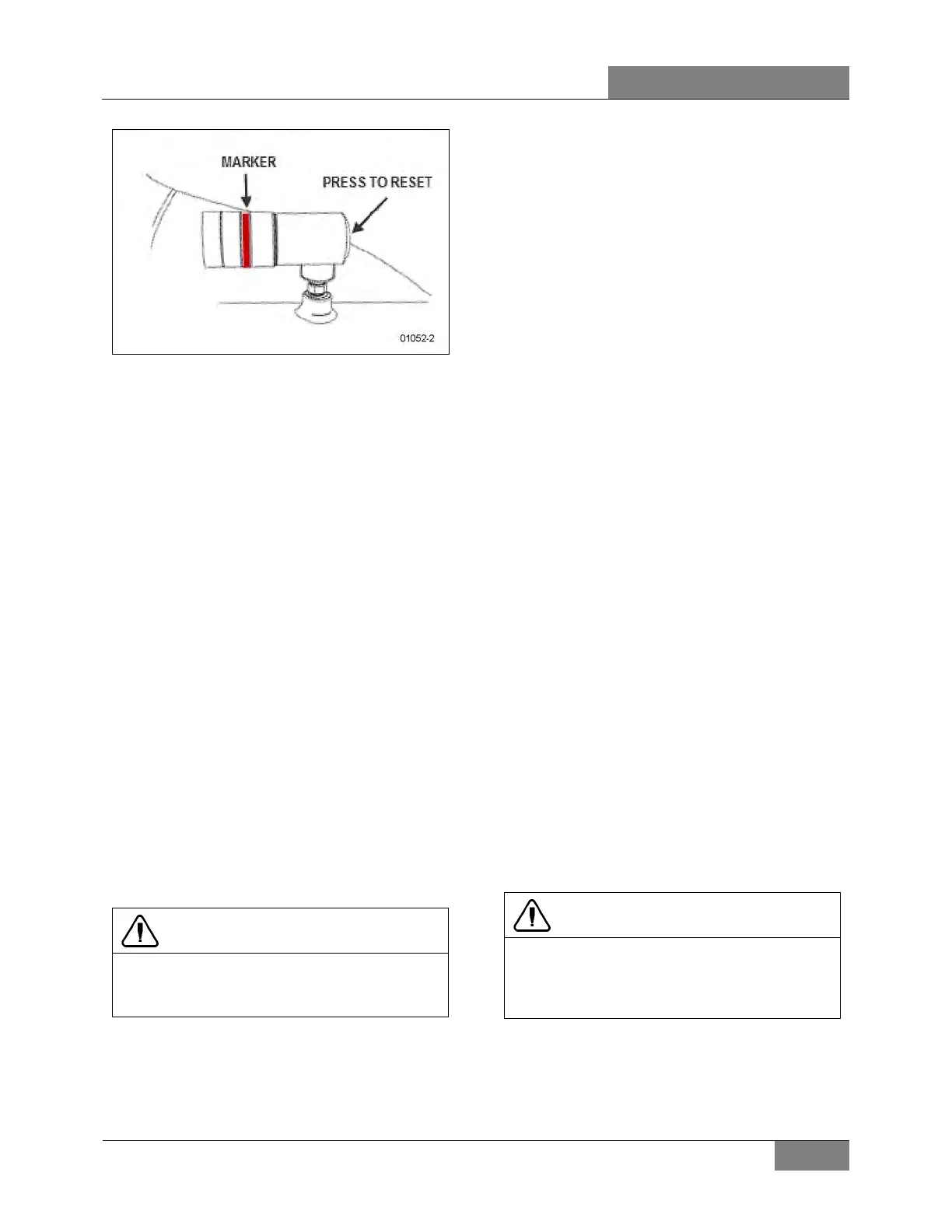

FIGURE 27: RESTRICTION INDICATOR

5.2 GENERAL RECOMMENDATIONS

The following maintenance procedures will

ensure efficient air cleaner operation:

1. Keep the air cleaner housing tight on the air

intake pipe;

2. Make sure the correct filters are used for

replacement;

3. Keep the air cleaner properly assembled so

the joints are air-tight;

4. Immediately repair any damage to the air

cleaner or related parts;

5. Inspect, clean or replace the air cleaner or

elements as operating conditions warrant.

Whenever an element has been removed

from the air cleaner housing the inside

surface of the housing must be cleaned with

a soft clean cloth;

6. Periodically inspect the entire system.

Dust-laden air can pass through an almost

invisible crack or opening which may

eventually cause damage to an engine;

7. Never operate the engine without an element

in the air cleaner assembly;

CAUTION

Do not ignore the Warning given by the air

restriction indicator. This could result in

serious engine damage.

8. Store new elements in a closed area free

from dust and possible damage.

6. ACCELERATOR PEDAL

The EFPA (Electronic Foot Pedal Assembly)

connects the accelerator pedal to a

potentiometer (a device that sends an electrical

signal to the ECM, which varies in voltage,

depending on how far down the pedal is

depressed). The EFPA is installed in the space

normally occupied by a mechanical foot pedal. It

has maximum and minimum stops that are built

into the unit during manufacturing.

6.1 PEDAL ADJUSTMENT

The EFPA contains a throttle position sensor

that varies the electrical signal sent to the ECM.

The sensor must be adjusted whenever an

EFPA is serviced. In addition, the sensor should

be adjusted any time codes 21 and 22 are

flashed.

With the ignition "ON" and the proper diagnostic

tool (DDR) (for information regarding the DDR,

see "01 ENGINE" in this manual), check the

throttle counts at idle and full throttle positions.

Proper pedal output should be 20/30 counts at

idle and 200/235 at full throttle. If adjustment is

necessary, remove the potentiometer retaining

screws and rotate the potentiometer clockwise to

increase counts or counterclockwise to

decrease. When correct output is confirmed,

tighten retaining screws.

6.2 POTENTIOMETER REPLACEMENT

1. Disconnect cable harness connector.

2. Loosen the two screws and remove

potentiometer. Retain for re-assembly.

3. Discard potentiometer (Figure 28).

CAUTION

Note the routing and clamping locations of the

cable before disassembly. Proper cable

routing and fastening is critical to the

operation of this system.

4. Position new potentiometer. Press

potentiometer onto the potentiometer shaft,

matching cutouts in shaft to drive tangs of

potentiometer. Apply hand pressure until

Loading...

Loading...