SECTION 22: HEATING AND AIR CONDITIONING

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

pin to full open position, is of vital importance

because it provides savings in both initial

evaporator cost of operation.

Accurate and sensitive control of the refrigerant

liquid flowing to the evaporator is necessary to

provide maximum evaporator capacity under

load conditions. The spring is adjusted to give

12 to 16

o

F (-11.1 to -8.8

o

C) of superheat at the

evaporator outlet.

This ensures that the refrigerant leaving the

evaporator is in a completely gaseous state

when drawn into the suction side of the

compressor. Liquid would damage the

compressor valve, piston and heads if allowed to

return in the suction line.

A vapor is said to be superheated when its

temperature is higher than the saturation

temperature corresponding to its pressure. The

amount of the superheat is, of course, the

temperature increase above the saturation

temperature at the existing pressure.

As the refrigerant moves along in the

evaporator, the liquid boils off into a vapor and

the amount of liquid decreases until all the liquid

has evaporated due to the absorption of a

quantity of heat from the surrounding

atmosphere equal to the latent heat of

vaporization of the refrigerant. The gas

continues along in the evaporator and remains

at the same pressure. However, its temperature

increases due to the continued absorption of

heat from the surrounding atmosphere. The

degree to which the gas refrigerant is

superheated is related to the amount of

refrigerant being fed to the evaporator and the

load to which the evaporator is exposed.

4.9.2 Superheat Adjustment

Expansion valves are factory preset for optimum

superheat settings. This setting should be

modified only if absolutely necessary. The

readjustment should be at the lowest expected

evaporating temperature.

1. Operate coach for at least one-half hour at

fast idle with temperature control set at 82

o

F

(27,7

o

C), then set temperature to minimum

to keep the compressor on 4 cylinders.

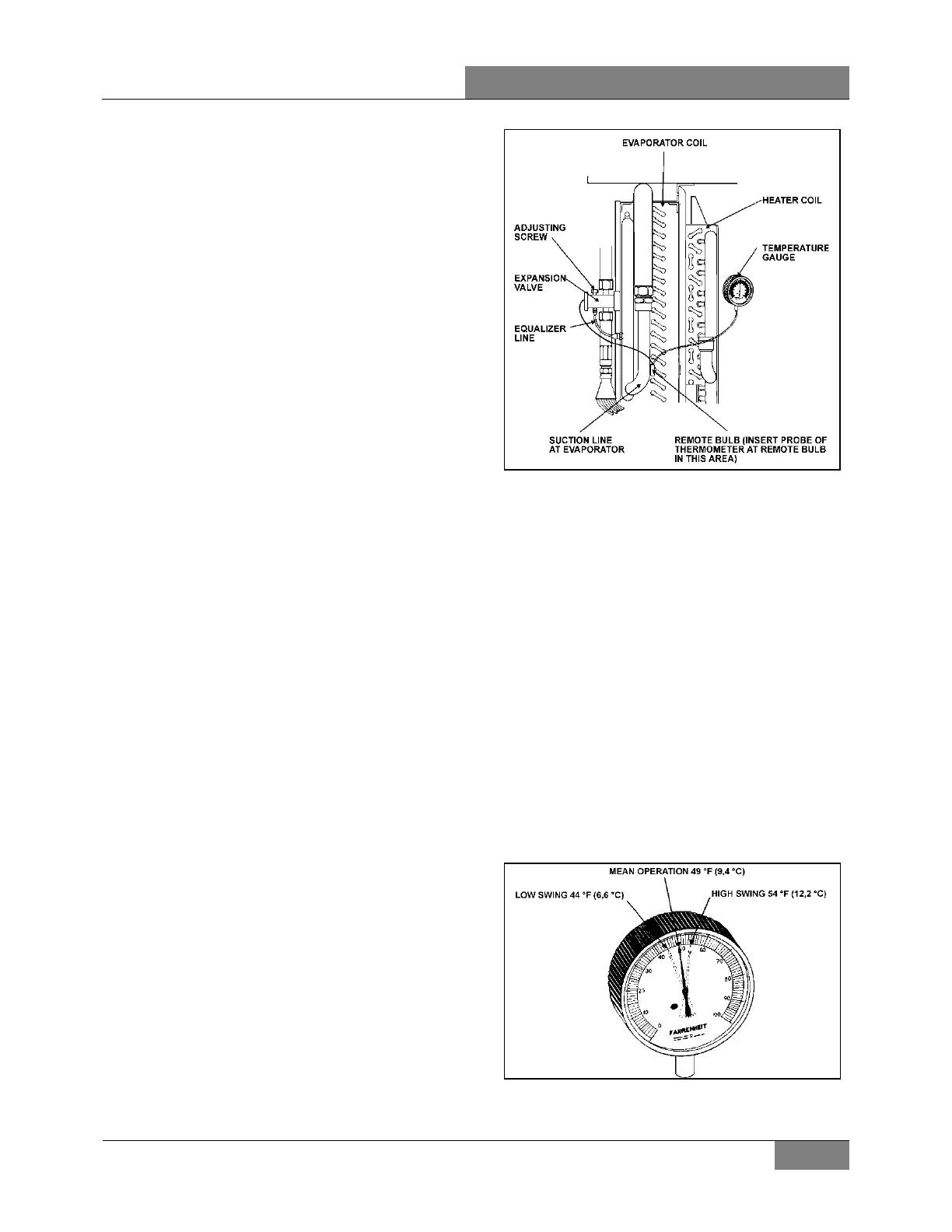

FIGURE 37: SUPERHEAT ADJUST. INSTALLATION 22046

2. In the DID “Gages” Menu note the indicated

“LoS” (Low side) pressure.

3. Use a remote reading thermometer or

thermocouple / multimeter to measure

temperature at the evaporator outlet line

near the existing remote bulb (Figure 37).

4. Apply thermostatic tape around the bulb

and evaporator outlet line to get a true

reading of the line temperature.

5. Block condenser if necessary to keep

pressure over 150 psi.

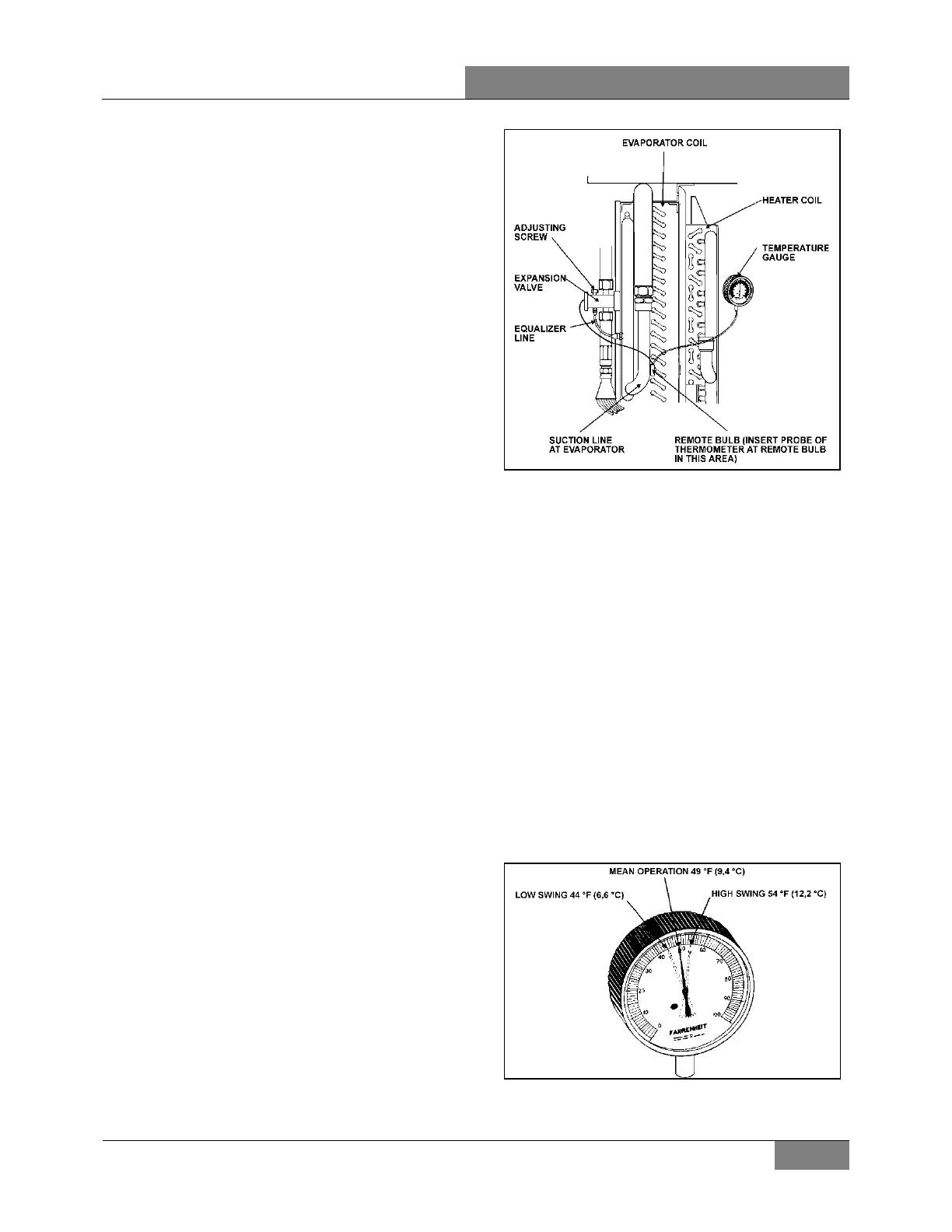

6. Check approximately 5 readings of pressure

at 2-minute intervals and convert to

temperature using the vapor-pressure table.

Likewise check the temperature reading at

the remote bulb at the same 2-minute

intervals and record the low and high swing

readings of the needle (Figure 38).

FIGURE 38: HIGH & LOW SWING TEMPERATURE AT

REMOTE BULB

22047

Loading...

Loading...