DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

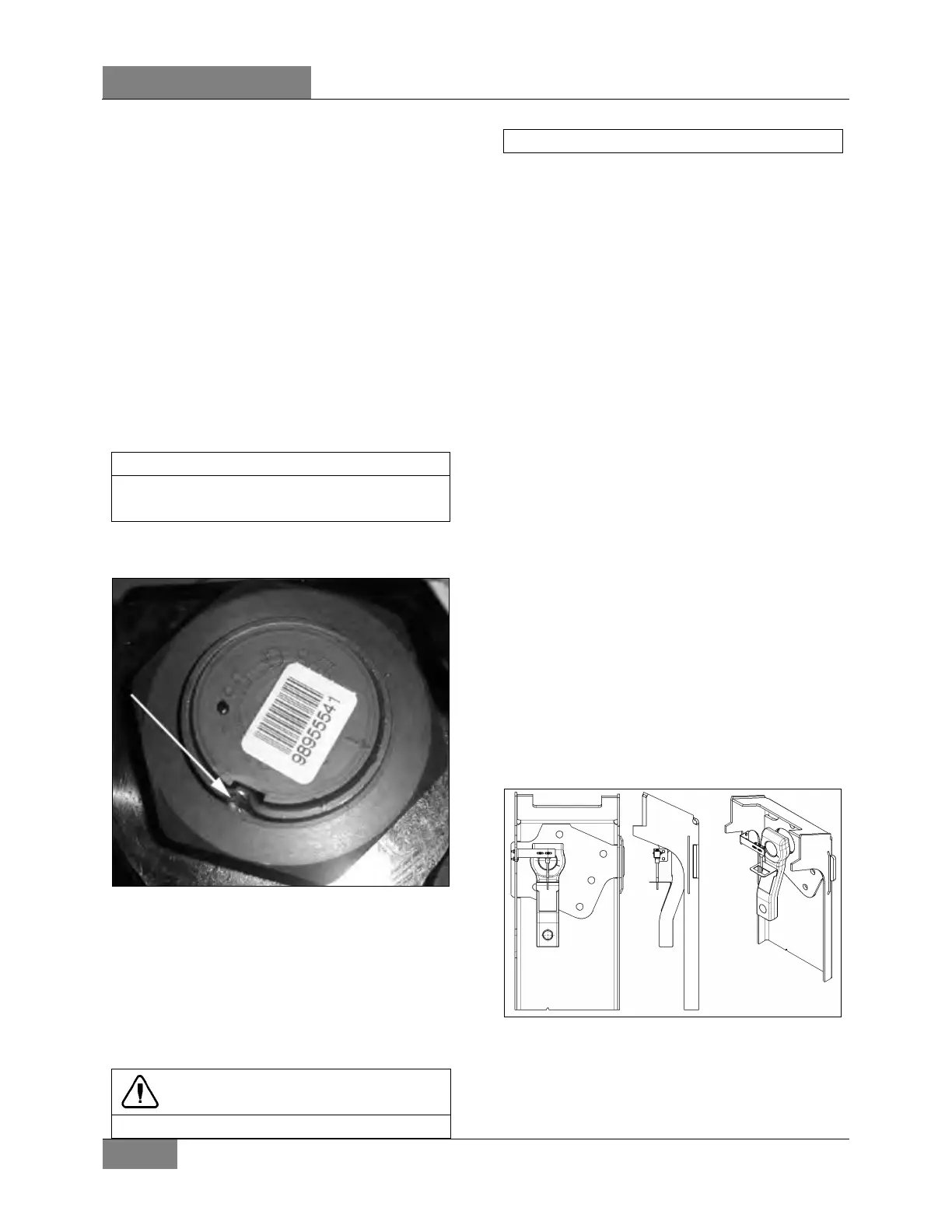

FIGURE 16: I-BEAM FRONT AXLE PIT MAN ARM

ADJUSTMENT

6. Add reference marks to the arm and shaft if

necessary to ensure correct alignment at

reassembly.

7. Use a suitable puller and remove pitman

arm.

11.2 INSTALLATION

1. Position pitman arm on sector gear shaft

with reference marks aligned.

2. Install fixing nut.

TORQUE: 470-570 lb-ft (637-773 Nm)

Use a new nut if the previously removed nut

was punched.

1. Lock nut with sector shaft using a punch

mark into the groove (Refer to Figure 17).

FIGURE 17: FIXING NUT PUNCH MARK 16098

2. Connect drag link to pitman arm while

ensuring that rubber stabilizer is in

place on the rod end. Install washers.

Tighten nut and install a new cotter pin.

Depending on axle type, select the

appropriate torque,

TORQUE: 165-236 lb-ft (224-320 Nm)

CAUTION

Input shaft marks must be aligned before

11.3 ADJUSTMENT

1. Disconnect the drag link from pitman arm.

Center steering wheel by dividing the total

number of steering wheel turns in two.

Scribe a reference mark on steering gearbox

at the center previously determined.

2. Using a protractor, check the angle of the

pitman arm (refer to Figure 16 for details).

3. The pitman arm should be adjusted with

reference marks aligned or to an angle of

2.5º towards front of vehicle (I-Beam axle) in

relation with the vertical axis. If not, unscrew

and remove fixing nut. Remove the pitman

arm according to the procedure outlined

under previous heading "Pitman arm

removal". Adjust to the proper angle.

4. When adjustment is achieved, replace fixing

nut and tighten

TORQUE: 470-570 lb-ft (637-773 Nm)

11.4 TAG AXLE UNLOAD - SWITCH

ADJUSTMENT

1. Make sure vehicle wheels are straight and

facing forward.

2. Line up switch lever with reference to the

bracket center (Refer to Figure 18).

FIGURE 18: TAG AXLE UNLOADING SWITCH

ADJUSTMENT

14061

Loading...

Loading...