SECTION 10: FRONT I-BEAM AXLE

D DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

6. SERVICE INSTRUCTIONS FOR STEER

AXLE

6.1 STEERING KNUCKLE KINGPIN

INSPECTION

Check permissible slackness in the kingpins as

follows:

Aspects to be considered are:

• Lateral slackness

• Vertical slackness

Before commencing checks, apply parking

brake, raise wheels off ground and support axle

on stands.

6.1.1 Checking Lateral Slackness

Following regular and thorough greasing

practices will maximise bushing life. This

procedure measures the upper bearing & lower

bushing wear due to side and vertical loading.

While this is being carried out, the brake must be

applied.

1. Place a set-square with its stock on ground

and its blade against tire wall.

2. Place a mark on the ground to indicate

position of stock end.

3. Insert a lever through bottom cut-out of

wheel and lever it upwards thus moving set-

square outboard.

4. Mark the changed position of the stock end.

5. Maximum allowable stock displacement for

22.5" wheels is 0.315 in (8mm).

6. If displacement exceeds stated allowance

then need for bushing / bearing attention and

possible renewal, is in evidence.

To avoid inaccurate measurements, be careful

not to let the knuckle turn while moving

assembly in and out. Applying brakes will help

lock wheel assembly.

6.1.2 Checking Vertical Slackness

1. This is measured by a dial indicator

anchored to axle beam and having its

pointer placed vertical against knuckle top.

2. Place a jack against underside of knuckle

and, while applying a lifting force, observe

any movement on indicator dial.

3. If vertical movement is evident and it

exceeds 0.030” (0.76mm) then

readjustment of knuckle is required by

adjusting thickness of bearing adjusting

shims. In this case, refer to:

Dana Parts & Service Instructions S84U Steer

Axle KING PIN REWORK_ Manual NO 1985 B

iss A.

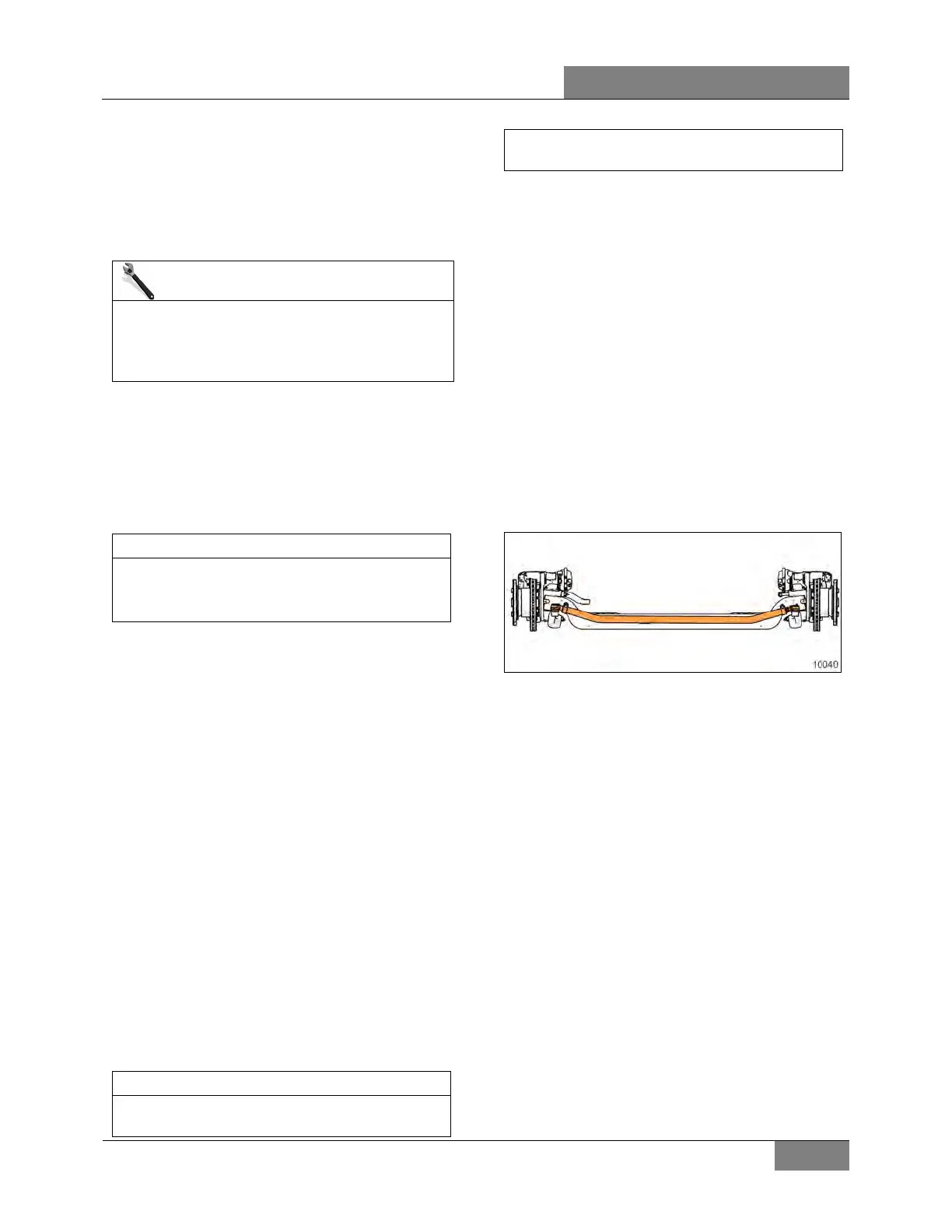

6.2 STEERING TIE ROD INSPECTION

FIGURE 3 TIE ROD

The steering tie rod on the axle requires several

visual and functional inspections. Refer to

Section 14– STEERING under heading FRONT

I-BEAM AXLE TIE ROD.

Detailed information can also be found in the

following supplier publication:

TRW_Front_Axle_Steering_Bar_Service_Info

rmation_XSZ143

MAINTENANCE

An inspection should be made at the intervals

specified by the Lubrication And Servicing

Schedule in Section 24: LUBRICATION &

SERVICING.

Loading...

Loading...