DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 01 revised Jan 2021

5. Replace noisy idlers or if a play is found.

Replace the automatic belt tensioner as a

complete unit.

6. Record the results of the inspection.

4.2 AUTOMATIC BELT TENSIONER

BUSHING WEAR

Automatic belt tensioner bushing wear may

result in belt misalignment.

1. Check the automatic belt tensioner T-1 thru

T-3.

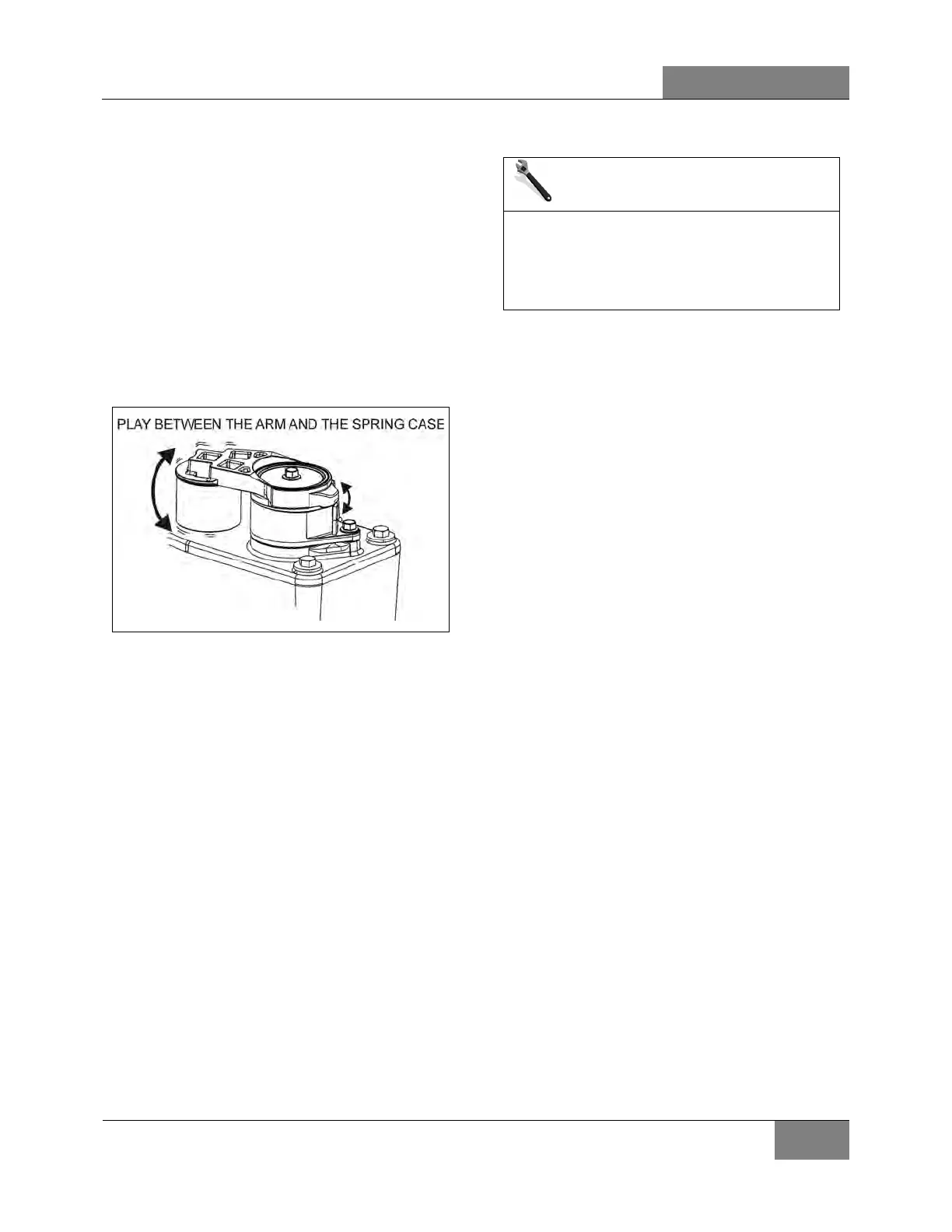

2. Pry the automatic belt tensioner arm and

check for a play between the arm and the

spring case (

FIGURE 25).

FIGURE 25: CHECKING BUSHING WEAR

3. If bushing wear is suspected, remove the

tensioner. Inspect the tensioner for any

signs of wear. Check for bearing noise as

well as metal to metal contact between the

arm and spring case which is a sign of

bushing wear. Check for cracks in the

tensioner body.

4. Replace the automatic belt tensioner if found

defective.

5. Record the results of the inspection.

4.3 BELTS AND IDLERS VISUAL

INSPECTION

1. Inspect drive belts for cracks, frayed

material, missing chunks in the belt,

abrasion and peeling. Replace belts if

damaged.

2. Visually inspect all idlers for signs of

deterioration, loose fasteners, etc.

3. Record the results of the inspection.

MAINTENANCE

Visually inspect belts and idlers for signs of

deterioration, cracks, frayed material

at the

intervals specified by the Lubrication And

Servicing Schedule in

LUBRICATION & SERVICING SCHEDULE.

Loading...

Loading...