SECTION 05: COOLING SYSTEM

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

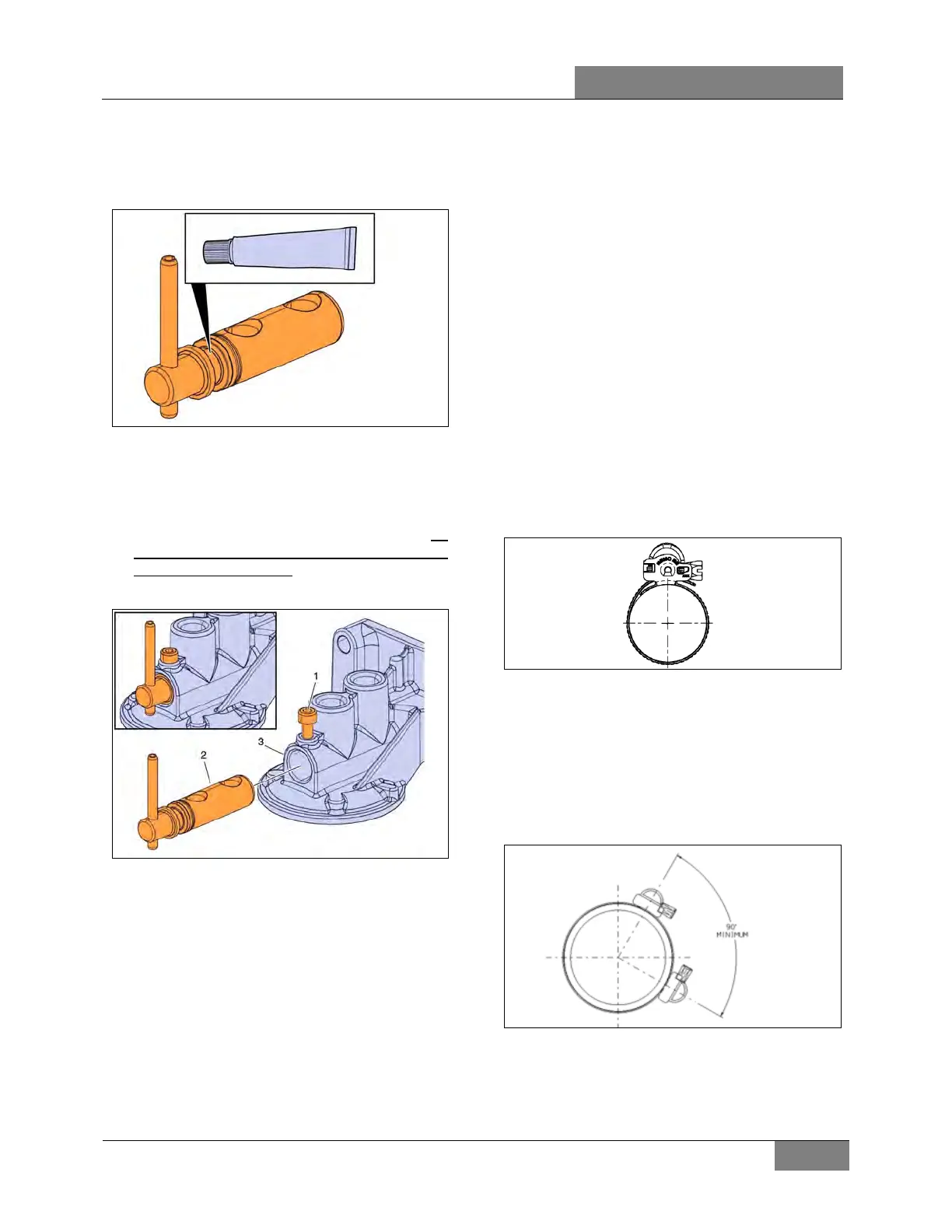

10. Apply grade NLGI No.2 silicone-based

grease to the grooved area of the spindle.

Ensure the grooved area of the spindle is

filled as completely as possible (Figure 9).

FIGURE 9: APPLY GRADE NLGI NO.2 SILICONE-BASED

GREASE TO THE GROOVED AREA

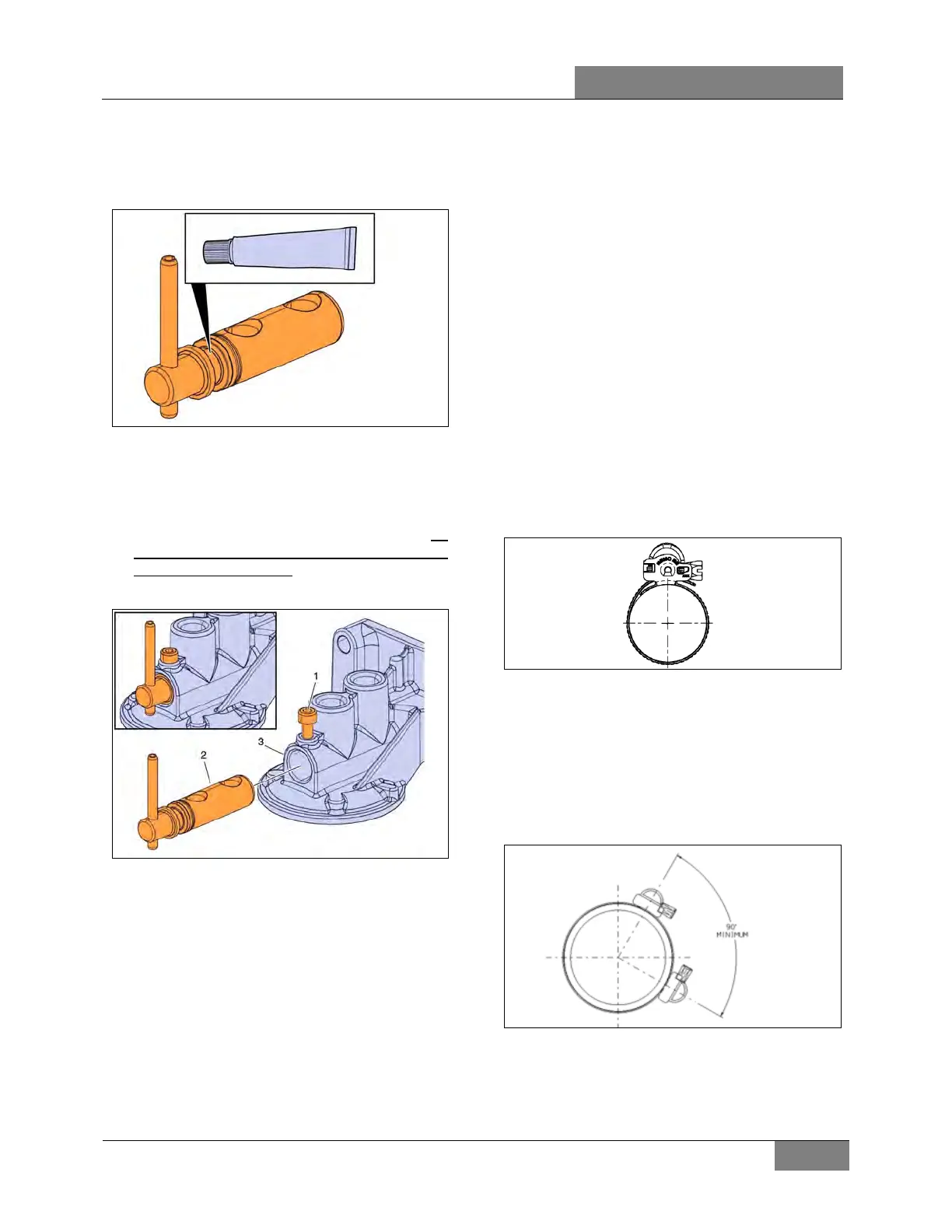

11. Reinsert the spindle (2) into the coolant filter

housing (3) and tighten the M5 hex socket

screw (1) (Figure 10).

12. To prevent reoccurrences, at a minimum, the

grease should be repacked in this area when

the coolant is changed, and the valve should

be rotated periodically.

FIGURE 10: INSERTING THE SPINDLE

13. Fill the cooling system with the recommended

coolant.

14. Set the engine stop/ignition interlock back to

the normal position.

15. Start the engine, check for leaks and proper

operation.

16. After shutdown, replenish coolant as

necessary.

4. HOSES

Rotten, swollen, and worn out hoses or loose

connections are frequent causes of cooling

system problems.

Serious overheating is often caused by an old

hose collapsing or from rotten rubber shedding

from hoses and clogging the coolant passages.

Connections should be inspected periodically

and hose clamps tightened. Replace any hose

found to be cracked or swollen.

4.1 HOSE CLAMPS ON COOLANT LINES

All hose clamps used for the heating and cooling

systems have a spring function (spring in the

housing) to compensate for the normal

expansion/contraction of hose and metal

connection that occurs during vehicle operation

and shutdown. These clamps are worm-driven

and made of stainless steel (Figure 11).

FIGURE 11: CLAMP TYPE USED ON HEATING &

COOLING SYSTEMS

All connections equal or greater than 2 inches

OD have doubled clamps (two clamps, side by

side) with screw housing separated from at least

90°. A torque wrench should be used for proper

installation (Figure 12 & Figure 13).

TORQUE: 30 lb-in (3.39 Nm)

FIGURE 12: DUAL CLAMP MINIMUM SPREAD ANGLE

Loading...

Loading...