DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

5. If there is no corrosion or damage to the

sealing boot or dirt seal, smear the steering

arm with Lithium grease and push seal back

into its properly seated position.

When dismantling the drag link, ensure that no

damage is caused to the sealing boots, dirt

seals or ball joint housings.

13.10 STRAIGHT BODY TYPE BALL JOINT

This type includes ball joints where the threaded

shank is slightly bent like those that are found

on the tie rod and draglink.

FIGURE 36: STRAIGHT BODY TYPE BALL JOINT

13.10.1 Visual Inspection

• Visually inspect for missing or damaged

grease fittings and replace if required.

• Damaged sealing boot or improper sealing

requires seal replacement or complete

replacement.

• Check ball joint connection for missing

cotter pins.

• Check for looseness in the ball/socket

assembly.

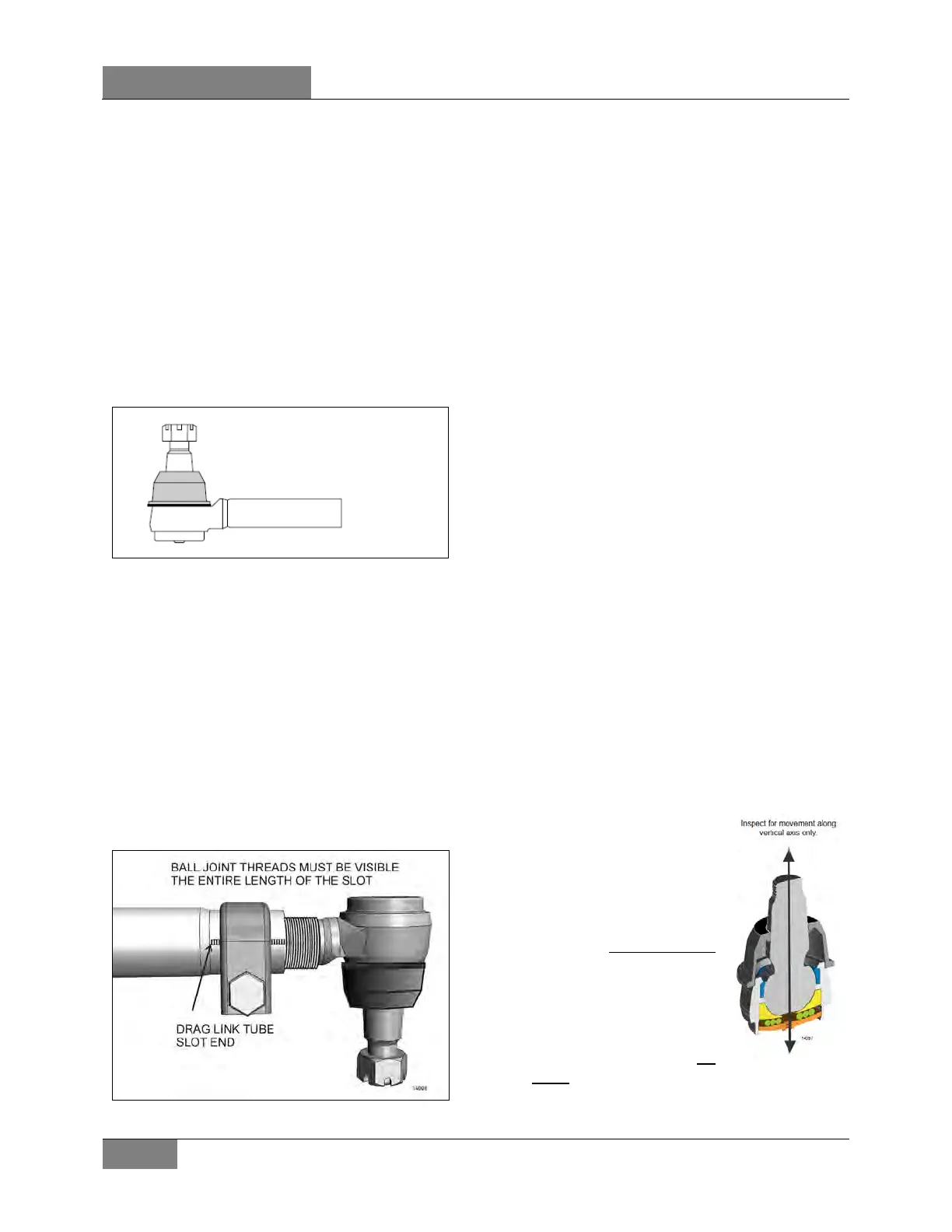

FIGURE 37: ADEQUATE CLAMPING CONDITION

For adequate clamping, the ball joint threads

must be visible the entire length of the tube slot.

If not, the tube must be adjusted or replaced. It

is either the wrong size, or improper adjustment

was used to compensate for another problem

(e.g. bent steering components).

No heavy corrosion is accepted for the clamps or

screws.

Nuts and screws must be firmly in place.

13.10.2 Straight Body Type Ball Joint End Play

and Looseness

What creates movement in sockets?

In each straight body type ball joints, the

compressive force of the spring creates resistive

torque by applying a constant load on the

bearing and stud.

As wear occurs on the components, the spring

creates less resistive torque. With less torque,

you no longer have the precise joint needed for

optimum steering, but you do still have a safe

linkage. When all compression is lost, it’s

time to replace the linkage. This wear can be

caused by impact, lack of lubrication and normal

wear.

1. With vehicle engine on, lightly rock the

steering wheel while checking for looseness

in any threaded joint. Observe any

looseness in the two mating tapers or any

movement of the ball pin nut. Any looseness

requires further inspection. If either of the

mating tapered parts shows distortion or

wear, both parts must be replaced.

2.

wheels straight ahead and

no force is being exerted

on the linkage by the

steering gear, push and

pull the ball joint in and

out by hand

force)

the bal

movement is detected, the

ball joint is safe. Any

movement detected by

hand will require the

replacement of the ball

joint.

Loading...

Loading...