DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

Ball pin

External joint shell

Radial cracking of the

sheet-metal race

Par

tial separation

is permitted

FIGURE 7: BALL PIN BUSHING

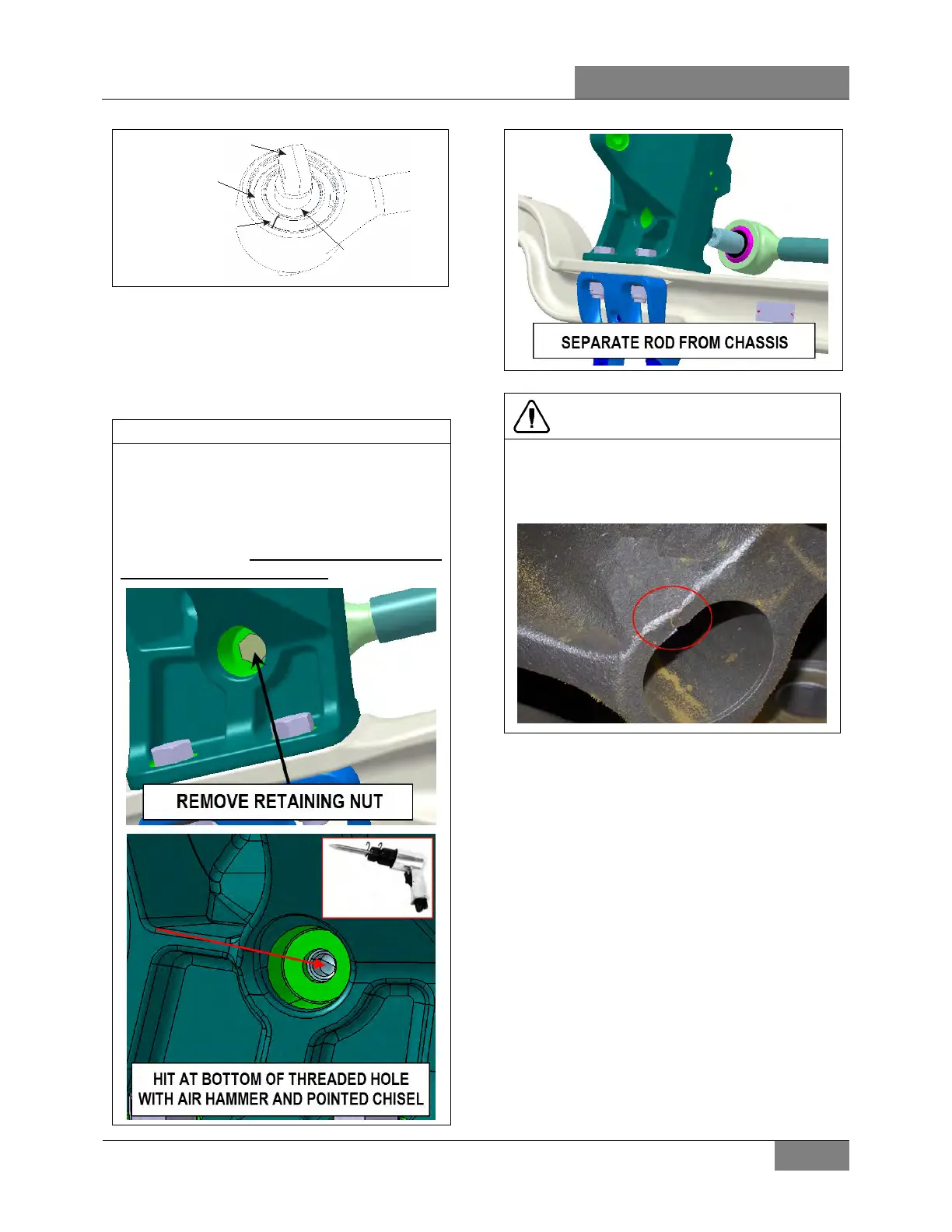

3.3.2 Radius Rod Removal

1. Unscrew the nuts (or bolts) at each extremity

of the radius rod.

2. Remove the radius rod.

One end of the transversal radius rod is fitted

with a conical (taper) pin that will require the

use of an air hammer and a pointed 13mm

(1/2inch) diameter chisel to remove it from the

chassis (after the retaining nut is removed

from the rod end). Care must be taken not to

damage the rod pin threads.

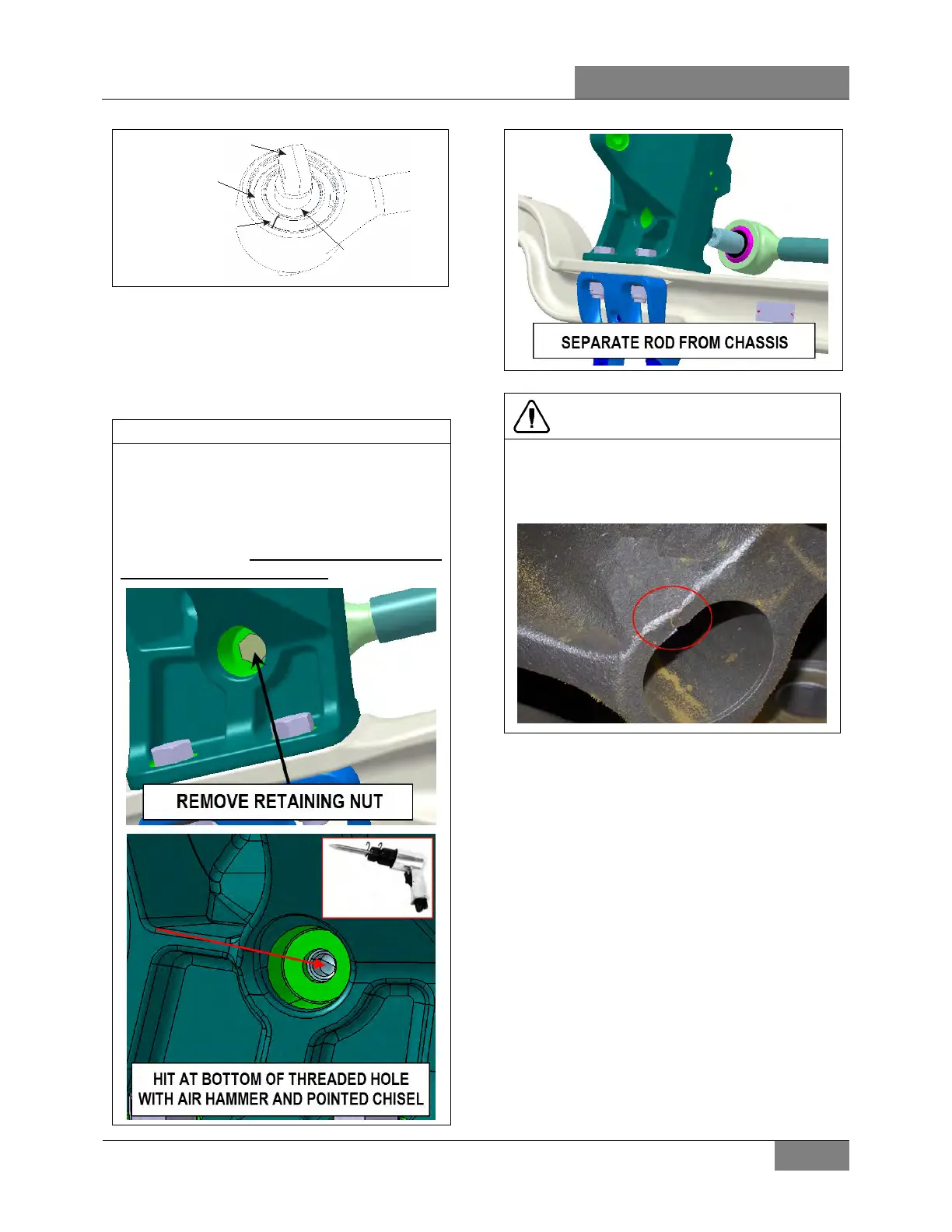

CAUTION

Do not hit the cast parts

disengage taper radius rods; this could lead to

cracking and/or deformations of the cast

parts.

3.3.3 Stripping Down

Strip down the defective joint by removing the

Circlip, and ball pin/bushing assembly.

Clean out housing bore and Circlip groove.

3.3.4 Radius Rod Assembly

The assembly work may be done only by a

recognized specialized workshop. Ensure that

old and new parts do not get mixed up with each

other. For this reason, all the old parts are to be

scrapped immediately after a joint has been

stripped down.

A complete repair set must be used for each

joint repaired, i.e. use of only part of a repair set

is not permissible.

Execute assembly of the new joint parts in the

following sequence:

Loading...

Loading...