DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

1. Complete lubrication of the contact surface

between housing bore and ball pin elastomer

through application of grease.

Apply the supplied grease, only if you are

using a repair kit.

2. Insert ball pin/bushing, assembly. Ensure

that the bolt bores are in the correct position

in relation to the axis of the tube.

3. Place joint in receiving fixture and mount

annular assembly tool on the housing. Then

locate Circlip in the housing using axial load

with the aid of the assembly matrix.

4. Opening of the Circlip is located at 45° to the

housing shaft axis. Make sure that the

Circlip is perfectly engaged in the housing.

3.3.5 Radius Rod Installation

1. Snug up the nuts (or bolts) and repeat at the

other end.

2. Refer to heading "Suspension Height

Adjustment" later in this section, and set the

vehicle to normal ride height.

3. With the vehicle at normal ride height,

tighten all radius rod anchor studs nuts or

bolts to specification.

RADIUS ROD NUT/BOLT

TORQUE: 225-255 lb-ft (305-346 Nm)

RADIUS ROD STUD

TORQUE: 90-110 lb-ft (122-149 Nm)

TRANSVERSAL RADIUS ROD (CONICAL)

TORQUE: 185-227 lb-ft (251-308 Nm)

CAUTION

It is extremely important upon reconnection of

the rods that the proper clearance height

between the axle and body be maintained.

Otherwise, the rubber bushings in radius rod

ends will become preloaded, thus reducing

their life span.

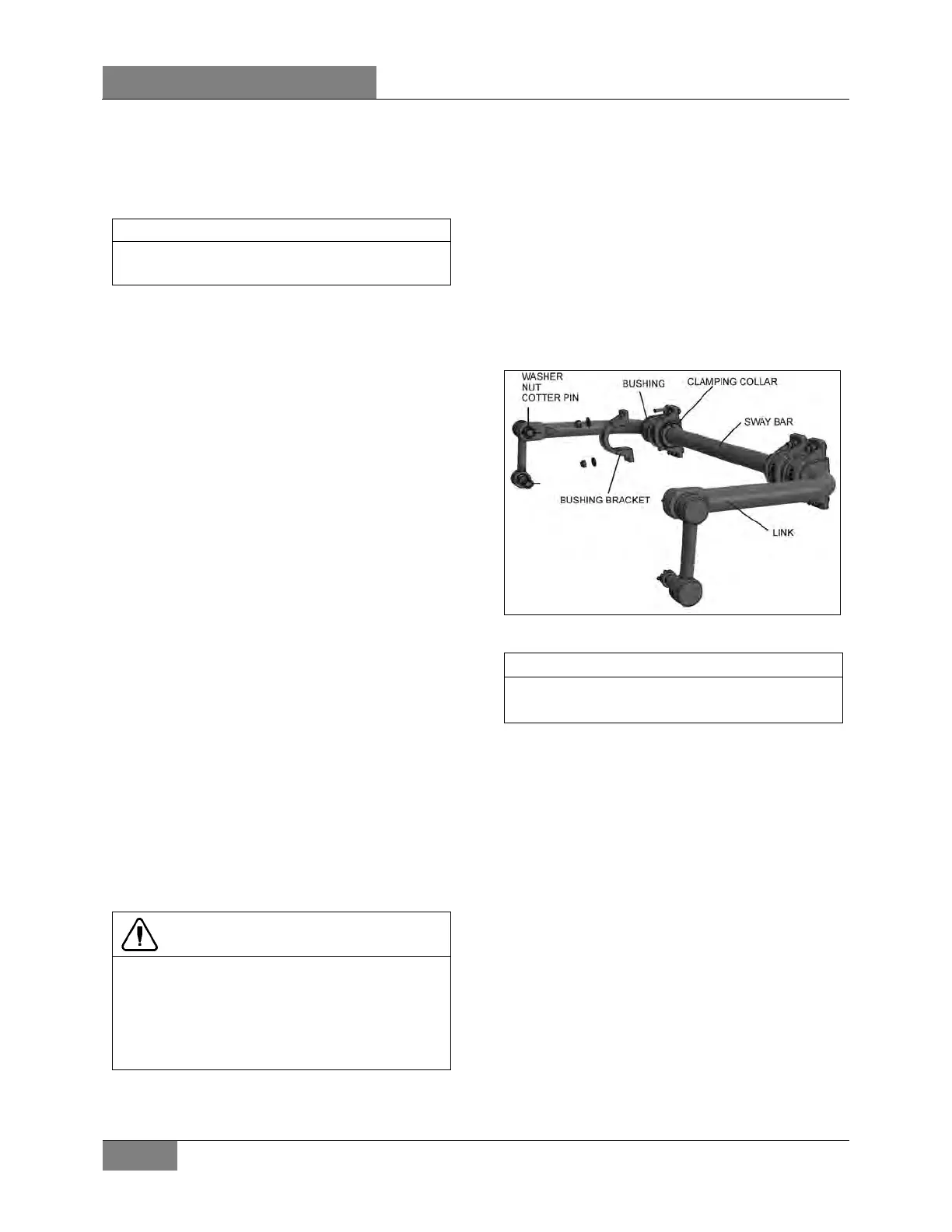

3.4 SWAY BAR

A sway bar is connected to the front axle to

increase vehicle stability. It controls lateral

motion (swaying movement) of the vehicle

(Figure 8).

3.4.1 Removal

1. Disconnect the two links from sway bar.

2. Safely support the sway bar. Unbolt the four

bushing brackets from subframe.

3. Remove sway bar.

FIGURE 8: SWAY BAR 16028

Sway bar bushings are slit to ease their

removal.

3.4.2 Installation

1. Loosely install the sway bar.

2. Tighten the eight bushing brackets nuts

according specifications.

TORQUE: 80-100 lb-ft (108-136 Nm)

3. Tighten sway bar link upper nuts and lower

nuts according to specifications & install a

cotter pin on each nut.

TORQUE: 165-200 lb-ft (224-271 Nm)

Loading...

Loading...