16

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

8.2 REPAIR USING FIBERGLASS PASTE

Fiberglass paste is used for repairing small

dents, scratches, and pits. Paste is made by

mixing resin, hardener and fiberglass strand or

filler to the consistency of putty. Where it may be

necessary, sand paint away around damaged

area. On underside of coach, scrape away

undercoating from damaged area, and wipe

clean with solvent.

Preheat the area to be repaired using heat

lamps. Mix desired quantities of resin and

hardener according to manufacturer's

instructions. Add powdered fiberglass strand into

mixture to thicken it into a putty state.

If repair is made on a vertical surface, adding

powdered filler material to mixture will reduce

the tendency of hot resin to flow or run.

Apply the material with a putty knife or similar

object, building material up to the desired

contour. For deep filling and on vertical surfaces,

several layers of material may be used.

A hacksaw blade, held flat to adjacent contour

and then moved in a sawing action across the

repair when the resin is in a gel state, will

remove excess resin from repair. Finish repair

with the same procedure as when using

fiberglass cloth.

8.3 TYPICAL FIBERGLASS REPAIR

PROCEDURE

Remove all loose particles or damaged material

using a power sander or rasp. Clean area,

overlapping hole approximately 1" to 1-½" (25-40

mm) all around. Remove all dirt, grease and

paint from area to ensure good bonding surface.

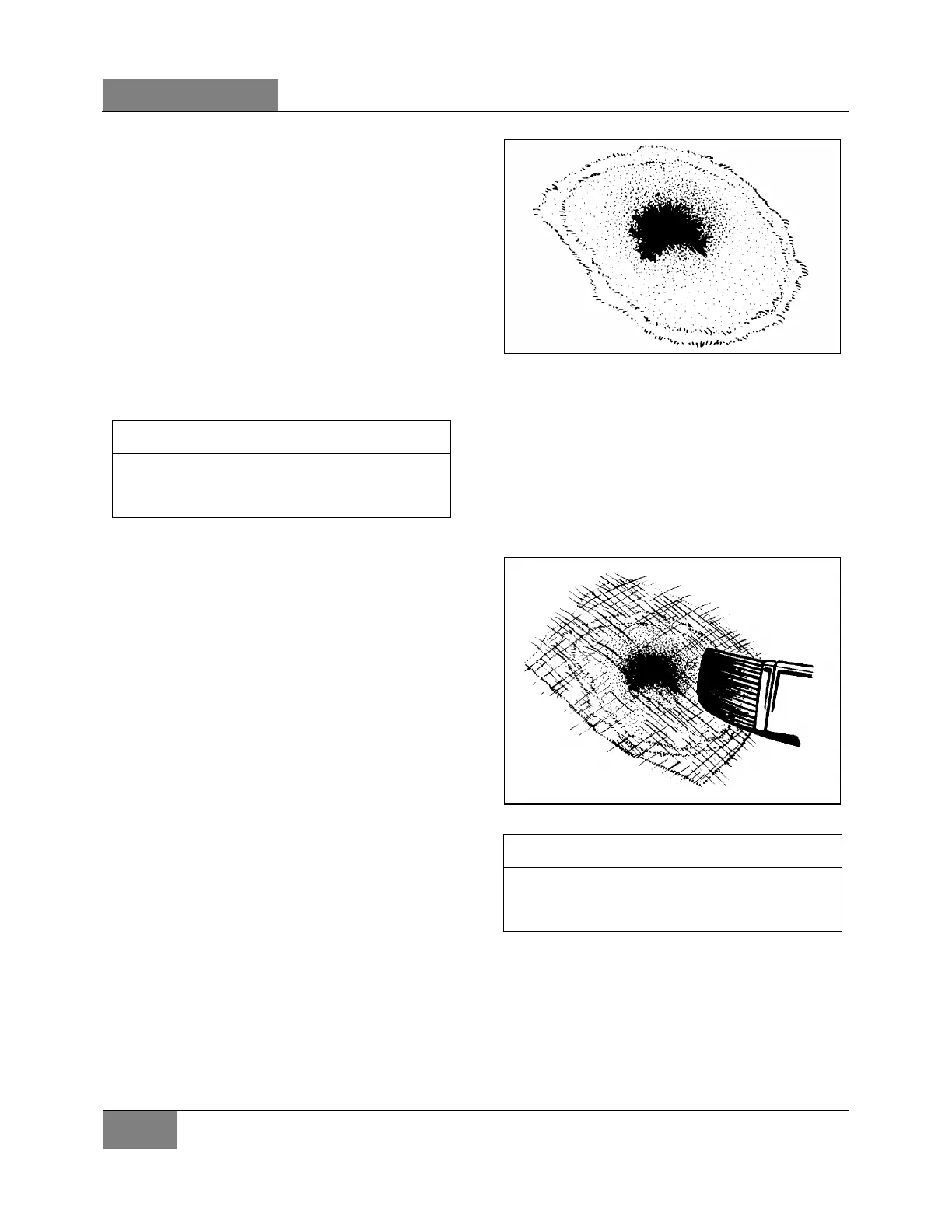

Feather the cleaned area all around (Figure 2).

FIGURE 2: FIBERGLASS REPAIR 18089

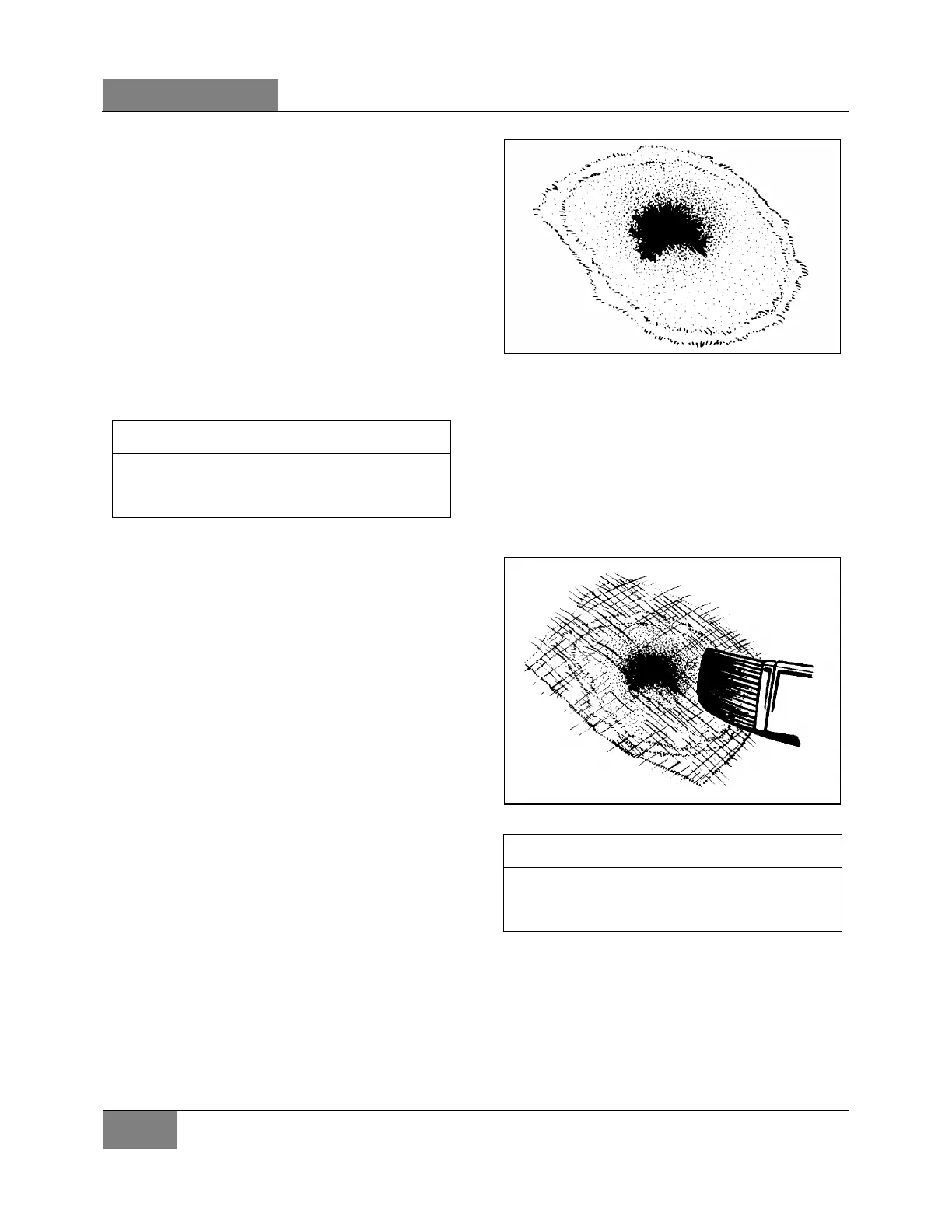

Cut a piece of fiberglass mat slightly larger than

area being repaired. Impregnate mat with

general purpose polyester resin catalyzed

normally. Use a clean paint brush to apply the

polyester resin. Apply impregnated mat over hole

and press onto surface with brush to obtain good

adherence. Another coat of general purpose

polyester resin can be applied at this time

(Figure 3).

FIGURE 3: FIBERGLASS REPAIR 18090

Remove all air between surfaces being joined.

Allow area to harden and sand surface to

remove any wax.

Apply another mat, followed by a cloth patch,

and another mat. All layers must be thoroughly

impregnated with polyester resin, brushed well

and free of air. Apply more layers of mat and

cloth as required until the desired strength and

thickness is obtained, minimum two 1-½ oz

(43 g) mats and one 9 oz (255 g) cloth (Figure

4).

Loading...

Loading...