SECTION 22: HEATING AND AIR CONDITIONING

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

Empty the shaft seal oil collecting tube at the

intervals specified by the

Servicing Schedule in Section 24A.

During the 250-hour run-in period of the shaft

seal, an increased oil seep rate may occur.

FIGURE 17: SHAFT SEAL OIL COLLECTING TUBE

4.1.4 Maintenance - Oil Color & Level Check

Check the oil color and the oil level, top up as

needed. Change the oil if it has darkened (see

oil evaluation criteria below).

A/C compressor oil color & level check

Check compressor oil color and level

intervals specified by the

Servicing Schedule in Section 24A.

1. Run the compressor for at least 15 minutes,

the time required so that the oil gets clear,

unclouded and stabilized (without bubbles).

2. Check the oil level during operation. The

proper level is:

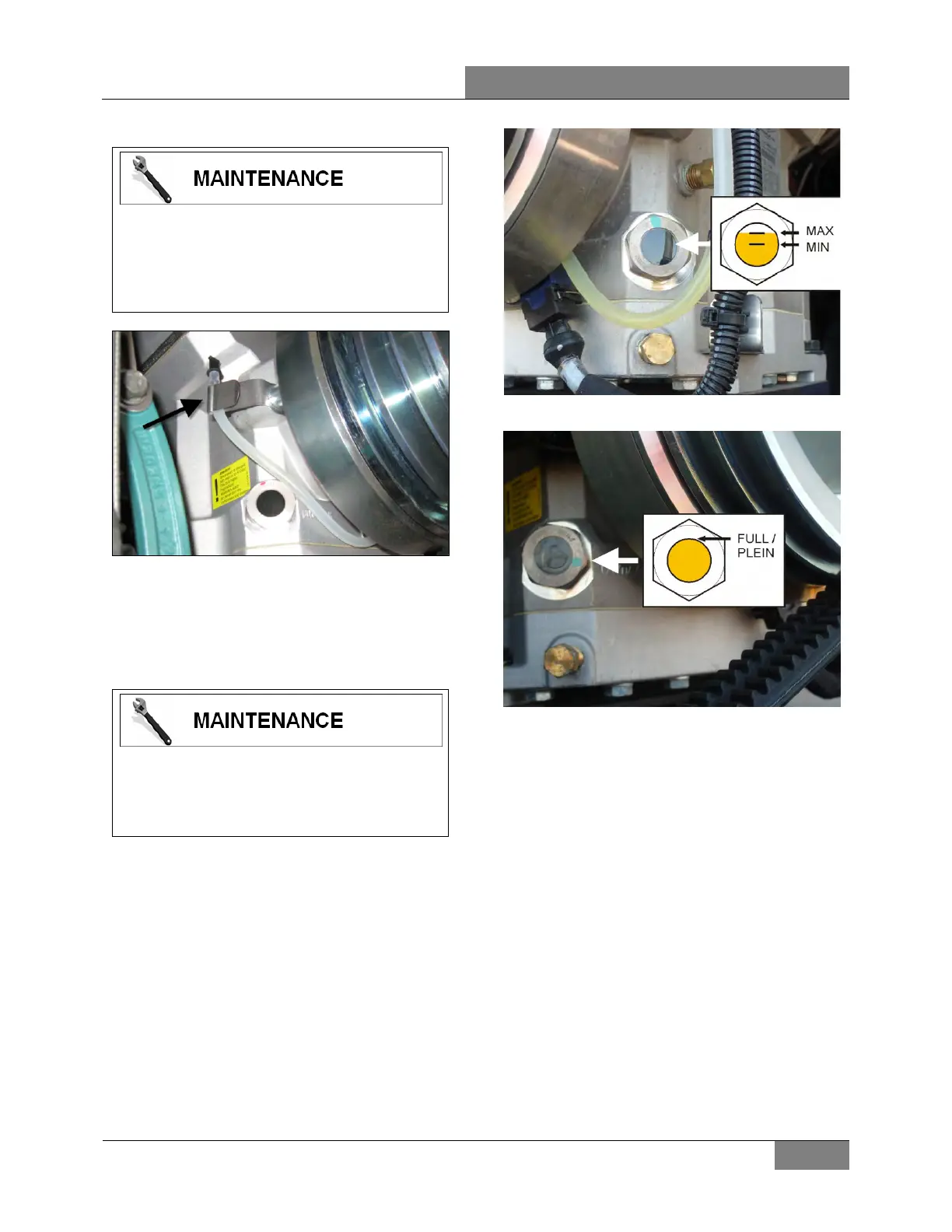

• R.H. sight glass: between ½ and ¾ of

sight glass height (Figure 18).

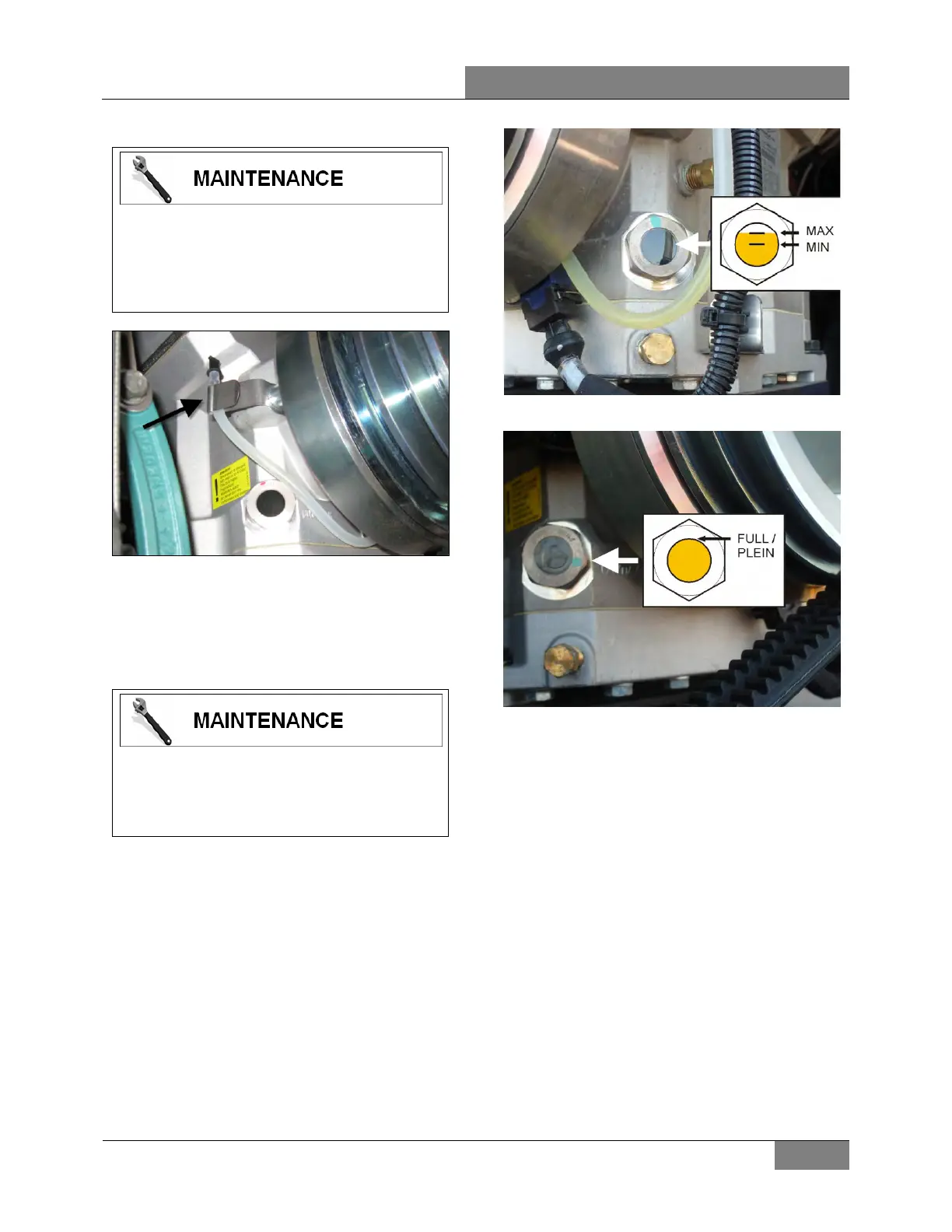

• L.H. sight glass: the full sight glass height

(Figure 19).

FIGURE 18: R.H. SIGHT GLASS

FIGURE 19: L.H. SIGHT GLASS

The oil level is expected to remain the same

over time except if there is a loss of refrigerant.

Adding oil must be done by taking the same

precautions as when changing oil in order not to

introduce the moisture content of the ambient air

in the air-conditioning system.

3. Check for discoloration of the oil. It should be

clear and light in color. Darkened, cloudy and

contaminated oil must be changed.

Diagnose the problem. See the following

images to help you evaluate the state of the

compressor oil.

Loading...

Loading...